How to Identify Automotive Electrical Connectors Types for Replacement

Finding the right automotive electrical connectors types is crucial for your vehicle. These connectors play a vital role in transmitting signals throughout your car, such as from the engine to the radio. It's essential to replace any cracked or rusty connectors promptly. Be cautious not to apply excessive force, as it can lead to breakage. The electrical systems in cars are intricate, and even a minor connector issue can result in significant problems and impact overall safety.

Understanding Automotive Electrical Connectors Types

Knowing the parts of automotive electrical connectors types is important. Let's learn about the basics and see different kinds you might find.

Basic Parts of Connectors

Every connector has key parts to work well.

Pins and Sockets

Pins and sockets are crucial. They link wires together. Pins fit into sockets, letting electricity pass easily. Keeping them clean and unbroken is vital for a good connection.

Housing and Insulation

The housing covers pins and sockets, shielding them from dust or water. Insulation stops wires from touching each other, preventing shorts. It's usually made of strong plastic or rubber.

Common Automotive Electrical Connectors Types

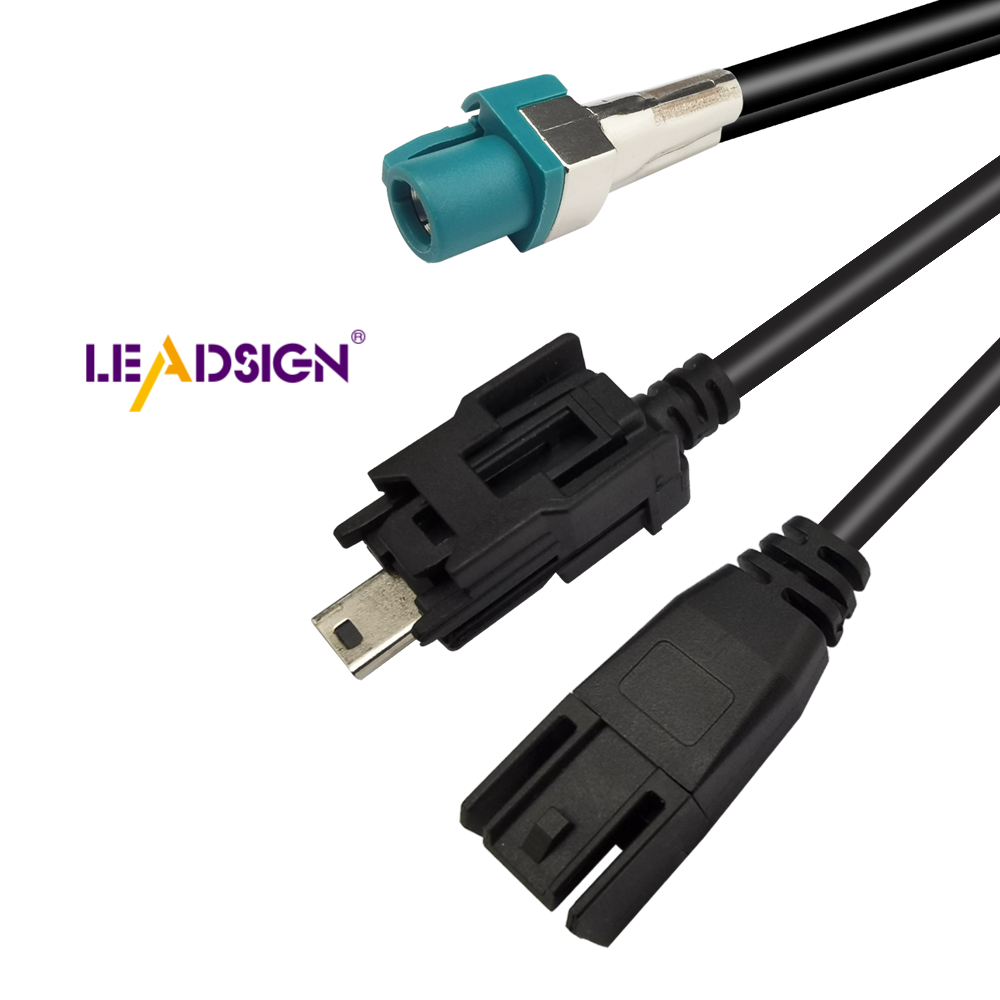

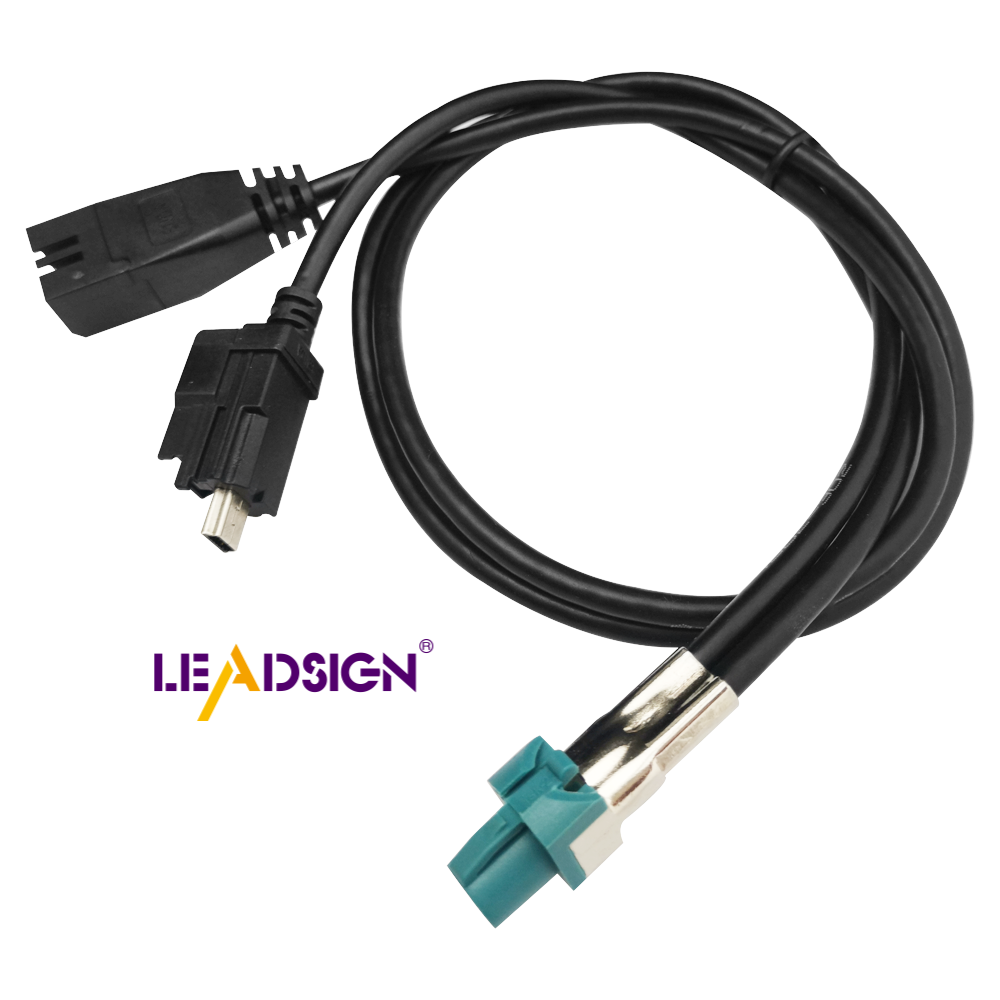

You'll find various connectors in cars, each with a job to do, including HSD Connectors.

You'll find various connectors in cars, each with a job to do.

Blade Connectors

Blade connectors are flat rectangles. They slide into slots to connect. They're common in cars because they're easy to use and dependable.

Bullet Connectors

Bullet connectors look round like bullets. They snap in place securely. They're used where vibrations might loosen others.

Butt Connectors

Butt connectors join two wire ends together. They're great for fixing or extending wires in your car.

Connector Materials Matter

Materials affect how well automotive electrical connectors types work and last.

Metal Types

Connectors use metals like copper or brass for pins/sockets. These metals conduct electricity well and resist rusting, making them last longer.

Plastic and Rubber Insulation

Plastic/rubber insulate well, protecting connections from outside elements. Plastic is light yet strong; rubber adds flexibility against tough conditions.

Knowing these parts helps pick the right automotive electrical connectors types for replacement needs, whether it's Metri-Pack for high performance or Deutsch for heavy-duty tasks.

Steps to Identify Connector Types

Finding the right car connectors is key for your car's electrical system. Let's look at some easy ways to spot these connectors correctly.

Look Closely

First, look closely at the connector. Check its physical features.

Shape and Size

Check the shape and size first. Each type looks different. Blade connectors are flat; bullet ones are round. Compare them to figure it out. Be careful not to bend or break them by using too much force.

Colors and Marks

Next, notice the colors and marks. Many makers use colors to tell their connectors apart. These can help you pick the right one. Look for numbers or letters that show important details.

