How to Identify Automotive Wire Connectors Types for Replacement

Finding the right automotive wire connectors types is crucial for your car. You may need new connectors if old ones break. Broken lights or bad sensors are common issues. These problems often require specific connector replacements. There are various automotive wire connectors types available. Each type serves a unique purpose. Understanding these types helps you select the appropriate one, ensuring your car functions properly and safely.

Understanding Automotive Wire Connectors Types

Knowing different wire connectors is important for cars. Each type has a job to keep the car's electric system working well. Let's look at some connector types you might see.

Basic Types of Automotive Wire Connectors

Blade Connectors

Blade connectors are very common in cars. They look flat like a blade. You can slide them into slots easily. They are used where quick connections are needed, like fuse boxes.

Bullet Connectors

Bullet connectors look like small bullets. They fit tightly into sockets for a secure hold. These are often found in car lights and are easy to unplug when changing bulbs.

Butt Connectors

Butt connectors join two wires together. They look like tubes and need crimping to stay connected. Use them to fix or extend wires, as they handle shaking and weather well.

Specialized Automotive Wire Connectors Types

Weatherproof Connectors

Weatherproof connectors keep out water and dirt with seals. Use them where parts get wet, like under the hood, to stop rust or shorts.

High-Temperature Connectors

High-temperature connectors resist heat without melting. They're important near engines where it's hot, keeping connections safe.

Connector Materials and Their Importance

Plastic vs. Metal Connectors

Plastic ones don't rust and are light but metal ones last longer and conduct better. Pick based on what your project needs most.

Insulated vs. Non-Insulated Connectors

Insulated ones have covers to stop shocks if touching metal parts is possible. Non-insulated ones save space when extra covering isn't needed.

Knowing these connector types helps you choose right when fixing your car's electric system, ensuring it works safely and well.

Tools and Ways to Find Connectors

Finding the right car wire connectors is easier with good tools. Let's learn some ways to find the right connector for your job.

Using a Multimeter

A multimeter checks if wires work well. It helps make sure connectors are okay.

Checking Continuity

To check continuity, set your multimeter to beep mode. Touch both ends of the connector with probes. If it beeps, the connection is fine. This shows electricity moves through without stopping.

Checking Resistance

Resistance checking finds bad connectors. Set your multimeter to resistance mode. Put probes on both ends of the connector. Low numbers mean a good connection. High numbers mean trouble, maybe rust or damage.

Looking at Connectors

Sometimes just looking can tell you about a connector. Use your eyes to see important details.

Seeing Connector Shapes

Check the shape of the connector: round, square, or rectangle? Each shape has a job. USB connectors are rectangular because they get used a lot and need strength.

Knowing Color Codes

Colors help too. Many connectors have colors showing what they do or their power level. Knowing these colors helps match wires correctly.

By using these tools and ways, you can find the car wire connectors you need easily. Whether using a multimeter or looking closely, these methods help choose right for your car's electric system.

Steps to Change Car Wire Connectors

Changing car wire connectors seems hard, but it's easy with steps. Let's make it simple.

Getting Ready and Staying Safe

Safety is first. Prepare well to stay safe.

Unplugging the Battery

First, unplug the battery. This is very important. It stops shocks or sparks when you work. Find your car's battery negative end. Use a wrench to loosen the nut. Take off the cable and put it aside safely.

Collecting Needed Tools

Next, get all tools ready. Having them saves time and stress. You need wire cutters, crimpers, a multimeter, and new connectors. Keep these close before starting.

Taking Out Old Connector

Now remove the old connector carefully so wires don't break.

Cutting and Peeling Wires

Cut wires linked to the old connector using cutters for clean cuts. Strip half an inch of cover from wire ends to show metal for connecting new parts.

Removing the Connector

After cutting and peeling, take out the old connector gently if stuck; wiggle it free without pulling hard to avoid breaking wires.

Putting in New Connector

With old one gone, add new connector for strong connection.

Crimping Steps

Put stripped wire ends into new connector holes. Use crimper tool tightly so wires stay firm inside without slipping out later on.

Soldering for Strong Links

For extra hold, solder connections by heating iron then adding little solder at joint spot; let cool after done for lasting bond strength over time.

By doing these steps right you can change car wire connectors easily! Practice makes you better at fixing your car's electric system safely!

