How to Identify Automotive Wiring Connector Types for Replacement

Finding the right automotive electrical connectors types is crucial for your car's performance. You may need to replace connectors that have become old, rusty, or broken to prevent electrical failures. Understanding the different types of automotive electrical connectors helps in selecting the appropriate one for ensuring safety and efficiency. By being able to identify these types, you can effectively address any electrical issues and maintain optimal functionality of your vehicle.

Understanding Automotive Electrical Connectors Types

When working with car electrical systems, knowing the different automotive electrical connectors types is important. These connectors make sure connections stay strong even in tough conditions cars face. Let's look at the types of connectors, what they're made of, and how they're used.

Types of Automotive Electrical Connectors

Blade Connectors Blade connectors are flat metal pieces that fit into slots. They are often used in cars because they are easy to use and hold well. You find them where quick disconnection is needed.

Bullet Connectors Bullet connectors have a round male end that fits into a female socket. They work well for places needing a secure but easy-to-remove connection, like lights.

Pin Connectors Pin connectors have pins that fit into sockets. They're used when many wires connect at once, offering a neat solution.

Butt Connectors Butt connectors link two wires together end-to-end. They're used to join wires securely and keep them insulated, which is key for keeping the electrical system safe.

Materials and Construction

Plastic Connectors Plastic connectors are light and don't rust easily. They're used where there's moisture risk, as plastic covers protect metal parts inside.

Metal Connectors Metal connectors are strong and last long. They're used in hot or shaky places because metal stays connected under stress.

Connector Applications

Engine Compartment In engines, connectors handle heat and shaking well. The right automotive electrical connector here keeps important systems like ignition working.

Interior Wiring Inside the car, wiring connects things like dashboards and climate controls smoothly without taking up much space.

Exterior Lighting Outside lights need waterproof connections to stop water from getting in so headlights and taillights work safely.

Knowing these automotive electrical connector types helps pick the right one for your car's needs whether it's engine work or lighting fixes.

Steps to Find Wiring Connector Types

Finding the right connector is key for your car's electrical system. Follow these steps to pick the correct one.

Look Closely

Start by looking at the connector carefully. This helps you learn about its type.

Check Connector Shape

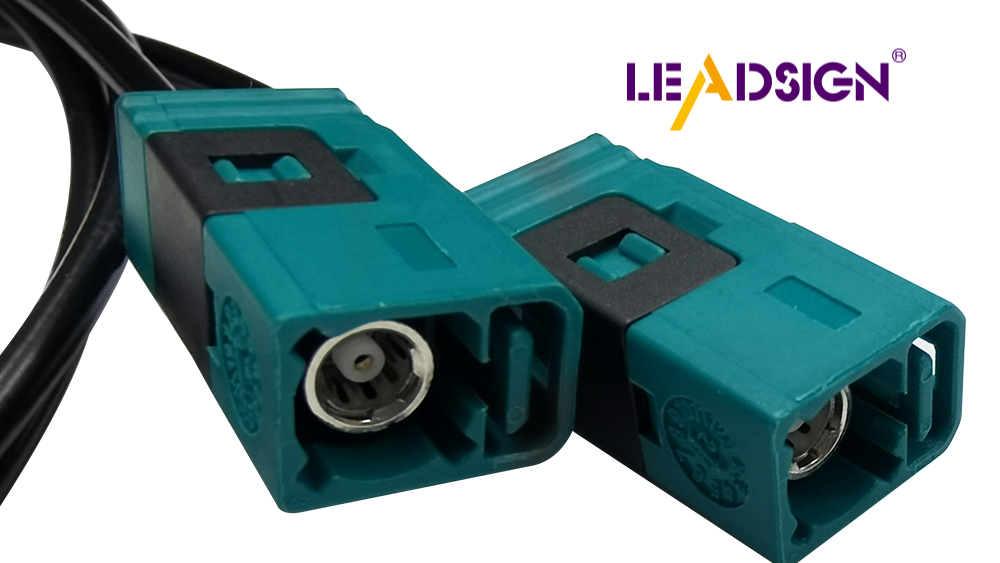

See what shape the connector is. Each type has a special shape. For example, blade connectors are flat, and bullet ones are round. Knowing shapes helps you choose correctly.

Notice Connector Color

Look at the color of the connector. Companies use colors to show different types. The color can tell you what it does and if it fits your car.

Use Your Car Manual

Your car's manual is helpful for finding connectors. It has details just for your car model.

Find Connector Pictures

Look in the manual for pictures of connectors. These show how they look in your car. By matching these with yours, you can tell its type.

Read Connector Details

Check out the details in the manual. It tells about pins, size, and other parts of the connector. Knowing this makes sure you pick one like the old one.

Use Online Help

The internet has lots of info on connectors. Use online sites to learn more.

Join Car Forums

Join forums where people talk about cars. You can ask about connectors and get tips from others who know them well.

Visit Maker Websites

Go to websites of companies that make connectors. They have guides and lists to help find matches by pin count or shape or color.

By doing these steps, you can find out which wiring connector you need to replace correctly.

Replacing car wire connectors needs the right tools and safety steps. Follow these tips to do it well.

To change connectors, you need special tools. These tools help you work safely and fast.

Crimping tools are important for attaching connectors to wires. They make sure wires stay tight. Pick a crimping tool that fits your connector type.

Wire strippers take off wire covers without harm. This tool gets wires ready for new connectors. Choose a stripper that matches your wire size.

Safety is key when fixing car wires. Follow these steps to stay safe.

Always unplug the car battery before working on wires. This stops shocks and short circuits. Take off the negative cable first for safety.

Keep wires tidy and covered to stop short circuits. Use tape or heat shrink tubes on bare wires. This keeps your car's electric parts safe.

After changing a connector, test it to see if it works right. Tests show if your fix is good.

Use a multimeter for a continuity test. It checks if electricity can flow through the path fully. A good test means the connection is tight and works well.

Do a voltage test to check power flow in the connector. Set the multimeter to see voltage levels and read them carefully. Right voltage shows the connection is steady and strong.

By following these tips, you can change car wiring connectors safely and well. Good tools, careful steps, and tests keep your car's electric system working fine.

Finding and changing car wiring connectors is important. It keeps your car's electrical system working well. Knowing the right connector helps keep things safe. It stops problems before they happen. If you're not sure how to do it, ask an expert. They can help you out. Check your car's connectors often for damage. Keep them clean and tight for best results. Doing this makes your car's electrical parts last longer. You'll have a better drive by following these tips.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive: A Primer

Significance of Modern Vehicles' Fakra Automotive Connectors