How to Identify Car Wire Connector Types for Specific Uses

Understanding the types of wire connectors in automotive applications is crucial for effective car maintenance. These connectors facilitate communication and power distribution between components. Modern vehicles can feature up to 700 connectors, highlighting their significance. There are various types of connectors designed for specific tasks, including wire-to-wire and board-to-board connectors, which are essential for optimal vehicle performance. Familiarizing yourself with these automotive wire connectors can enhance your ability to repair and maintain your car efficiently.

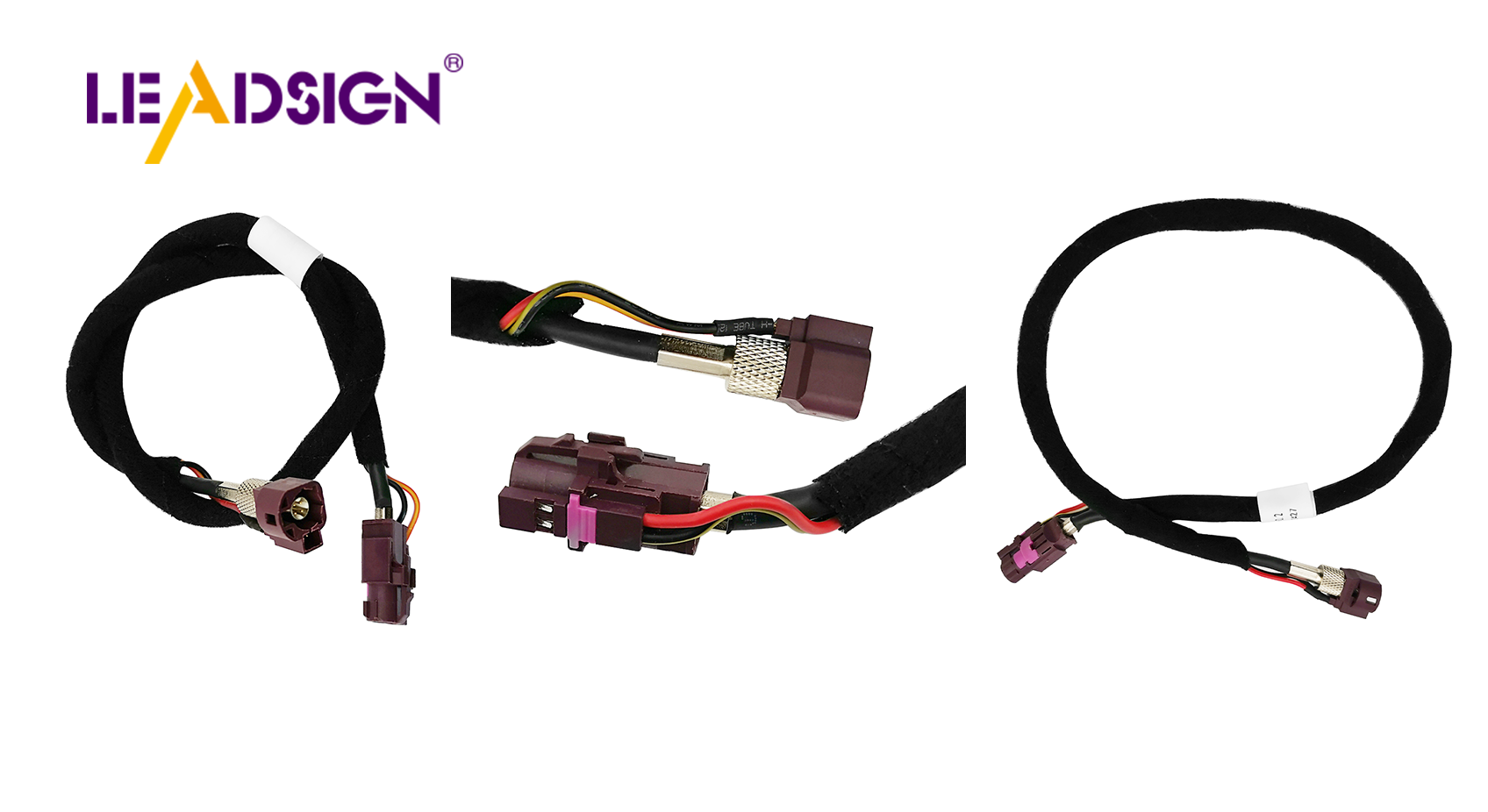

Common Types of Wire Connectors in Cars

Knowing car wire connectors is important for fixing electronics. These connectors help parts work together smoothly. Let's look at some common types.

Blade Connectors

What They Are Like

Blade connectors are very common in cars. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect, perfect for quick fixes. They come in different sizes and materials to fit various needs.

Where They're Used

You often see blade connectors in car lights like headlights. They're also used with fuse boxes and relays because they're easy and reliable.

Bullet Connectors

What They Are Like

Bullet connectors are shaped like bullets and fit tightly into sockets. This keeps them from coming loose easily. They're made from strong materials to handle shaking and stress.

Where They're Used

In cars, bullet connectors are used in wiring harnesses and speakers. Their tough design is great for places with lots of movement, like near engines.

Butt Connectors

What They Are Like

Butt connectors join two wires permanently. They're tube-shaped and need crimping to hold wires tight. They give a strong connection, which is crucial for car wiring.

Where They're Used

You use butt connectors when fixing or adding wires in tight spaces, like under dashboards. Their permanent hold ensures they last long.

By learning about these car wire connectors, you can fix vehicle electronics better. Each type has special uses to keep cars running safely and well.

Picking the Best Connector

Choosing the right car wire connectors is key for your car's electrical system to work well. Think about a few things to pick the best one.

Power Needs

Current and Voltage Matching

Match the connector with your car's power needs. Each type handles certain current and voltage levels. Using a wrong connector can cause problems. Always check if it fits your car's system.

Wire Size Fit

Wire size fit is important. Connectors must match wire size for a good connection. Wrong sizes can lead to bad connections and dangers. Measure wire size right and pick connectors made for that size.

Environment Conditions

Heat and Weather Toughness

Cars face tough conditions. You need connectors that handle heat and weather changes. Find ones made from strong materials for all climates. This keeps them lasting long.

Movement and Stress Resistance

Cars move a lot, causing stress on parts. Pick connectors that handle this stress well. Good ones are strong to stop loosening or breaking. Buying these keeps your car working safely.

Scientific Research Findings: Spending on good connectors helps with electrical work and lasting use. Design affects how well they work over time.

By knowing these tips, you can choose the right car wire connectors for you. This helps keep your car safe and running well.

Troubleshooting and Maintenance

Taking care of your car's wires is important. Knowing the types of connectors helps. Checking them often keeps your car working well.

Finding Common Problems

Signs of Wear and Damage

Look at your car's wire connectors for damage. Check for rust, color changes, or broken wires. These mean the connector might not work right. Bad connectors can make your car run poorly. Fixing them early stops bigger problems later.

Connections fail if they are loose.

Connections fail if they are loose. Loose ones cause flickering lights or electronics not working right. Make sure all are tight and secure. If any are loose, fix them quickly to avoid more issues.

Good Maintenance Habits

Regular Inspection and Cleaning

Check and clean wire connectors often. Dirt can build up and cause bad connections. Use a soft brush or air to clean gently. This keeps connections strong and lasts longer.

Proper Installation Techniques

Follow instructions when installing wire connectors in cars. Use the right tools to avoid breaking them. Crimping well stops them from loosening with movement.

Industry Insight: Cars now use more electronics needing good connectors. Using original parts helps keep your warranty safe.

By learning these tips, you can manage car wire connectors well. This keeps your car safe on the road.

Understanding car wire connectors is key to keeping your car's electrical parts working. You've learned about different types and their uses. Now, use this knowledge in real life to make your car better.

Testimonial: *OEM connections are high quality and last long, cutting down on repair costs and time.*

Look for more information or ask an expert for tough problems. This careful approach keeps your car safe and reliable.

See Also

Exploring HSD Connectors in the Automotive Sector

Navigating Ford Fakra Connectors

In-Depth Analysis of HSD Connectors

Complete Overview of Fakra Connectors: Fundamentals, Varieties, and Uses

Significance of FAKRA Connectors in Automotive Implementations