Learn how to find and change car wire connectors. Use the right tools for an easy job. Always unplug the battery first to stay safe. Get your tools ready and follow each step closely. Practice helps you get better, so try it yourself. With care and focus, you can replace connectors well. Keep your car's wires working great by using these tips. Enjoy fixing!

See Also

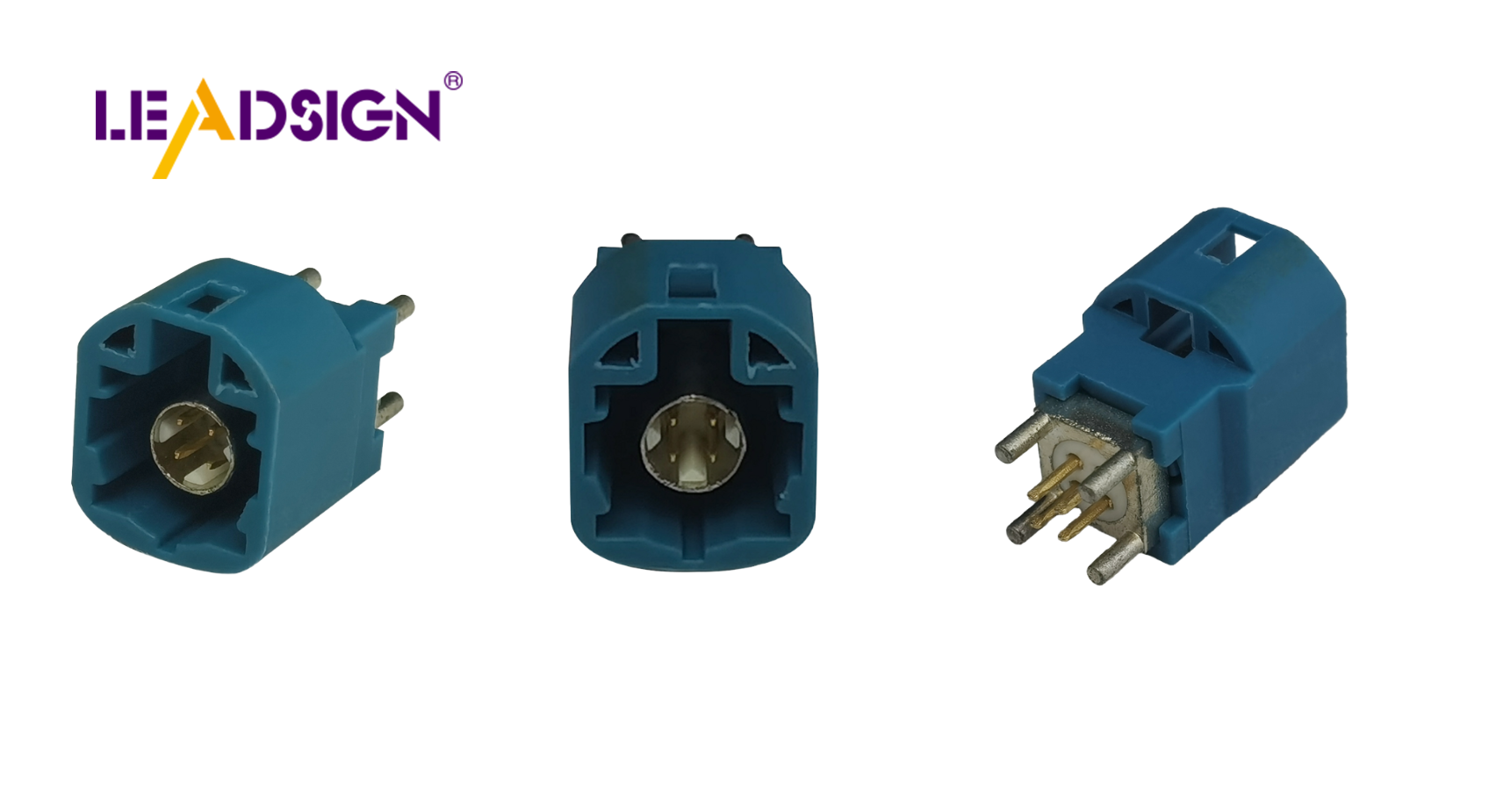

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses