How to Identify Automotive Wiring Connector Types for Replacement

Finding the right automotive electrical connectors types is very important for maintaining your car's electrical system. It helps ensure that everything works well and efficiently. You might need a new connector if there are issues with electrical contacts, which occur frequently with high-voltage connectors. Common problems include issues stemming from old connectors or damage caused by weather exposure. Understanding the different types of automotive electrical connectors available allows you to make informed decisions. These connectors come in various shapes and sizes, each designed for specific purposes. By familiarizing yourself with these types, you can ensure that your car's electrical connections are secure and dependable.

Understanding Car Electrical Connectors

When fixing car electronics, knowing connector types is key. These connectors help car parts talk to each other. Let's look at some common types and what they do.

Common Car Connector Types

Blade Connectors

Blade connectors are used a lot in cars. They have a flat metal piece that fits into a slot. You see them in fuse boxes and relays. They're easy to connect and disconnect, great for places needing lots of checks.

Pin Connectors

Pin connectors, or pigtail connectors, are for high power use. They have a pin fitting into a socket for strong connections. You find them in headlights and starters. They're tough and handle big electric loads well.

Bullet Connectors

Bullet connectors look like small bullets and link wires well. They're used in car lights and audio systems. Their round shape makes them easy to plug in or out, good for tight spaces.

Butt Connectors

Butt connectors join two wire ends together. They're used to fix car wiring. Crimping them on wires gives strong, safe links. This keeps the electrical system working right.

Materials Used

The build of car connectors affects how they work and last.

Plastic Connectors

Plastic ones are light and don't rust easily. They're used where there's moisture risk because they're good insulators, keeping things safe.

Metal Connectors

Metal ones like copper or brass conduct electricity well. They're best for high power needs as they carry big loads safely and last long.

Connector Jobs

Knowing what different car connectors do helps pick the right one.

Power Connectors

Power ones send electricity to parts of your car needing it most, like engines.

Signal Connectors

Signal ones pass data between gadgets like radios without messing up signals.

Ground Connectors

Ground ones let electricity go back to the battery safely, stopping faults.

By learning about these connector types, you keep your car's electronics running smoothly whether fixing or upgrading parts.

Steps to Find wiring connector types

Finding the right wiring connector is key for your car's electric system. Follow these steps to find the connectors you need.

Look at It

Start by looking at the connector to get clues.

Check Its Shape

Look at the shape of the connector. Different shapes mean different types, like rectangle or circle. This helps you know which one it is. For example, blade connectors are flat and rectangle, while bullet ones are round.

See Its Color

Next, look at its color. Many connectors have colors that show what they do. Colors help you know the type and job of the connector in your car's system. Red might mean power; green could mean ground.

Use Books and Websites

Books and websites help find exact connector types.

Maker Books

Check maker books for details about connectors. They have pictures and numbers to match your connector with a new one. Makers put diagrams in them to make it easier.

Online Help

Use online sites for more help. Car part sites have lists where you can search by shape or color. These are useful if you don't have books.

Tools That Help

Some tools can help find wiring connectors better.

Use a Multimeter

A multimeter tests electric connections. Use it to check if electricity flows through the connector right. This tells if it's working well and helps know its type by how it works with electricity.

Look at Pinout Pictures

Look at pinout pictures to see how wires connect inside it. These pictures show each wire's spot, helping identify the type of connector. You can find these in repair books or online too.

By doing these steps, you can find out which wiring connectors you need to replace easily. This keeps your car's electric system strong and working well.

Things to Think About for Replacement

When changing car wiring connectors, think about a few things. This helps keep your car's electrical system working well.

Compatibility

Making sure it fits is very important.

Matching Connector Types

First, know which connector you need. Different connectors do different jobs. If you need a blade connector, make sure the new one looks the same. This stops wrong connections.

Ensuring Electrical Compatibility

Check if the new connector works with your car's power needs. Look at voltage and current ratings. Using the wrong one can break parts or cause problems.

Quality and Durability

Pick good connectors for long-lasting use.

Choosing High-Quality Materials

Choose strong materials like copper or brass for metal ones. They conduct electricity well. Plastic ones are good insulators and don’t rust easily. Good materials stop future problems.

Weatherproofing and Insulation

Weatherproofing is key if connectors face tough weather. Find ones with good insulation to block water and dirt. This keeps them from rusting and ensures they work in bad conditions.

Installation Tips

Right installation makes connections safe and effective.

Proper Crimping Techniques

Crimping joins wires to connectors tightly. Use proper tools for this job to reduce resistance and keep electricity flowing right. Practice on extra wires if needed to get it right.

Ensuring Secure Connections

After putting them in, check if they’re tight by pulling gently on wires. Loose ones can cause electrical issues, so make sure everything stays put.

