How to Identify Automotive Electrical Connectors Types for Replacement

Finding the right automotive electrical connectors types is crucial for maintaining the safety and functionality of your car's electrical components. Faulty connectors can lead to issues such as poor connections or complete malfunctions. It is essential to identify and replace connectors that are old, corroded, or damaged. Utilizing tools like multimeters and connector testers can aid in the replacement process. Mastering the use of these tools will empower you to ensure the strength of your car's electrical system.

Understanding Car Electrical Connectors

Knowing about car electrical connectors is important if you work with car electronics. These connectors help electric signals move smoothly between parts, keeping your car working well.

Main Parts of Electrical Connectors

Pins and Sockets

Pins and sockets are key parts of any connector. The pin, or male part, fits into the socket, or female part. This setup makes sure electricity flows without stopping. When checking car connectors, look at pins and sockets closely. Bent or rusty pins can cause bad connections.

Housing and Insulation

Housing and insulation keep the connector's inside safe. Housing gives support, while insulation stops shorts and protects from things like water and heat. Different connectors use different materials for housing and insulation to last in tough conditions.

Common Car Electrical Connectors

Blade Connectors

Blade connectors are flat rectangles used a lot in cars. They are easy to plug in and out, great for places needing regular checks. You see them in lights and fuse boxes.

Bullet Connectors

Bullet connectors have a round male end that goes into a matching female socket. They’re often used in car wiring because they fit well and are simple to use. They work well in tight spots where other types might not fit.

Butt Connectors

Butt connectors link two wires end-to-end. They're important for fixing or extending wires in cars. Make sure wires are stripped right and crimped tight to avoid problems.

Connector Materials Matter

Metal Types

The metal in car electrical connectors affects how they work. Metals like copper, brass, and aluminum offer different conductivity levels and rust resistance. Picking the right metal helps the connector handle power loads and weather conditions.

Plastic and Rubber Insulation

Plastic and rubber insulate most car connectors. They protect against water, heat, and chemicals. Good insulation keeps connections strong and prevents shorts.

By learning these parts and types, you can better find and replace car electrical connectors, ensuring your vehicle stays reliable.

Identifying Connector Types for Replacement

Finding the right connector is key for your car connectors electric parts. This guide shows ways and tools to help you find car connectors.

Visual Identification Techniques

Shape and Size

Start by looking at the connector's shape and size. They can be rectangular, circular, or square. Measure them to match exactly. Count pins or slots since they differ in connectors.

Color Coding

Color coding helps spot connectors easily. Makers use colors to show different types. Check these colors to pick the right one fast. Remember, colors change with makers, so always check their guides.

Using Connector Catalogs and Guides

Manufacturer Specifications

Check maker specs when finding connectors. These give details on design, materials, and use. By checking these specs, you choose the right part.

Online Resources

Online resources help find connectors too. Many makers have digital catalogs on their sites. These have pictures and info to help you pick correctly. Also, online groups share tips from other car fans.

Tools for Identifying Connectors

Multimeters

A multimeter checks electrical things in connectors. Use it for continuity, resistance, and voltage checks. This tells if a connector works well or needs changing.

Connector Testers

Connector testers are special tools for checking connectors' workability quickly. They spot bad connections or broken wires fastly. Using one ensures your new connector works before putting it in.

"Talking with experts gives great help when identifying tricky connectors." - Car Wire Connector Experts

By using these ways and tools, you can find and change car electrical connectors confidently, keeping your car's electric system strong.

Steps for Changing Car Electrical Connectors

Getting Ready to Change

Collecting Needed Tools

Before changing car connectors, get all tools ready. You need a multimeter, connector tester, wire stripper, and crimping tool. These tools make the job easier. A multimeter checks electricity. A connector tester finds bad connections fast. Wire strippers and crimpers help with wires.

Staying Safe

Safety is very important when working with electricity. Always unplug the car battery first to avoid shocks. Wear goggles and gloves to stay safe from harm. Keep your workspace bright and tidy. Doing this keeps you safe while working.

Taking Out the Old Connector

Cutting Power

First, cut off power by removing the battery's negative end. This stops electricity flow and prevents shocks. Make sure the car is off and keys are out.

Removing the Connector

Find the old connector that needs changing. Take it out by pressing tabs or unscrewing parts carefully. Pull it apart gently without hurting wires. If stuck, use a small screwdriver to help loosen it.

Putting in the New Connector

Aligning Rightly

After removing the old one, get the new connector ready. Match pins or sockets with wires correctly. Push wires into place snugly. Use a crimper to hold them tight.

Checking Connection

Once installed, test if it works right by reconnecting the battery and using a multimeter for checks. It should show steady readings if done well.

By following these steps, you can change car connectors easily and keep your car running smoothly.

Correctly finding and changing car connectors is important for your car's electric system. Practicing these skills makes you better at handling connectors.

"Make sure you can crimp well before starting the job. It's easy, and you'll do it right in a few tries!" - Anonymous User

To keep your car's electric parts working, check connectors often for damage. Use good tools like crimpers and pins to make strong connections. With practice, you'll get good at this and keep your car running well.

See Also

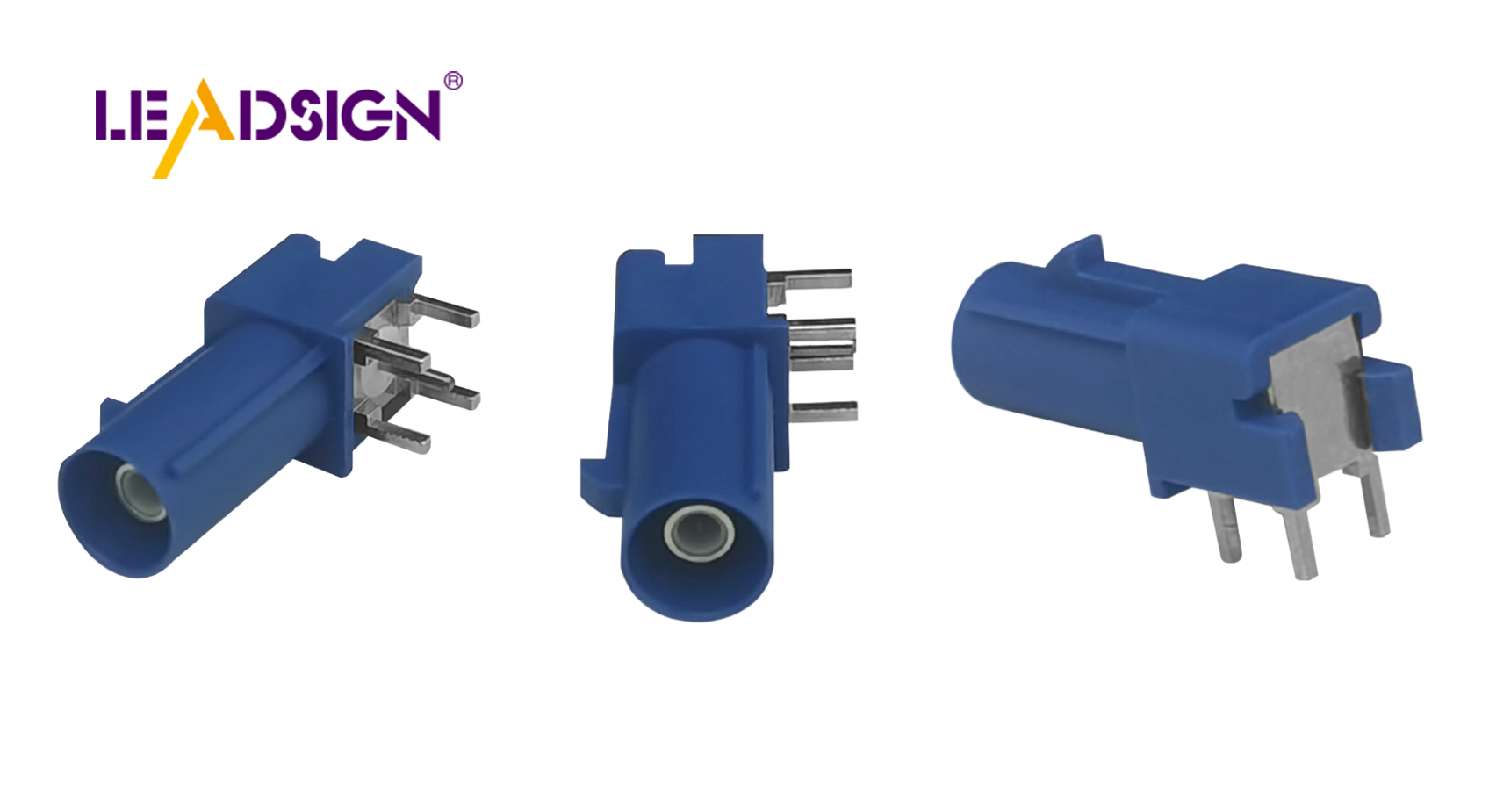

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses