How to Identify Automotive Wiring Connector Types for Replacement

Identifying the correct automotive electrical connectors types is crucial for car repairs. Connectors frequently require replacement due to aging or damage. Environmental factors and usage can lead to a higher failure rate compared to standard wires. However, determining the specific type of car connectors can be challenging. It is essential to consider factors such as the number of pins, shape, and color. Selecting an incorrect connector can result in issues, so it is important to exercise caution and precision during the selection process.

Learning About Car Electrical Connectors

When fixing cars, knowing about different electrical connectors is important. These connectors help car parts talk to each other. Let's look at the types, materials, and uses of these connectors.

Types of Car Electrical Connectors

Car electrical connectors have different shapes and jobs:

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They are easy to use and reliable. You see them in fuse boxes and other systems.

Pin Connectors

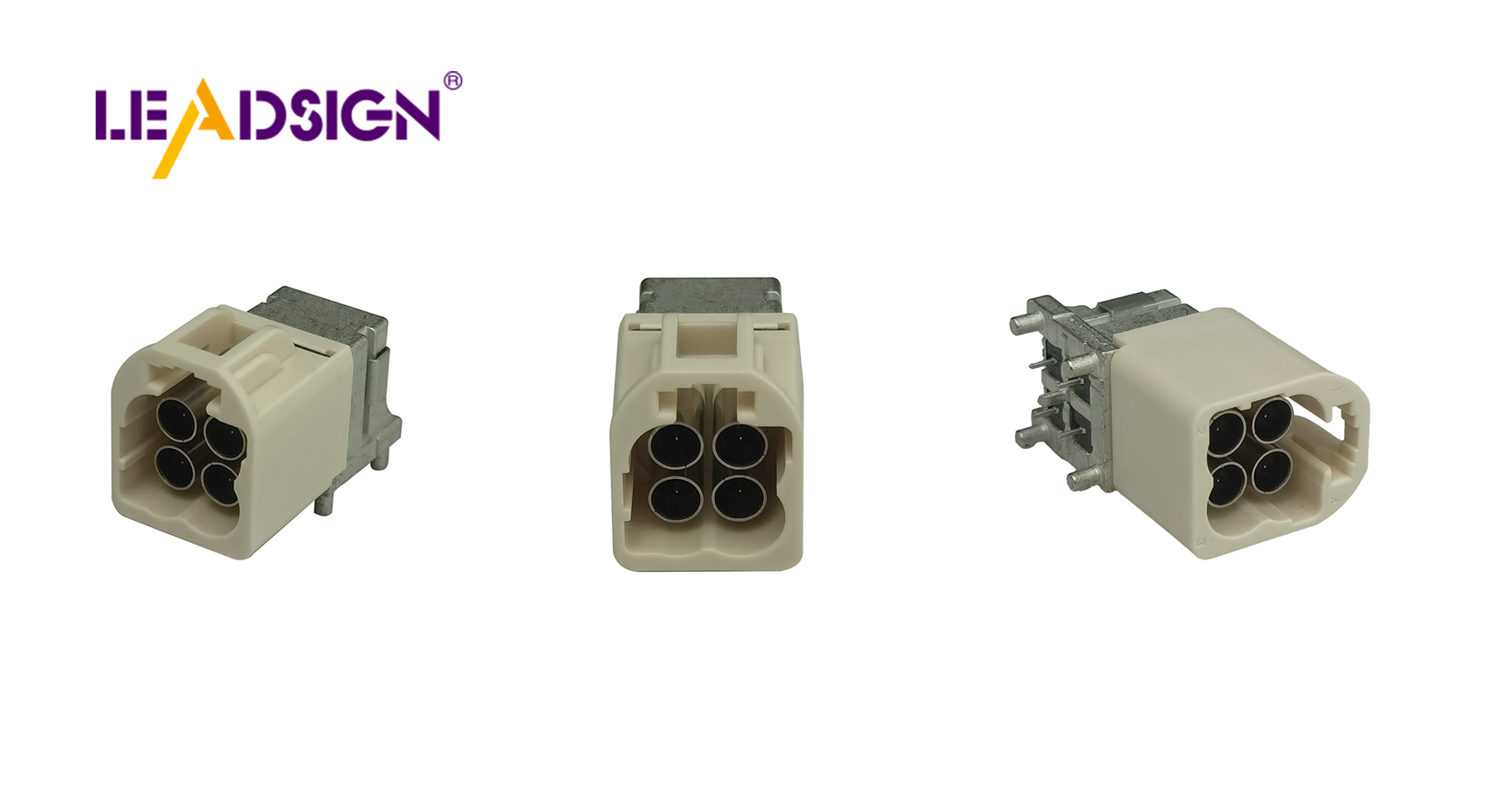

Pin connectors have pins that go into sockets. They work in many car systems like sensors and controls.

Bullet Connectors

Bullet connectors are round for quick connections. They're used in lights where you might unplug often.

Butt Connectors

Butt connectors join two wires end-to-end. They're good for fixing or changing car wires.

Connector Materials

The material affects how a connector works:

Plastic Connectors

Plastic ones are light and don't rust. They work well where there's water or chemicals.

Metal Connectors

Metal ones are strong and conduct electricity well. They're used in hot or shaky places like engines.

Connector Uses

Connectors are key in many car parts:

Engine Wiring

Connectors here send signals and power to engine parts. They handle heat and shaking well.

Lighting Systems

In lights, they power headlights, taillights, and inside lights. They must be tough against water.

Audio Systems

Audio system connectors move sound between radios, speakers, and amps. They need to keep sound clear.

Knowing about these car electrical connectors helps you choose right when fixing them. Picking the right type keeps your car's electric parts working well.

Steps to Find Car Electrical Connectors

Finding car electrical connectors needs a few steps. Each step helps you pick the right connector for your car. Let's look at these steps.

Look Closely

Start by looking closely. This is important to find out which car electrical connector it is.

Shape and Size

Check the shape and size of the connector. Connectors have different shapes and sizes. Blade connectors are flat, bullet ones are round. Pin connectors have pins that fit into holes. By checking these, you can guess which connector you need.

Color Codes

Next, notice color codes. Many car electrical connectors use colors to show their job or match with others. For example, light system connectors might be colored differently from engine ones. Knowing these colors helps you choose the right one.

Use Manuals and Guides

Manuals and guides help find car electrical connectors.

Maker Manuals

Look at maker manuals. These give info about your car's connectors. They often have pictures and details to help match the connector type.

Online Help

Check online help too. Websites about fixing cars often talk about connectors. You can see pictures, read descriptions, and learn from others' experiences to find the right connector.

Use Tools for Identifying

Tools can also help find the right car electrical connector type.

Multimeters

Use a multimeter to check how electricity flows in the connector. It checks voltage, current, and resistance. Compare these with manual details to confirm the type.

Connector Kits

Try using connector kits too. These kits have many connectors and tools to help identify them correctly, especially if you work on many cars.

Connector Experts Team says it's important to pay attention when finding connectors. If unsure, ask a pro for help with choosing the right one for repairs.

By following these steps, you can find car electrical connectors easily. This helps keep your car's electric parts working safely.

Tips for Replacing Connectors

Changing car connectors needs careful work. Follow these steps to do it right.

Matching Correctly

Make sure the new connector fits well. It should be the same type and have the right electrical details.

Find the Right Type

Know which connector you need. There are many types like blade, pin, bullet, and butt connectors. Each one does a special job. For example, blade connectors go in fuse boxes; pin ones are for sensors. Match the new one with the old to keep things working.

Check Electrical Details

Look at how much power it can handle. This means checking voltage and current levels. Using a wrong one might break your car's parts. Always check what the maker says to make sure they match.

Install Properly

Putting them in right helps them last longer. Two ways are crimping and soldering.

Crimping

Crimping squeezes the connector onto a wire tight. Use a tool made for this job. Make sure it's firm so it doesn't come loose.

Soldering

Soldering melts metal to join wires and connectors forever. It helps electricity move well through them. Use a solder iron carefully so nothing gets too hot or damaged.

Test After Changing

Check if everything works after changing connectors by testing two ways: continuity and function tests.

Continuity Test

This checks if electricity flows all through it using a multimeter tool. If it beeps, it's good; if not, fix it again.

Function Test

Turn on what you fixed to see if it works fine now—like lights after changing their connector—to make sure everything is okay.

Connector Experts say testing is very important after changes: "Always test to keep things safe."

By doing these steps, you can change car connectors well so your car stays safe and works right.

Finding the right automotive wiring connector is very important. It keeps your car's electric parts working well. Using the correct one stops expensive fixes. Use good tools and ways to help you.

Pick the Right Connector: This helps your system work better and be lighter.

Ask Experts: If unsure, talk to makers or pros for advice.

Take Care of Your System: Check often and change parts when needed to keep things running well.

By learning these steps, you make better car repairs and stay trusted.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Understanding HSD Connectors in Automotive Sector

Significance of Fakra Connectors in Contemporary Vehicles