Expert Advice: Experts say talking to professionals helps when picking hard-to-find connectors for your car.

By thinking about these points, you can replace wiring connectors confidently, keeping your car’s electric system strong.

Finding and changing the right automotive wiring connectors is key to keeping your car's electric system working well. Follow these steps to make sure your car's connections stay safe and work properly. Here are some last tips for a good connector change:

Check compatibility twice: Make sure the new connector is like the old one in type and job.

Choose good materials: Pick top-quality connectors to stop future problems.

Ask an expert: If unsure, talking to a pro can save time and avoid errors. As happy customer, Rob Wickersheim, said, "David was awesome. Very careful and made sure this special connector would work for me."

By remembering these tips, you can easily handle connector changes and keep your car running well.

See Also

Exploring Ford Fakra Connector Essentials

Essential HSD Connector Insights for Auto Sector

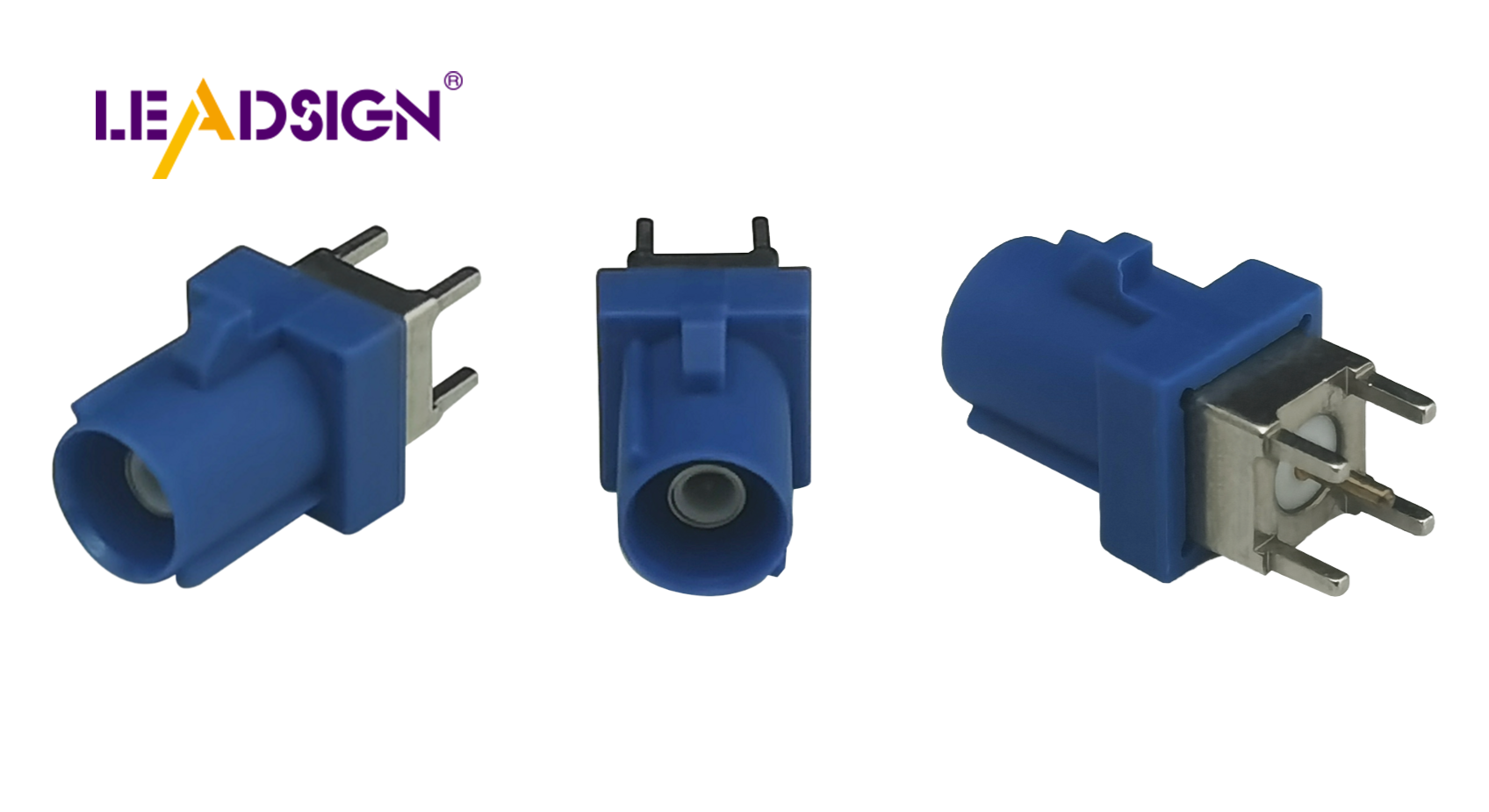

Significance of Modern Vehicle Fakra Connectors