Use Books and Guides

If looking isn't enough, use books and guides. They have pictures and info on different car connectors.

Maker Details

Check what the maker says about it. These papers have useful info about how it's made and used. They help you see if a connector fits your needs.

Online Help

Online sites can help too. Car part websites have big lists of connectors. You can search by car type to find a match. Forums give extra tips from other car fans.

Tools for Finding Out

Sometimes looking or books aren't enough. Special tools can help find out connector types.

Meters and Testers

Use meters to test electricity in the connector. They check voltage, resistance, and if things connect well, showing if it works right or has problems you can't see.

Kits for Connectors

Think about getting a kit for finding connectors. Kits have tools and guides to help identify them easily with sample parts for comparing.

By doing these steps, you can find the right car connectors confidently so your vehicle stays safe and works well.

Best Ways to Replace Connectors

Changing car electrical connectors can be hard. But, using some good tips makes it simple and safe. Let's see the steps for a good replacement.

Safety First

Safety is most important with car connectors. You don't want surprises when fixing your car.

Turn Off Power

Always turn off power first. This stops shocks or short circuits. Find your car's battery and take off the negative side. This easy step keeps you safe and protects your car.

Right Tools Matter

Use the right tools like pliers, wire cutters, and a meter. These help fix connectors without harm. Don't use wrong tools as they can break things or hurt you.

Pick the Right Connector

Choosing the right connector is key for easy change. Everything should fit well and work fine.

Match Connector Types

Find out which connector you need by looking at shape and size. Compare these with new ones to make sure they match. Wrong types can cause problems or damage your car.

Check Electric Ratings

Look at electric ratings of connectors. They must handle your car's voltage and current well. Wrong ratings can cause heat or failure.

How to Install Well

After picking the right connector, install it correctly for long use.

Tight Connections Are Important

Make sure connections are tight so they don’t fail later. Use pliers to crimp them firmly so they stay put.

Test After Installing

Test new connectors after putting them in place. Use a meter to check if everything works right. Testing finds any early problems fast.

"Change wire connectors if damaged, cracked, burnt, or rusty."

Following these steps makes sure you replace car connectors safely and well. Doing this keeps your car running smoothly without electric troubles later on.

Look at the connector's shape, size, and color. Use books and tools to choose correctly. Replacing connectors right is important for car safety. Ask an expert if you're unsure. It's safer that way. Follow these steps to keep your car working well and avoid problems later on.

See Also

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses