How to Identify Automotive Electrical Connectors Types

Finding automotive electrical connectors types is crucial for automotive work. There are numerous types of connectors, with almost 100 variations found in vehicles. This extensive variety can make it challenging to identify each one. Each type serves a specific function, and understanding the correct type is essential for optimal performance. Selecting the incorrect connector can lead to significant issues or damage. With the increasing complexity of modern vehicles, the number of connectors continues to rise. Therefore, it is vital to have a thorough understanding and knowledge of these components.

Understanding Car Electrical Connectors Types

When you look at car electrical connectors, knowing their parts is key. These parts help the connectors work well in different car systems.

Main Parts of Connectors

Pins and Sockets

Pins and sockets are the main parts of a connector. They make the electric link between vehicle parts. Pins are usually made from metals like brass or copper for good electricity flow. Sockets hold these pins to keep them connected safely. Always check pins and sockets when looking at connectors. Bent or rusty pins can cause bad connections.

Housing and Locking Parts

The housing covers the pins and sockets, giving them insulation and protection. It keeps out things like water, dirt, and heat changes. Most housings use strong plastics like PA66 or PBT because they handle tough conditions well. Locking parts in the housing keep connectors attached firmly. This stops them from coming apart by accident, which could mess up the electric system.

Common Materials Used

Knowing what materials make up car electrical connectors helps you see how strong they are.

Plastic

Plastic is often used for connector covers. It gives great insulation and protection. Plastics like ABS and PC are chosen because they last long without breaking down. They also stay strong under stress, which is important for connectors facing shakes and temperature shifts.

Metal

Metals are mainly for pins and sockets inside connectors. Brass, phosphor bronze, and beryllium copper are common choices. These metals conduct electricity well and resist rusting, keeping connectors working over time even in hard places.

By learning about these parts and materials, you can pick the right car electrical connectors types for your needs better. This knowledge helps with fixing things and makes your car's electric systems work better too.

Identifying Different Car Electrical Connectors Types

Knowing different car electrical connectors makes fixing cars easier. Let's look at some common types and how to spot them.

Blade Connectors

Blade connectors are very popular in cars. They make strong connections easily.

Features and Uses

Blade connectors have flat metal pieces. You see them where quick disconnects are needed, like in fuse boxes or batteries. They are easy to plug in and take out, perfect for places needing lots of checks.

Identification Tips

To find blade connectors, look for flat metal blades. Check their size and shape; they can differ. The cover is usually plastic to protect from weather. Make sure the blade isn't bent or rusty, as this can cause problems.

Pin Connectors

Pin connectors are also important in cars. They give steady connections for many systems.

Features and Uses

Pin connectors have round pins fitting into sockets. They're used in engine controls and sensors, keeping electric flow stable for good car performance.

Identification Tips

Count the pins when spotting pin connectors; it's important. Look at their shape and size to know what they're for. Check for numbers or marks on the cover for more clues. Pins should be straight and clean to work well.

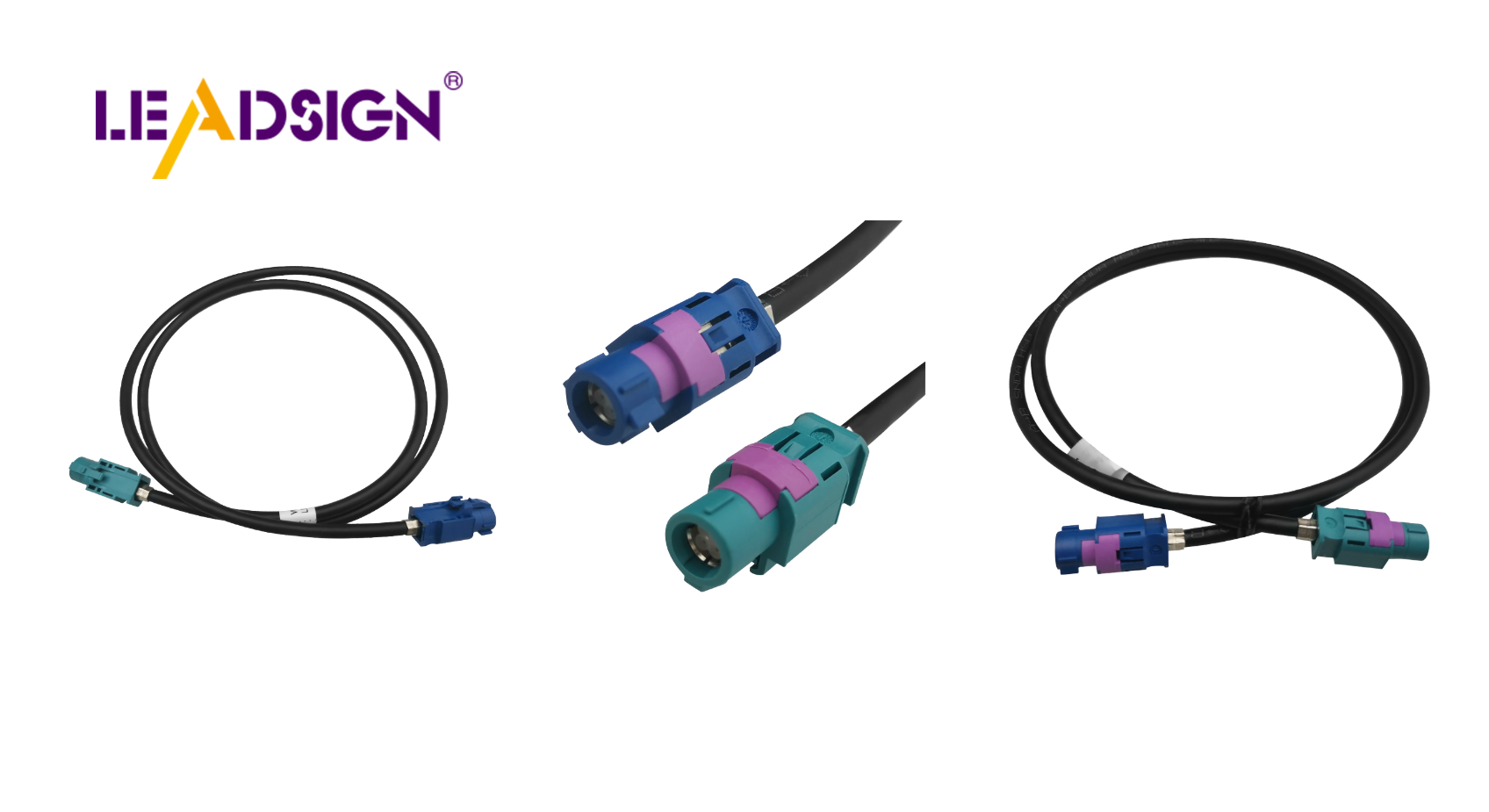

Coaxial Connectors

Coaxial connectors are special car electrical parts used in certain jobs.

Features and Uses

Coaxial connectors carry high signals, found in GPS antennas or radios. They have layers: a center wire, an insulator, and an outer shield to keep signals strong.

Identification Tips

Look for coaxial's layered look with a shiny outer part. Check its size and any marks to match it right with its use. Make sure it's not damaged so signals stay clear.

By learning these connector types, you can fix cars better. Knowing each type's features helps pick the right one so your car's electric parts work well.

Steps to Find Connector Types

Finding car electrical connectors can be hard. But breaking it into steps helps. Let's look at how to do it.

Look Closely

Start by looking at the connector carefully. This step is about using your eyes to find clues.

Check Shape and Size

Look at the connector's shape and size. Is it round or square? Measure if needed. These details help you know the type. Different connectors have different shapes and sizes, so this step is important.

Look at Color and Marks

Next, see the color and any marks. Colors can show what it's for. Look for numbers or letters on it. These often tell you about the type or maker.

Use Maker's Guide

After looking, check some resources. Guides from makers have lots of info.

Use Part Numbers

If there's a part number, use it. Search online or in books from makers. Part numbers show what the connector does.

Compare with Books

No part number? That's okay. Use books to compare what you found. Many online books let you search by shape, size, or color. This step checks your first look results.

Test It Out

Finally, test the connector to make sure it's right. This checks your earlier findings.

Use Multimeters

A multimeter helps here. Use it to check how electricity flows in the connector. This shows if it works as expected.

Do Continuity Tests

Do tests to see if connections are good inside the connector. This checks if electricity moves well through it. If yes, you've found the right type.

By doing these steps, you can find car electrical connectors easily. Keep practicing and soon you'll be great at finding connectors for any job.

To sum it up, here are the main steps to find automotive electrical connectors:

Look Closely: Notice the shape, size, color, and any marks.

Use Guides: Check part numbers and compare with books.

Test Them: Use multimeters and do tests for good connections.

For better results, always check your work twice. Use good sources. Practice often to get better at this skill. The more you handle connectors, the easier it gets to spot them. Keep learning and soon you'll be really good at it!

See Also

Exploring HSD Connectors in Automotive Sector

Navigating Ford Fakra Connectors

Significance of Fakra Connectors in Contemporary Cars