How to Identify Automotive Wiring Connector Types for Replacement

Finding the right automotive electrical connectors types is crucial for maintaining your vehicle's electrical system. These connectors play a vital role in ensuring proper functionality. Whether due to aging, damage, or upgrades, automotive electrical connectors may require replacement. With various types available, identifying the specific type is essential for a successful replacement. This not only prevents electrical issues but also enhances safety.

Understanding Automotive Electrical Connectors

Knowing different car connectors is important for fixing car electronics. These connectors help electrical systems work right and safely. Let's look at the types, materials, and jobs of these connectors.

Types of Car Electrical Connectors

Car connectors come in many types, each with a job:

Blade Connectors

Blade connectors have flat metal pieces. They are easy to use and strong. You find them in fuse boxes and relay panels.

Pin Connectors

Pin connectors have round pins that fit into sockets. They are used in many car systems. They send signals and power well.

Bullet Connectors

Bullet connectors look like bullets. They are simple to connect and disconnect. You see them in lights and accessory circuits.

Butt Connectors

Butt connectors join two wires end-to-end. They fix or extend wires. Crimp them for a strong connection, keeping the circuit working.

Materials and Construction

Car connector materials give different benefits:

Plastic Connectors

Plastic ones keep out moisture and dust. They are light and don't rust, good for many car places.

Metal Connectors

Metal ones conduct electricity well and last long. They handle heat and stress, great for engine areas.

Connector Functions

Car connector types do different jobs:

Power Connectors

Power ones give power to parts like headlights. They handle high currents needed by devices.

Signal Connectors

Signal ones send data between modules. Important for things like infotainment systems.

Ground Connectors

Ground ones return electrical current safely, stopping voltage spikes.

Knowing these helps you pick the right connector when fixing cars so they stay safe and work well.

Steps to Find Connector Types

Finding the right car connectors keeps your car working well. Follow these steps to know which connector you need.

Look Closely

Start by looking at the connector. This helps you learn about it.

Shape and Size

Check the shape and size of the connector. Car connectors can be rectangle, circle, or square. Measure it to find a match. This stops wrong connections that might break things.

Color Codes

Notice the colors on the connector. Many car connectors use colors to show what they do. Red might mean power; black could mean ground. Knowing these colors helps you know its job fast.

Use Manuals and Guides

Look at guides to check your guess. They give details about car connectors.

Maker's Manual

Read the maker’s manual for your car. It has pictures and info about all connectors in your car. This helps you pick the right one.

Online Help

Look online for more help. Websites and forums about fixing cars have lists of connectors. Search by your car’s make and model to find what you need.

Use Tools for Finding Connectors

Use tools made for finding out about car connectors types. These tools give exact sizes and info.

Multimeters

Use a multimeter to check how electricity flows in the connector. It checks voltage, resistance, and if current can pass through it. This tells you if it works like it should with new parts.

Connector Kits

Think about using a kit for finding connectors. These kits have tools and guides to help find them right away. They often have sample pieces so you can compare them with yours directly.

By doing these steps, you'll know which car connector is right for replacing old ones, keeping your car safe.

When you change car connectors, follow good steps. This helps make sure they work well and safely.

Be Safe

Safety is most important with car connectors.

Turn Off Power

First, turn off the power. This stops shocks and keeps you safe. Always unhook the car battery to stop any electricity flow.

Use Right Tools

Use the right tools for the job. Good tools keep connectors and wires safe. Use wire cutters, crimpers, and pliers for handling car connectors well.

Pick Correct Replacement

Choosing the right connector keeps your car's system working well.

Check Fit

Make sure new connector fits like old one. Look at pins, shape, and size. A good fit makes sure it works in your car.

Choose Quality

Pick strong connectors that last long. Good ones handle tough conditions better. Quality saves time and money later by not breaking soon.

Install Rightly

Proper install makes sure connectors do their job right.

Tight Connections

Make all connections tight and secure. Loose ones can cause problems. Check each one to ensure they're firm in place.

Test New Connector

After putting it in, test it out. Use a meter to check if electricity flows right. Testing shows if it's working properly after install.

By doing these steps, you replace car connectors safely and keep your car's system in top shape.

To find and change car wiring connectors, do these steps:

Look Closely: Check the connector's shape, size, and colors.

Use Guides: Read manuals and online help to know it right.

Try Tools: Use multimeters and kits to check carefully.

Picking the right connector keeps your car's wires working well. Make sure new ones fit and are good quality. Check your wires often for damage. This helps stop problems later and keeps your car safe and running well.

See Also

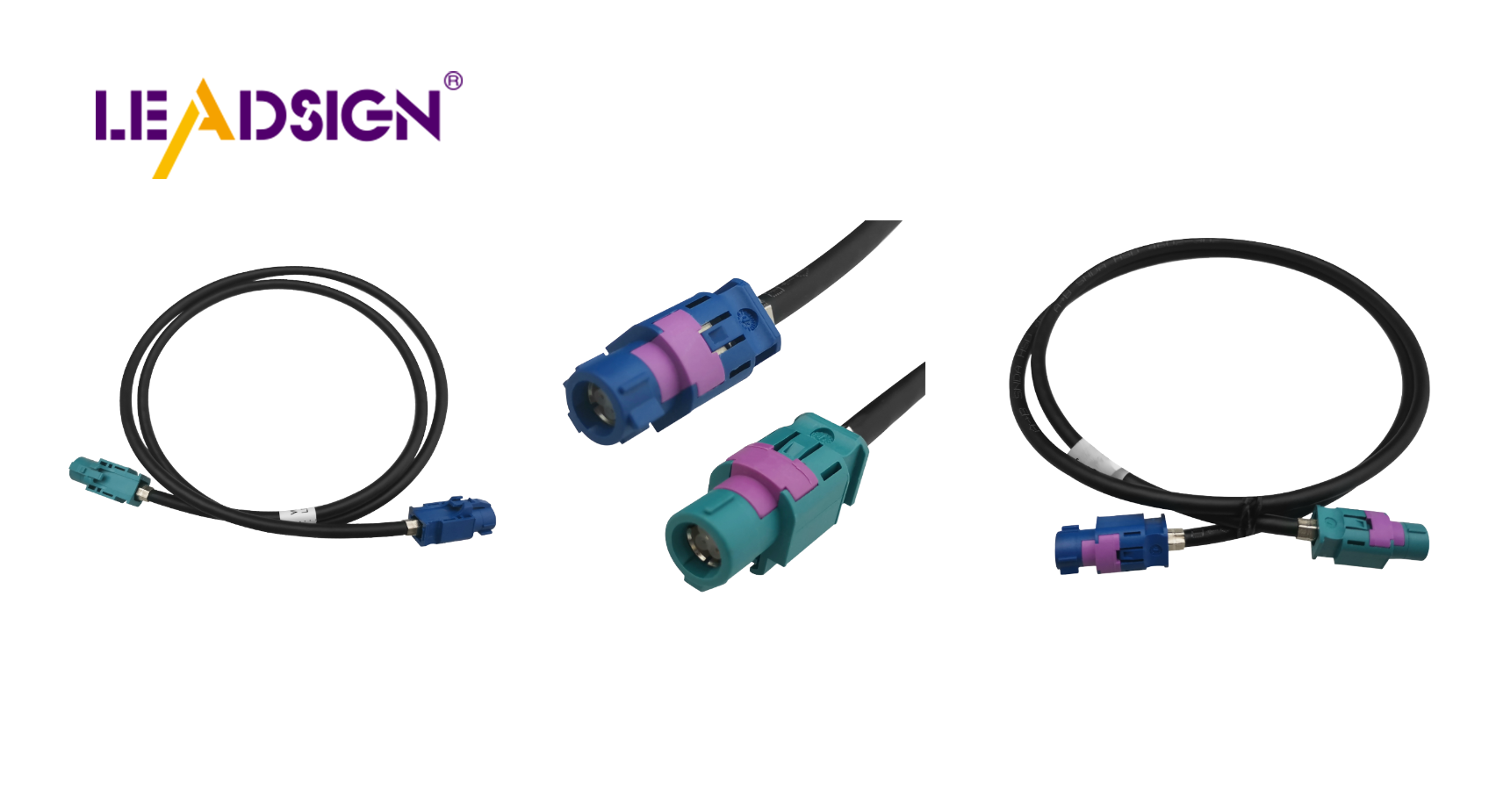

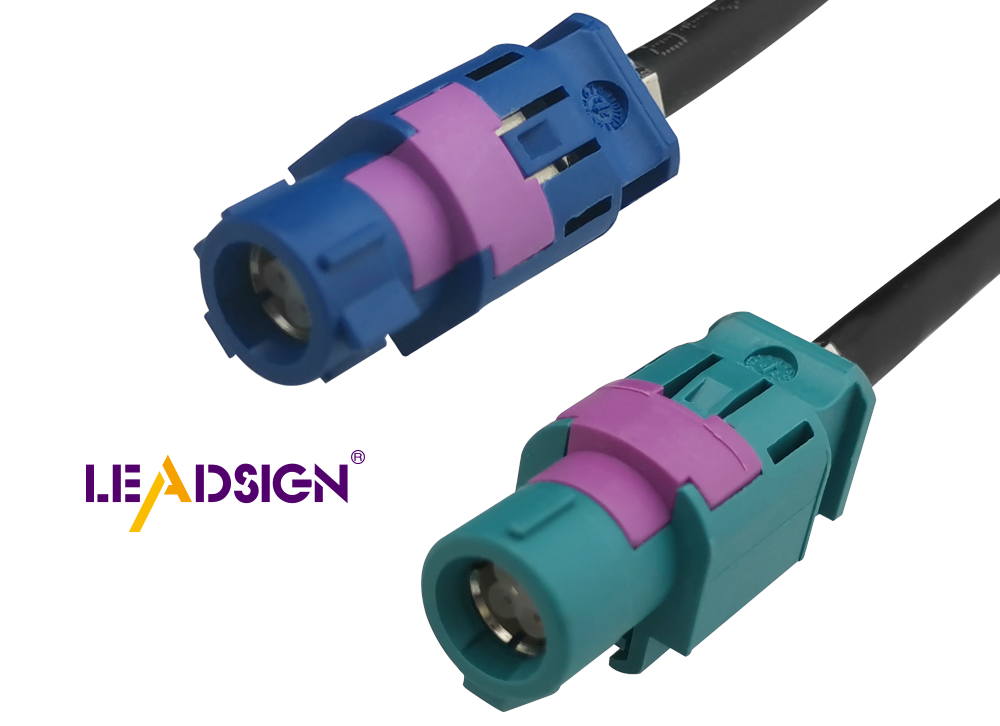

Exploring Ford Fakra Connectors: A Comprehensive Overview

Understanding HSD Connectors in Automotive Sector: The Fundamentals

Significance of Fakra Connectors in Contemporary Automobiles

In-Depth Analysis of HSD Connectors: A Detailed Overview

Significance of FAKRA Connectors in Auto Industry Implementations