How to Identify Automotive Electrical Connectors Types for Replacement

Finding the right automotive electrical connectors types is important. It helps your car's electrical system work well. Problems like rust, wear, or breakage may need new connectors. To fix these issues, you need simple tools like multimeters and testers. Also, knowing how to look at connectors and understand their setup helps you replace them correctly. By learning these skills, you keep your car's electrical parts lasting longer and working better.

Understanding Automotive Electrical Connectors Types

Knowing about car electrical connectors is important. They help your car's parts work well together.

Basic Parts of Connectors

Car connectors have key parts you should know:

Pins and Terminals

Pins and terminals are the main parts. They carry electricity and keep things connected. Check them for rust or damage to avoid problems.

Housings and Locks

Housings protect pins from water and dust. Locks keep connections tight. Make sure they are in good shape when changing connectors.

Common Car Electrical Connectors Types

Here are some common connector types:

Blade Connectors

Blade connectors are flat and easy to use. You find them in lights and power systems.

Bullet Connectors

Bullet connectors are round. They stay connected even with shaking, often in older cars.

Butt Connectors

Butt connectors join two wires end-to-end. They help fix or change wiring without replacing everything.

Special Connectors

Besides common ones, there are special car connectors for certain needs:

Weatherproof Connectors

Weatherproof connectors stop water and dirt. Use them outside or near engines to prevent rust.

High-Temperature Connectors

High-temperature connectors handle heat well. Use them near engines where it's hot to stay safe.

Knowing these connector types helps you pick the right ones for fixing your car's electrical system.

Finding the Right Connector to Replace

Picking the right car connector is key. It keeps your car working well. There are ways to find the correct connector.

Looking Closely at Connectors

Looking closely helps you spot connectors. By checking them, you learn important details.

Spotting Wear and Damage

First, look for wear and damage signs. Rust or cracks mean a connector needs changing. Bad connectors can hurt your car's work. Regular checks catch problems early.

Knowing Connector by Shape and Size

Next, check shape and size. Each type looks different. Blade connectors are flat; bullet ones are round. Notice these things to pick the right one. Look at its form and pin setup too.

Using Tools to Know Connectors

Tools help find connectors easily and correctly. They give more info than just looking.

Multimeters and Testers

Multimeters check electricity parts. They show if a connector works right. Testing confirms its type fits what’s needed for safety.

Guides for Connector Types

Guides tell about connector types with pictures and words. They help match your connector to the right kind. Experts or makers can help with hard tasks too. Online tools can find connectors by pins, rows, color, or gender.

By mixing close looks with tools and guides, you find the right connector confidently. This way keeps your car’s electric parts strong and good.

Practical Tips for Replacing Connectors

Changing car electrical connectors needs planning and care. Use these tips to do it right.

Getting Ready

Collecting Needed Tools

First, get all the tools you need. Important tools are:

Multimeter: Checks if connections work.

Wire Strippers: Takes off wire covers.

Crimping Tool: Attaches connectors to wires.

Screwdrivers: Loosens or tightens screws.

Heat Gun: Helps with heat-shrink tubes.

Having these ready makes replacing easier.

Staying Safe

Safety is very important with electrical parts. Follow these rules:

Disconnect the Battery: Stops shocks from happening.

Wear Safety Gear: Gloves and goggles keep you safe.

Work in Bright Light: See clearly what you’re doing.

Avoid Water Areas: Water and electricity are dangerous together.

These steps keep you protected while working.

Steps to Replace

Taking Out Old Connector

Find the Connector: Spot the one to change.

Open Locks: Press or slide locks open.

Pull Apart Gently: Separate it carefully from its match.

Look at Wires: Check wires for rust or damage.

Removing old ones gets space ready for new ones.

Putting in New Connector

Get Wires Ready: Strip wire ends if needed.

Connect It Rightly: Match new connector with wires.

Crimp Well: Use tool to attach firmly.

Check Fitment: Make sure it’s secure and lined up.

Good fitting means a strong connection.

Testing New Setup

Making Sure It Works

After putting it in, test the setup:

Reconnect Battery: Bring power back on.

Use Multimeter Again: Check voltage and flow is right.

Turn On System Parts: Ensure everything works fine.

Testing shows if connector is okay.

Fixing Usual Problems

If there’s trouble, try these fixes:

Check Connections Again: Tighten any loose parts.

Look for Damage Signs: Find wear or breaks on parts.

Read Guides Again: Manuals or online help can assist more.

Fixing ensures everything runs smoothly again.

Finding and changing car electrical connectors keeps your car working well. Regular checks stop rust and damage, making parts last longer. One person said getting good connectors for cars like Jeep Wranglers is hard but important. If you have trouble or feel unsure, ask an expert for help. They can guide you and keep your car in great shape, giving you safety and peace on the road.

See Also

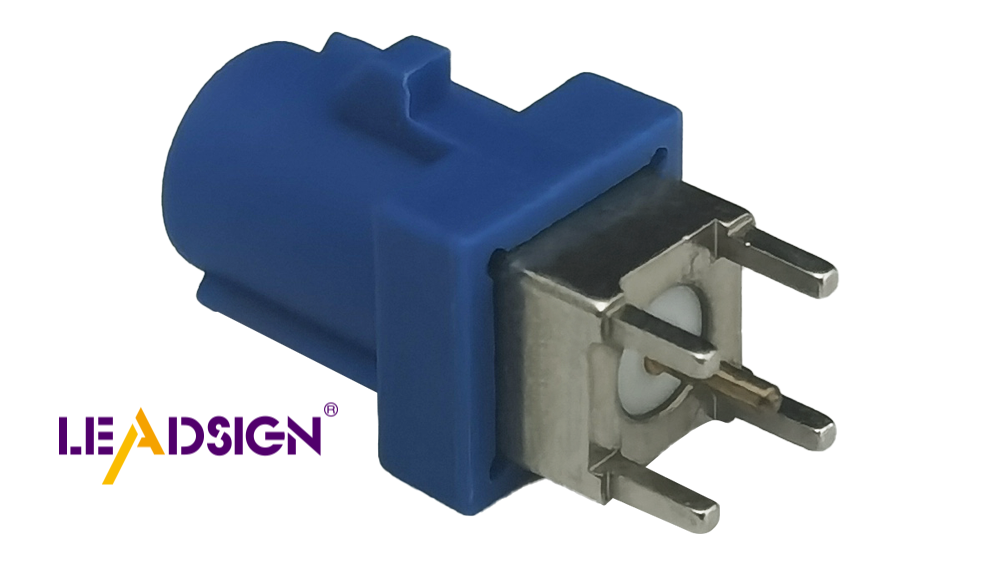

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses