How to Identify Automotive Electrical Connectors Types for Replacement

Finding the right automotive electrical connectors types is crucial. They play a vital role in maintaining strong connections amidst shaking, rust, and heat in vehicles. If your connectors break or wear out, it's essential to identify the specific automotive electrical connectors types needed for replacement. Understanding the various types of connectors available will enable you to make informed decisions when selecting new ones. These connectors are essential for ensuring the proper functioning and safety of car electrical systems in various conditions.

Understanding Car Electrical Connectors

Knowing car electrical connectors is important. They help the connectors work well and stay connected in different situations.

Main Parts of Connectors

Pins and Sockets

Pins and sockets are key parts of a connector. Pins are like plugs, and sockets are like outlets. They fit together to make a strong connection. Good pins and sockets last long because they don't rust or wear out easily.

Housing and Insulation

Housing covers the pins and sockets, keeping them safe. It stops damage from bumps or hits. Insulation stops electric shorts and keeps out water and dust. Always check housing and insulation when looking at car connectors.

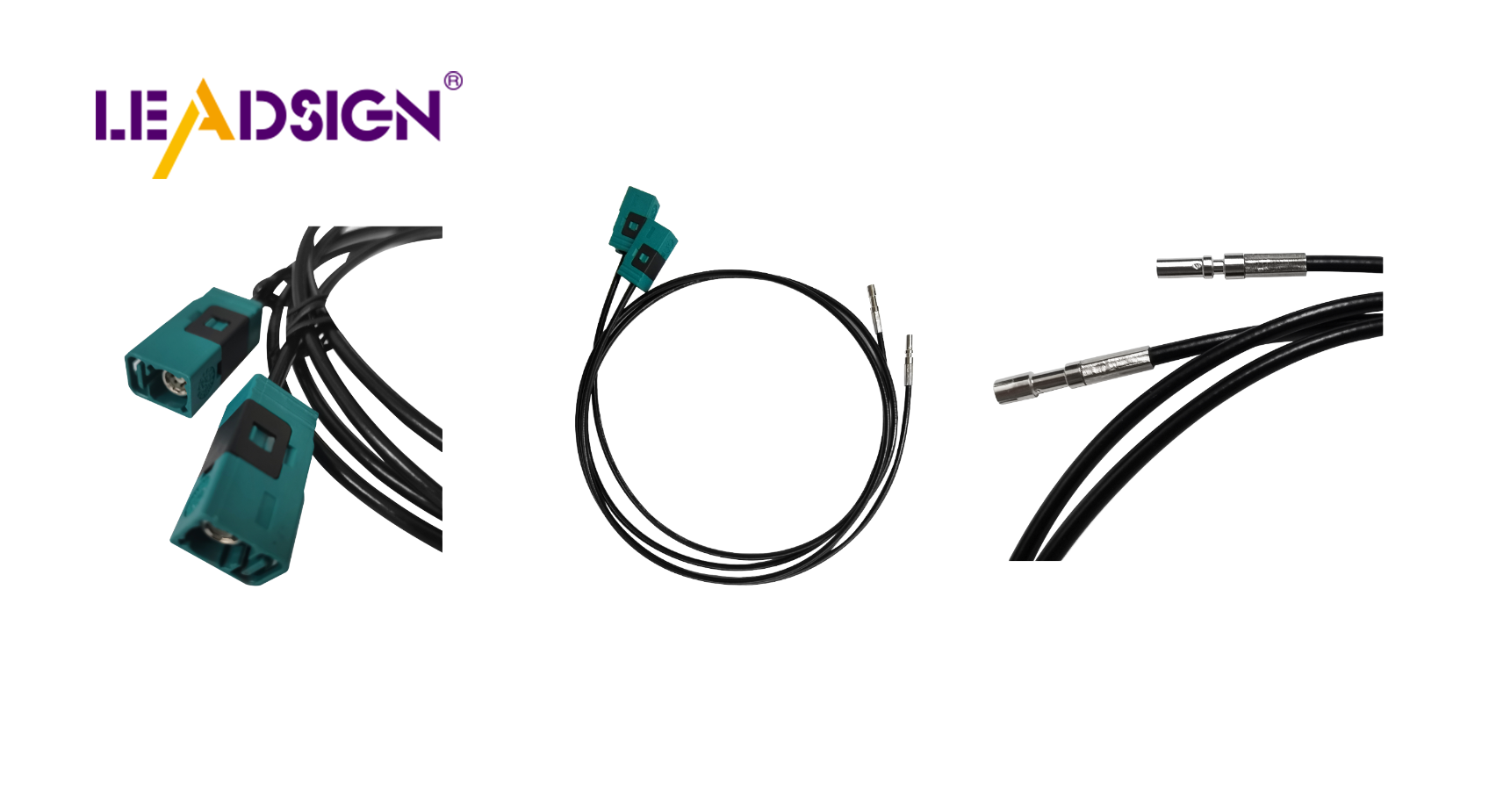

Common Car Connector Types

Knowing different connector types helps you pick the right one.

Blade Connectors

Blade connectors are flat pieces that slide into slots. They are simple to use and work well in cars.

Bullet Connectors

Bullet connectors look like tubes that fit into each other. They're used in car wires because they're easy to connect or disconnect.

Butt Connectors

Butt connectors join two wires end-to-end securely. They're great for fixing car wires.

Connector Materials Matter

Materials in car connectors affect how they work and last.

Metal Types

The metal in pins affects how well electricity flows. Copper is very good, while brass doesn't rust much. Pick metal based on what you need it for.

Plastic and Rubber Insulation

Plastic or rubber cover protects from damage or shorts. Good materials handle heat well, making connectors last longer.

By knowing these parts, you can choose the right car electrical connectors for replacement, ensuring your vehicle's system works reliably.

Finding the Right Connectors for Replacement

Finding the right connectors keeps your car working well. There are ways to find these connectors correctly.

Looking at Connectors

Looking closely helps you see what shape and type they are.

Checking for Damage

Look at connectors for damage signs. See if there are cracks, rust, or color changes. These mean it might be time to change them. Checking often helps stop big problems later.

Noting Shapes and Sizes

Notice the connector's shape and size. Different types have special shapes and sizes. Compare with samples or pictures. This helps you get the right one.

Using Tools to Identify Connectors

Tools help find out more about connector types exactly.

Multimeters and Testers

Use multimeters to check electricity in connectors. They show if a connector works well. Testers can also tell specific types by checking how they work with electricity.

Guides for Connector Types

Look at guides about connector types. These guides give lots of details on different kinds of connectors. They have pictures and facts, making it easy to find a match.

Knowing Connector Details

Knowing details makes sure they fit and work safely.

Voltage and Current Limits

Check how much electricity a connector can take. This tells you how much power it handles safely. Match these with your car's needs for safe use.

Thinking About Conditions

Think about where the connector will be used. Some are made for hot, wet, or shaky places. Pick ones that fit where they'll be in your car.

By doing these things, you can find the right connectors needed for replacement easily. This helps keep your car's system working safely and well.

Steps for Changing Car Electrical Connectors

Changing car electrical connectors needs careful steps. Doing these keeps your car's electric parts safe and working well.

Getting Ready to Change

First, gather tools. You need pliers, a screwdriver, a multimeter, and maybe a heat gun if using heat-shrink tubes. Right tools make it easier.

Safety is important. Turn off the car and take out keys. This stops shocks or short circuits. Wear gloves and goggles for extra safety.

Taking Out Old Connector

Disconnect power first by removing battery cables. This stops electricity flow and keeps you safe.

Next, take out the old connector with pliers or screwdriver carefully. Be gentle to not harm wires or other parts. If stuck, use some force but don't break it.

Putting in New Connector

Match new connector with wires so pins fit right. Good matching stops problems later.

Fix connector in place by tightening screws or fasteners using tools. If using heat-shrink tubing, heat it evenly for tight fit on wires.

Lastly, test connection with multimeter for good work. This checks if new connector works right after change.

By doing these steps, you can change car electrical connectors well, keeping your car's electric system safe and smooth.

Finding and changing car electrical connectors is important. It helps your car work well. You learned about different connector types and parts. Checking them often stops problems like bad wiring. A Jeep Wrangler owner said good connectors matter a lot. Make sure your connectors are in good shape to avoid issues. If unsure, ask an expert for help. One person said, "The connector fit perfectly," showing it's easy when you pick the right ones. Keep your car's electrical system safe and working well.

See Also

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses