How to Identify Automotive Wiring Connector Types

Understanding different automotive electrical connectors types is crucial for repairing cars. These connectors play a vital role in ensuring the smooth flow of electricity, which is essential for the proper functioning of various systems in your vehicle. However, selecting the appropriate connector can be challenging due to the variety of types available. It's easy to confuse similar connectors or overlook weather-related considerations. This comprehensive guide simplifies the selection process, helping you make the right choice and prevent errors. Enhance the safety and efficiency of car repairs by familiarizing yourself with the various automotive electrical connectors types.

Understanding Automotive Electrical Connectors Types

Knowing the different automotive electrical connectors types is important for anyone fixing cars. These connectors help electricity flow well, which is key for things like safety and checking systems.

Basic Parts of Wiring Connectors

To pick the right connector, you must know its main parts:

Connector Housing

The housing is the outer part that holds everything inside. It keeps out water and dirt. The material used affects how long it lasts and where it can be used.

Terminal Pins

Terminal pins are metal pieces inside that connect wires. They come in many shapes and sizes based on the type. More pins mean better signal sending.

Locking Mechanisms

Locking parts keep the connector attached firmly. They stop it from coming loose, keeping connections stable. Different connectors use clips or latches to lock.

Common Types of Automotive Electrical Connectors

Many connectors are used in cars. Each has special features and uses:

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They are simple to use and connect well. They're good when you need to disconnect quickly.

Bullet Connectors

Bullet connectors look like small cylinders fitting into sockets. They're often used because they fit tightly and are easy to handle in small spaces.

Butt Connectors

Butt connectors join two wire ends together. They're useful for fixing or extending wires in a car's system.

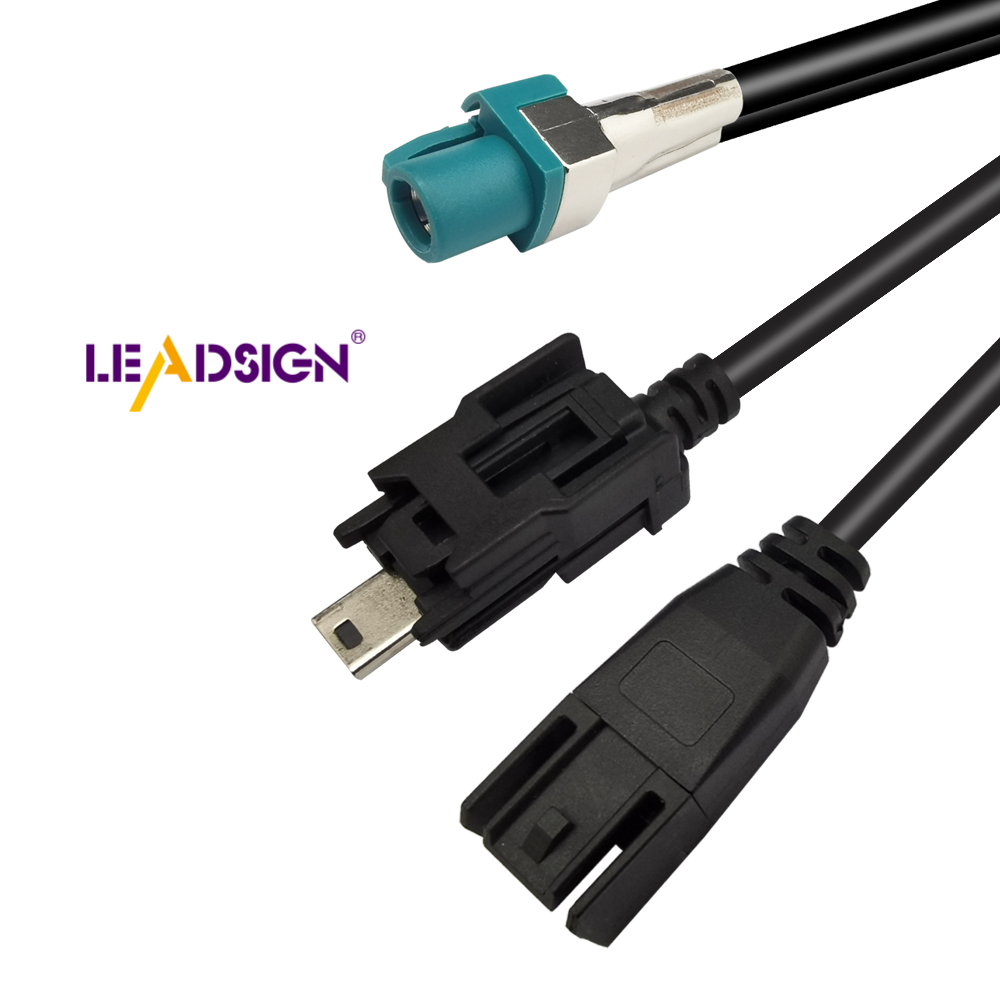

HSD Connectors

HSD Connectors (High-Speed Data) send fast data in car electronics. Used for cameras, USBs, and infotainment systems, they have strong locks and hold cables tight, making them good for tough conditions.

Understanding these parts helps you choose the right connector for your car projects. Knowing these details ensures your car's electrical connections work well.

Steps to Identify Connector Types

Finding the right car connectors can be hard. But, breaking it into steps helps. Follow these steps to pick the correct connector.

Look at It

Start by looking at the connector. This gives you first clues about it.

Check Its Shape

Notice its shape. Car connectors have different shapes like rectangles or circles. The shape shows what kind of connection it is. For example, blade connectors are flat and rectangle-shaped. Knowing shapes helps you choose better.

See Color Codes

Look at colors next. Colors tell what the connector does or fits with. Red might mean power; black could mean ground. Knowing colors stops mistakes and keeps things working right.

Check Its Size

Finally, look at how big it is. Size tells you what it can do or handle. Bigger ones might carry more electricity or work in bigger systems. Compare size with known sizes to find out more.

Use Guides and Books

After looking, use books and guides to check your guess.

Company Books

Company books help a lot. They show details about their stuff, like how it's used and what it's for. Match your connector with what's in the book for sure answers.

Online Help

Online sites are useful too. They have lots of info on car connectors, like pictures and details on fitting parts together well.

Identiconn™ Tool

The Identiconn™ tool is great too! You put in things like pin number or shape, and it finds matches from many types of car connectors for you easily.

By doing these steps, you can find the right car connectors confidently! This makes sure your car's electric parts work safely and well.

Helpful Tips for Finding the Right Connector

Finding the right car connectors is important. It keeps your car's electrical parts safe and working well. Here are some tips to help you find the right ones.

Tools You Need

Having good tools helps you find connectors easily. Here are some tools you should have:

Multimeters

A multimeter checks electricity levels. It tests if connections work right by measuring voltage and current. Use it to see if a connector fits your needs.

Pin Removal Tools

These tools take out pins without breaking them. They come in different sizes for different connectors. Using these tools stops damage and helps put things back together safely.

Crimping Tools

Crimping tools join wires to terminals tightly. They make sure connections stay strong even when shaken or wet. Pick one that matches your connector type for best results.

Mistakes to Avoid

Avoiding mistakes saves time and stops problems in your car's electric system. Watch out for these:

Mixing Up Connectors

Some connectors look alike but do different jobs. Check details like pin number, shape, and size carefully to avoid wrong connections.

Skipping Instructions

Manufacturers give rules on how to use their connectors. Not following them can cause bad setups and issues later on. Always read instructions for best fit and function.

Ignoring Weather Effects

Weather like heat or rain affects connectors' work. Choose ones made for those conditions, like engine areas needing heat-resistant types.

Rob Iversrud, from Waytek, says knowing how connectors lock and hold cables is key in tough spots.

By using these tips and avoiding mistakes, you can pick the right car connectors easily! This makes sure your car's electric parts work safely and well.

To find car wiring connectors, do these steps: look at the connector, use books and guides, and have the right tools. Practice often to get better and feel sure. Knowing them well keeps your car's electric parts safe and working right. It helps with safety and doing things well. By learning these skills, you help your car last longer and work better. Keep learning about different connectors. Your hard work will lead to good fixes and knowing more about car electronics.

See Also

Understanding Automotive HSD Connector Fundamentals

Navigating Ford's Fakra Connector System

Significance of Modern Vehicle Fakra Connectors