How to Identify Automotive Wiring Connector Types for Replacement

Finding the right automotive electrical connectors types is crucial in car repairs. Sometimes, you may need to replace connectors if they break or wear out. With the variety of automotive electrical connectors types available, identifying the correct one can be challenging. Understanding these distinctions is key to selecting the appropriate connector for your vehicle, ensuring optimal performance and safety.

Understanding Automotive Electrical Connectors Types

When fixing cars, knowing the different automotive electrical connectors types is important. Each type has a job to make sure your car's electric parts work right. Let's look at the types of connectors and what they are made from.

Types of Automotive Electrical Connectors

Blade Connectors

Blade connectors are very common automotive electrical connectors types. Many cars use them because they are simple and work well. They have a flat metal piece that fits into a slot. These connectors are good for low power and easy to plug in or out.

Pin Connectors

Pin connectors have round pins that go into matching holes. They can be used in many car parts. They fit tightly and are often used where space is small. Pin connectors help keep electric connections steady in your car.

Bullet Connectors

Bullet connectors look like little bullets for quick and easy plugs. They are often used in car lights and other low-power places. Their shape makes them fit well, so they don’t come loose with movement.

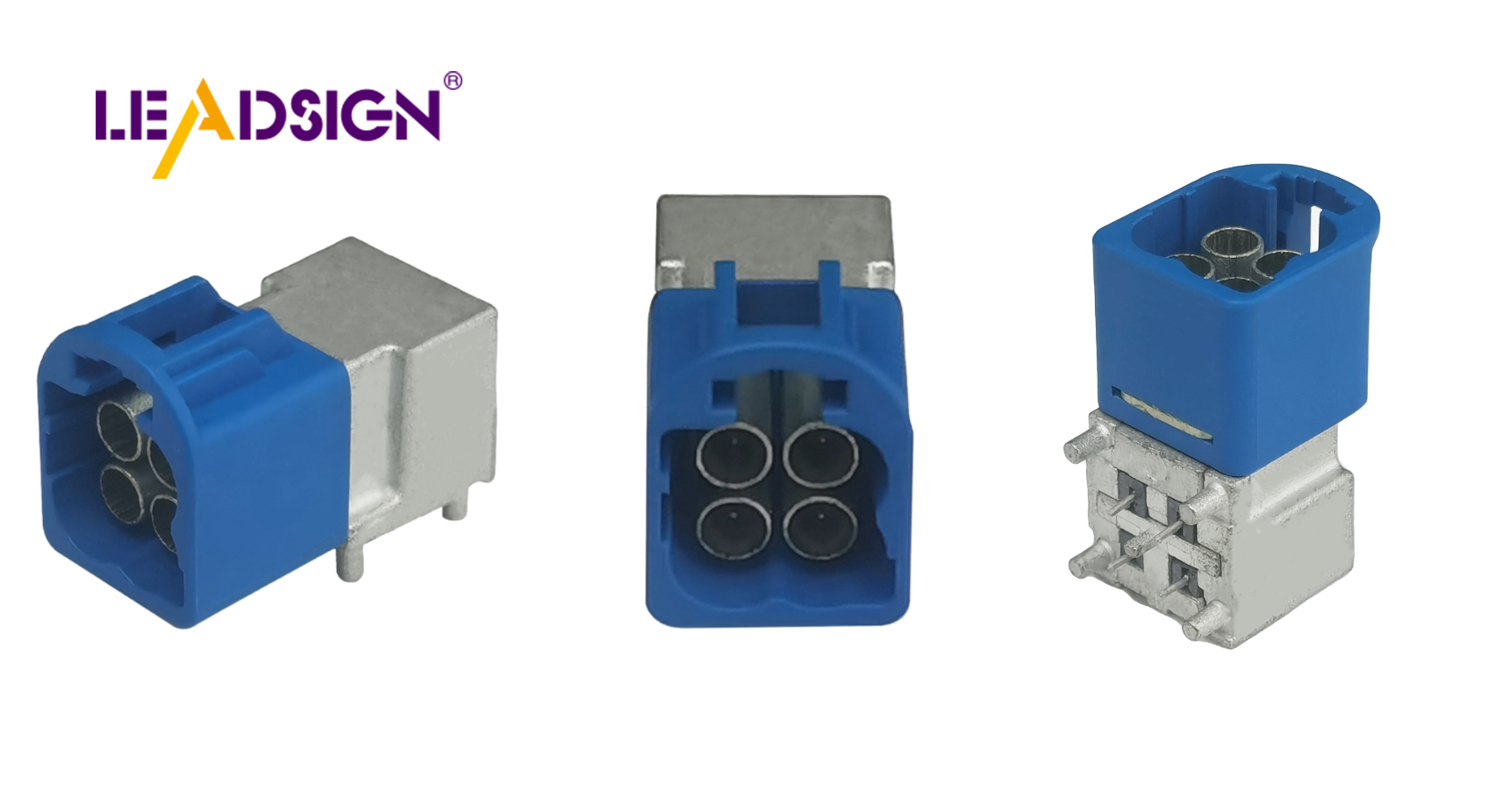

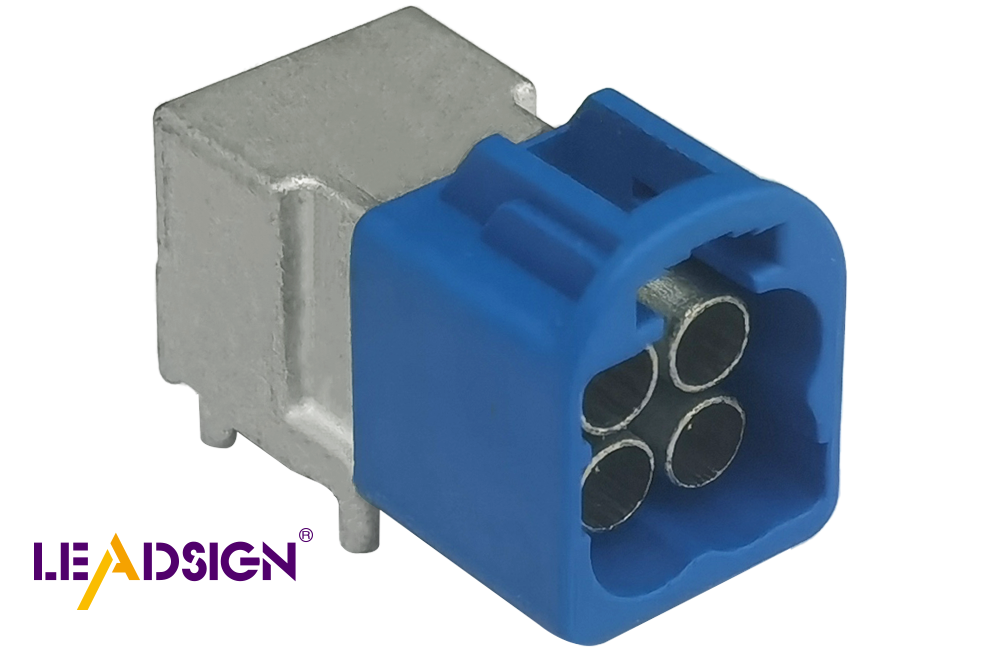

High-Speed Data (HSD) Connectors

High-Speed Data connectors are special automotive electrical connectors types for fast data moving. You find them in cameras, USBs, and entertainment systems in cars. HSD connectors are key for new cars that need digital links.

Connector Materials and Their Importance

What a connector is made from affects how it works and lasts. Different car spots need certain materials based on weather or electric needs.

Plastic Connectors

Plastic ones are light and don't rust easily. They're good when weight matters or not exposed to tough conditions but might not handle heat or shaking as well as metal ones.

Metal Connectors

Metal ones last longer and handle tough spots better like engine areas with more heat or shaking Choosing strong metals means they work well longer.

To pick the right automotive electrical connectors types, think about your car’s brand, model, year, check the manual for details on needed parts Manufacturers give part numbers to make finding matches easier ensuring they fit right.

Steps to Find the Right Connector Type

Finding the right connector is important for your car's electric system. This part will show you how to find the right connector for replacement.

Looking at Connectors

Looking closely is the first step in finding connectors. By checking it, you learn about its features.

Checking Shape and Size

First, look at the shape and size of the connector. Connectors can be rectangles, circles, or squares. Measure them if needed. This helps you choose when looking for a new one.

Noticing Color Codes

Next, check the color codes on it. Many connectors use colors to show what they do or fit with. Colors help match it with a new part. For example, red might mean power; blue could mean data.

Using Tools to Identify Connectors

Besides looking, using tools helps find connectors better.

Using a Multimeter

A multimeter is helpful for finding connectors. It checks voltage and resistance to see if it works right. If it's for a sensor, it checks signals too.

Using Guides

Use guides to help find connectors. They give details like pin setups and uses. They have pictures that make matching easier. Online sites also help find connectors by certain things.

By doing these steps, you can find the right connector type for replacement easily. This keeps your car's electric system working well.

Changing Car Wiring Connectors

Changing car wiring connectors is important. It keeps your car's electric system working well. This part will show you how to get ready and change these connectors step by step.

Getting Ready to Change Connectors

Before you start changing car connectors, you need to get ready. Good prep makes the change easy and safe.

Collecting Needed Tools

First, collect all the tools you need:

Screwdrivers

Wire cutters

Crimping tools

A multimeter for checking

New connectors

Having these tools helps do the job faster without stopping.

Staying Safe

Safety is very important. Before starting, unplug the car battery to stop shocks. Wear gloves and goggles to stay safe from harm. Work in a bright place so you can see well and not make mistakes.

Steps to Change Connectors

After getting ready, follow these steps to change car connectors right.

Taking Out the Old Connector

Find the Connector: Look for the connector that needs changing. Check if it’s rusty or broken.

Take Off the Connector: Use a screwdriver to undo any screws or clips holding it. Pull it apart gently so wires don’t break.

Check Wires: Look at wires for damage. If they are bad, cut them back for fresh wire.

Putting in the New Connector

Get Wires Ready: Use wire cutters to strip wire ends. Leave enough bare wire for a good fit.

Add New Connector: Put stripped wires into new connector slots. Use crimping tool to hold wires tight so they work well.

Test Connection: Use multimeter to test connection works right with no breaks.

Secure Connector: After testing, fix connector with screws or clips in place again. Plug back in battery and check if electric parts work fine now.

By doing these steps, you can change car wiring connectors easily and keep your car’s electric system strong and good.

This guide showed you how to find and change car connectors. You learned why picking the right connector is important for your car's electric system. Using the correct one keeps things safe and working well. If you're unsure, ask an expert for help.

"When you start looking for car connectors, we want it to be a great experience." - FindPigtails

Remember, online guides or apps can help make this easier. Your car's electric health relies on these tiny but important parts.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Understanding HSD Connectors in Automotive Sector: A Primer

Significance of Modern Vehicle Fakra Connectors: An Overview

In-Depth Look at HSD Connectors: A Complete Guide

Significance of FAKRA Connectors in Auto Industry: An Insight