How To Identify Automotive Wire Connectors Types for Easy Replacement

Finding automotive wire connectors types is crucial for repairing vehicles. It allows for quick replacements, saving time and effort. Imagine the inconvenience of using incorrect connectors or faulty replacements. Understanding the specific type makes the repair process straightforward. However, dealing with various shapes and sizes can be challenging. Educating yourself about these automotive wire connectors types simplifies your task, preventing errors. This understanding empowers you to address car wiring issues with confidence.

Understanding Automotive Wire Connectors Types

When fixing cars, knowing wire connectors is important. They come in different shapes and each has a job in the car's wiring.

Types of Automotive Wire Connectors

Blade Connectors

Blade connectors are common. They look flat like a blade. They slide into slots for a strong hold. These are good for quick disconnects, like in car audio and lights.

Bullet Connectors

Bullet connectors are round like bullets. They fit tightly and stay put even if things shake. You see them in lights and power systems.

Butt Connectors

Butt connectors join two wires end-to-end. They're tube-shaped and need crimping to hold tight. Use them to fix or extend wires when you want a strong link.

Materials and Durability

Knowing what materials make up wire connectors helps them last longer.

Plastic vs. Metal

Plastic ones are light and resist rust, good for wet places. Metal ones are stronger and conduct better, great for tough jobs.

Weather Resistance

Some connectors have seals to keep out water and dust, perfect for outside use or engines. Always pick weatherproof ones if they face bad conditions.

By learning about these wire connector types, you can choose wisely when fixing things, whether using blade, bullet, or butt types.

Steps to Identify Car Wire Connectors

Finding car wire connectors can be hard, but it's doable. Follow these easy steps.

Look Closely

First, examine the connector carefully. This helps you find the right type.

Shape and Size

Check its shape and size. Each type has a special shape. Some are flat, others round or tube-like. Measure if needed. Right size means it fits well. Wrong size can cause loose wires or harm.

Color Codes

Look at color codes next. Colors show what they do or match with. Red might mean a certain voltage or use. Knowing colors helps pick the right wire connector type.

Use Guides

If looking doesn't help, don't worry! Other tools can identify wire connectors.

Manuals from Makers

Car manuals have lots of info. They show pictures and details of connectors for cars. Check your car's manual for exact types needed.

Online Help

The internet is useful too! Many sites have info on car wire connectors types. Search by pin count, shape, or color online to check your findings from looking closely.

By using these steps, you can find the right car wire connectors easily. This makes replacing them simple and keeps your car's wiring safe and working well.

Tips for Easy Replacement

Changing car wire connectors is simple with the right tools. Let's see what you need and how to do it well.

Tools Needed

Right tools make the job easy and connections strong.

Crimping Tools

Use crimping tools to hold connectors tight. They press just right for a snug fit. Pick one that matches your connector size. A good crimp stops loose wires and keeps things working.

Wire Strippers

Wire strippers take off wire covers without harm. Choose one that fits your wire size. This gives clean cuts for a good connector fit.

Best Practices

Follow these tips for smooth replacement work.

Proper Fit Check

Make sure the connector fits well. A snug fit stops disconnections. Measure both connector and wire to be sure they match. If loose, try another size. Right fit helps connectors last long.

Test Connections

After changing, test connections by turning on the system. Testing finds mistakes early on. If it fails, check fit and crimp again. This step ensures safe, working connectors.

With these tools and tips, change car wire connectors easily and keep wiring in great shape.

Knowing car wire connectors helps save time and avoid mistakes. You have the skills to replace them easily now. Use what you know to fix your car better and faster. Follow the steps and tips given to make it simple. This keeps your car's wires in good condition. Keep practicing, and soon it will be easy for you to find and change connectors. Enjoy fixing!

See Also

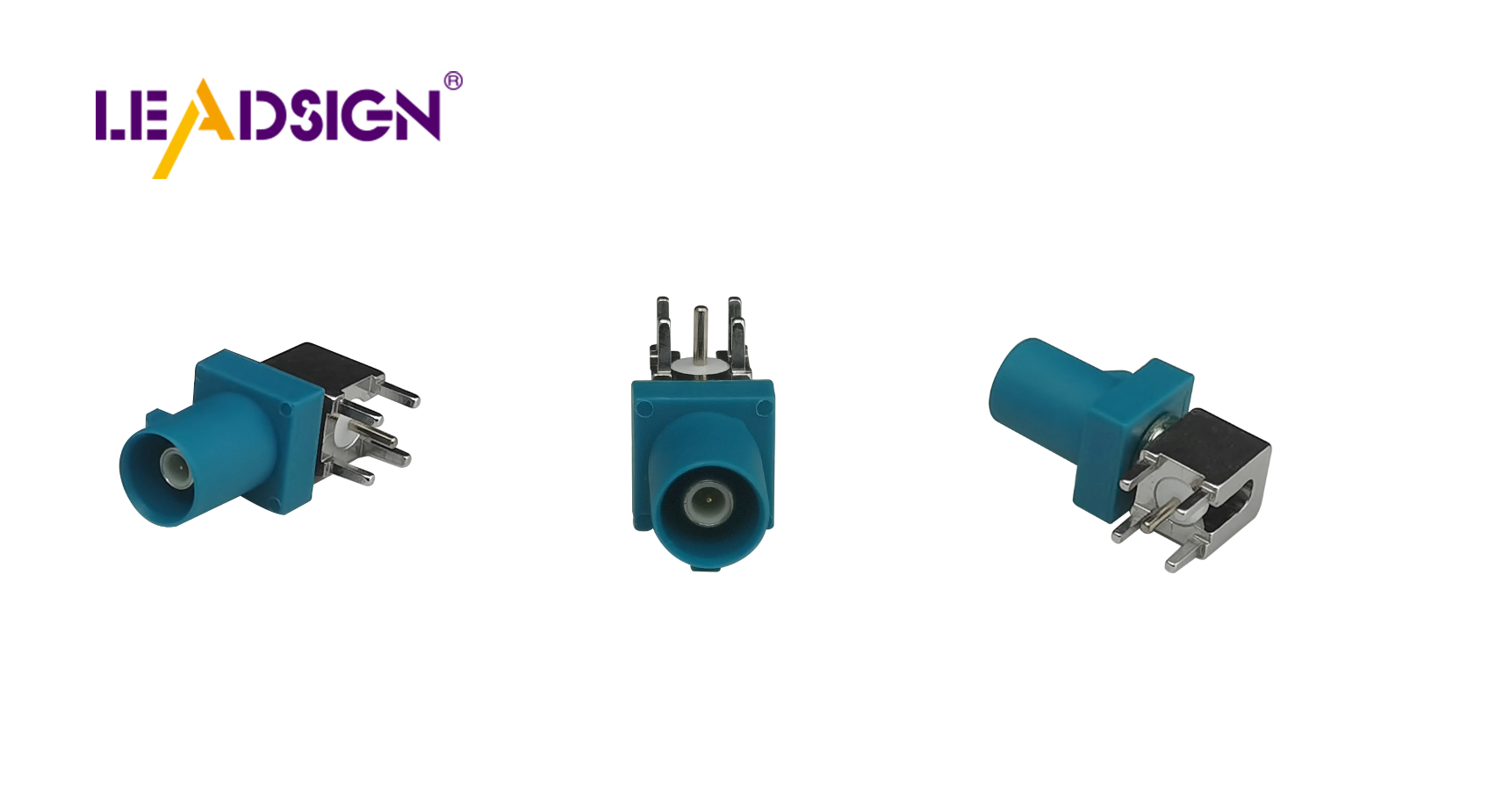

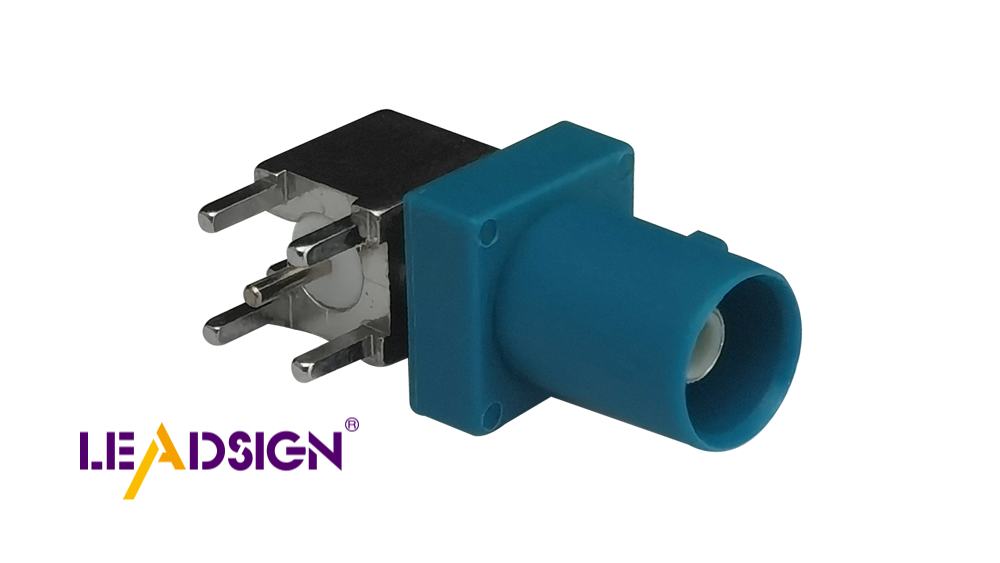

Exploring HSD Connectors in Automotive Sector

Navigating Ford Fakra Connections

Significance of FAKRA in Auto Tech