How to Identify Automotive Wiring Connector Types for Replacement

Finding the right automotive electrical connectors types is important for your car's safety and performance. Connectors may require replacement due to wear and tear, exposure to harsh weather conditions, or malfunctioning. These issues account for 45% of connector problems. Pay attention to the shape, color, and number of pins when identifying the correct connector type. Refer to manuals or online resources for additional guidance. This ensures secure connections, reduces the risk of failures, and prolongs the lifespan of your vehicle.

Understanding Automotive Electrical Connectors Types

Knowing about automotive electrical connectors types is key for your car. These connectors help different parts of your car talk and work well together. Let's learn about the types, materials, and uses of these connectors.

Types of Automotive Electrical Connectors

There are many kinds of automotive connectors. Each has a special job. Here are some common ones:

Blade Connectors

Blade connectors are flat and rectangle-shaped. You find them in fuse boxes. They connect well and are easy to use.

Pin Connectors

Pin connectors have round pins that fit into sockets. They are used in engine controls and sensors. They stay connected even when things shake.

Bullet Connectors

Bullet connectors look like small bullets. They connect wires in tight spots. You can disconnect them fast, which helps with repairs.

Butt Connectors

Butt connectors join two wires end-to-end. They're used for fixing wires or changing them. They're simple but work well.

Connector Materials

The material affects how long a connector lasts and works:

Plastic Connectors

Plastic ones are light and don't rust easily. They're good where there's water, but not for high heat.

Metal Connectors

Metal ones are strong and conduct electricity well. They're great for hot or shaky places.

Connector Functions

Knowing what each connector does helps you pick the right one:

Power Connectors

Power connectors move electrical power around. They handle big currents, like in batteries.

Signal Connectors

Signal connectors send data between car parts. They stop interference so data stays correct.

Ground Connectors

Ground connectors let current return to the battery safely. They stop faults and keep systems stable.

By learning about these automotive electrical connectors types, you can choose wisely when fixing or replacing them in your car.

Steps to Find Connector Types

Finding the right automotive electrical connectors types is key for your car's electric system to work well. Here are steps to help you find these connectors.

Look Closely

Start by looking closely. This easy step shows a lot about the connector type.

Shape and Size

Check the shape and size. Different connectors have unique shapes. Blade ones are flat rectangles, while bullet ones look like small bullets. Noticing these helps you choose right.

Color Clues

Colors give clues too. Many connectors use colors for their job or fit. Power ones might be red, ground ones could be black. Colors quickly show what they do.

Use Guides

If looking isn't enough, use guides for more help.

Manuals from Makers

Maker manuals have lots of info. They have diagrams and details of automotive electrical connectors types in cars. Checking them helps pick the right one.

Online Help

The internet has many resources for finding connectors. Websites and forums about car repair have guides and pictures to match your connector type. Use online tools to learn more.

Tools for Finding

Sometimes eyes and guides aren't enough, so use tools.

Multimeters

A multimeter checks a connector's electric parts by measuring voltage, current, and resistance to see if it works right. It's great for high-voltage automotive electrical connectors types.

Kits for Connectors

Connector kits are made just for this job with adapters and guides to match your connector type easily, saving time on tricky automotive electrical connectors types.

Car Experts say knowing when to change a connector is important for good car repairs.

By doing these steps, you can find the automotive electrical connectors types you need to replace confidently, helping repairs go smoothly and making your car work better.

Tips for Changing Connectors

Changing automotive electrical connectors types might seem hard, but with the right steps, it's easy. Here are some tips to help you.

Picking the Right Connector

It's important to pick the right connector. It needs to fit and work well.

Checking Compatibility

First, check if it fits. The new connector should match the old one in shape, size, and pins. This makes sure it works right. Look at your car's make and model to choose better. Connectors Experts say to look at keyways and tabs on connectors to know their type. This stops wrong matches that cause problems.

Thinking About Quality

Next, think about quality. Choose strong connectors that last long. Good ones handle tough conditions better. Metal connectors are strong and conduct electricity well, great for hot places. Quality means safety and trust.

How to Install

After picking the connector, install it right by following these steps.

Getting Wires Ready

Start with wires readying. Strip wire ends carefully without harming them for a good connection. Clean wires if dirty or rusty for a solid link.

Fixing the Connector

Once wires are ready, fix the connector by inserting wires into it and crimping tightly using a proper tool for best results. A tight connector avoids loose links and failures.

Testing Connection

Testing is last; it checks everything works fine.

Continuity Check

Do a continuity check first using a multimeter to see if current flows smoothly through the connector; this finds breaks or faults in connections ensuring correct installation.

Load Check

Then do a load check; this sees if the connector handles electric load well under normal use giving peace of mind about its reliability.

Connectors Experts stress testing after installing as crucial saying "Knowing when to change a connector is vital for good car repairs."

Follow these tips to change automotive electrical connectors types confidently keeping your car's electric system safe and working.

First, look closely at the connector's shape and color. Count the pins too. Use guides and tools like multimeters for help. Picking the right connector keeps your car safe. It stops problems and helps your car run well. If you're not sure, ask a pro for help. A mechanic might say, "Fixing connectors makes repairs work better." Remember these tips for safe driving!

See Also

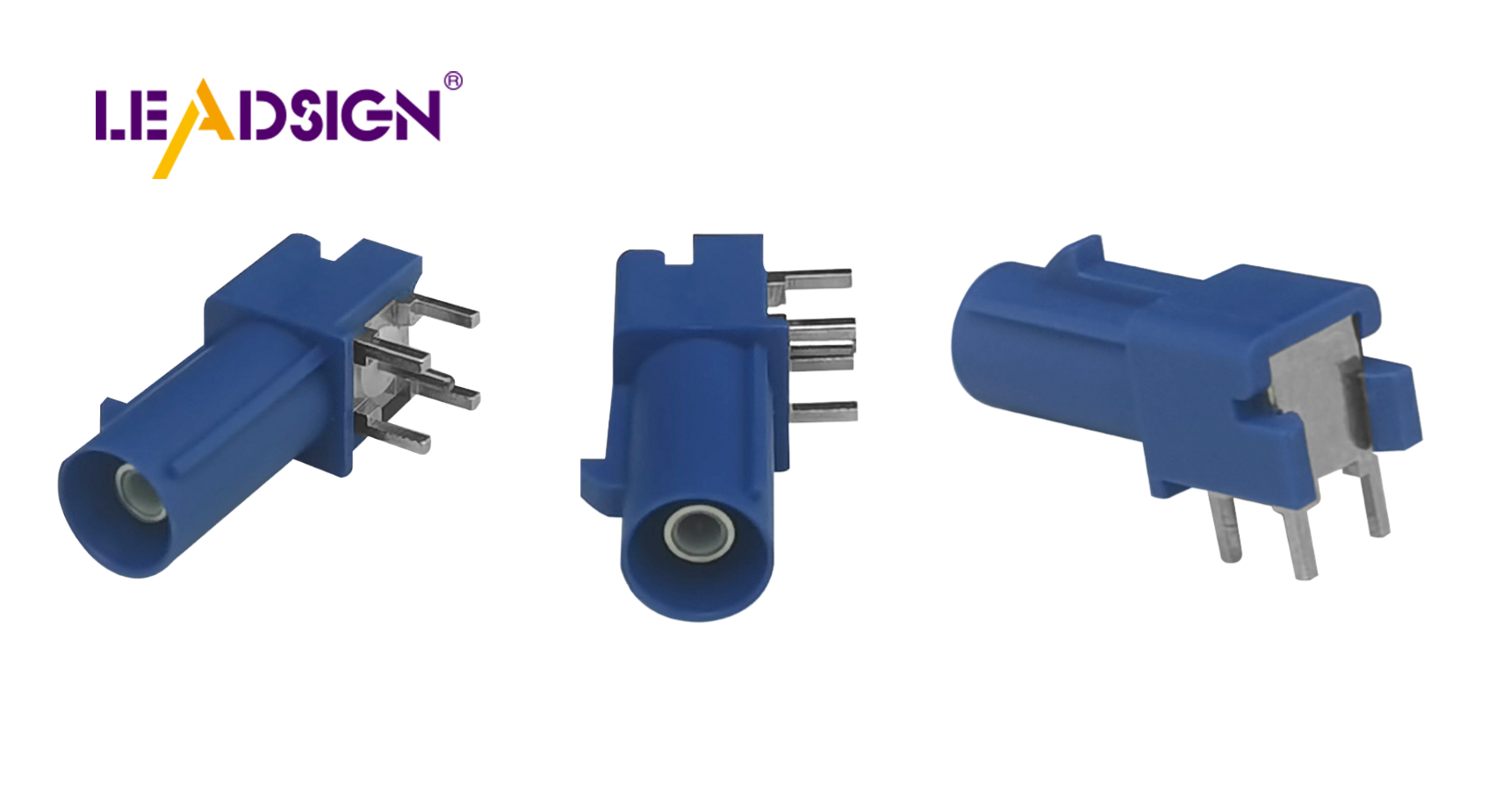

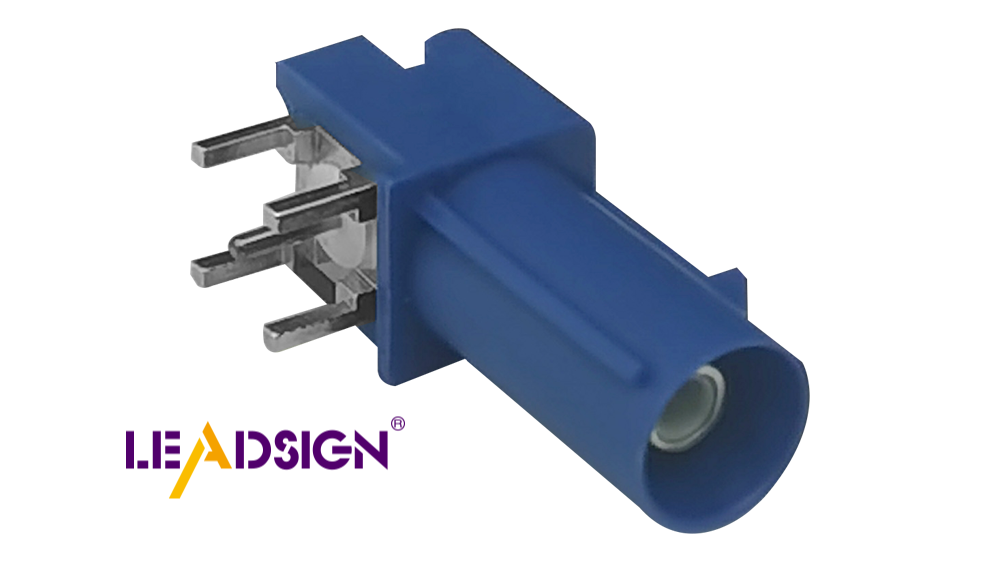

Exploring Ford Fakra Connector Essentials

Essential HSD Connector Insights for Automotive Sector

Significance of Fakra Auto Connectors in Contemporary Cars