How to Identify Automotive Electrical Connectors Types for Replacement

Identifying different automotive electrical connectors types is crucial for maintaining the functionality and safety of your vehicle. Connectors in cars can deteriorate due to various factors like weather conditions, leading to potential electrical issues. Understanding the types of connectors available enables you to select the appropriate one, preventing further complications. This knowledge not only saves time but also enhances the efficiency of your car's electrical systems, ultimately ensuring a safer driving experience.

Understanding Automotive Electrical Connectors

Knowing car electrical connectors is key for fixing electronics. These connectors are like your car's veins, helping parts talk to each other.

Basic Parts of Connectors

Pins and Sockets

Pins and sockets make up every connector. The pin, or male part, fits into the socket, the female part. This lets electricity flow between circuits. Their size and material change based on use. Big pins handle more power by having a larger contact area for better signal flow. Copper, brass, or bronze are used because they carry electricity well and don’t rust easily.

Housing and Insulation

The housing keeps pins and sockets safe from weather. It makes sure connections stay tight and covered. Insulation stops short circuits and blocks water and dust. Some housings have locks to keep connections steady.

Common Types of Connectors

Blade Connectors

Blade connectors are flat rectangles that fit into slots. They’re simple to use and reliable, so they’re common in cars where quick disconnection is needed.

Bullet Connectors

Bullet connectors look like bullets with their round shape. They hold tight even when things shake around them. They connect easily, which is great for cars.

Butt Connectors

Butt connectors link two wires end-to-end securely by crimping them inside the connector for safety.

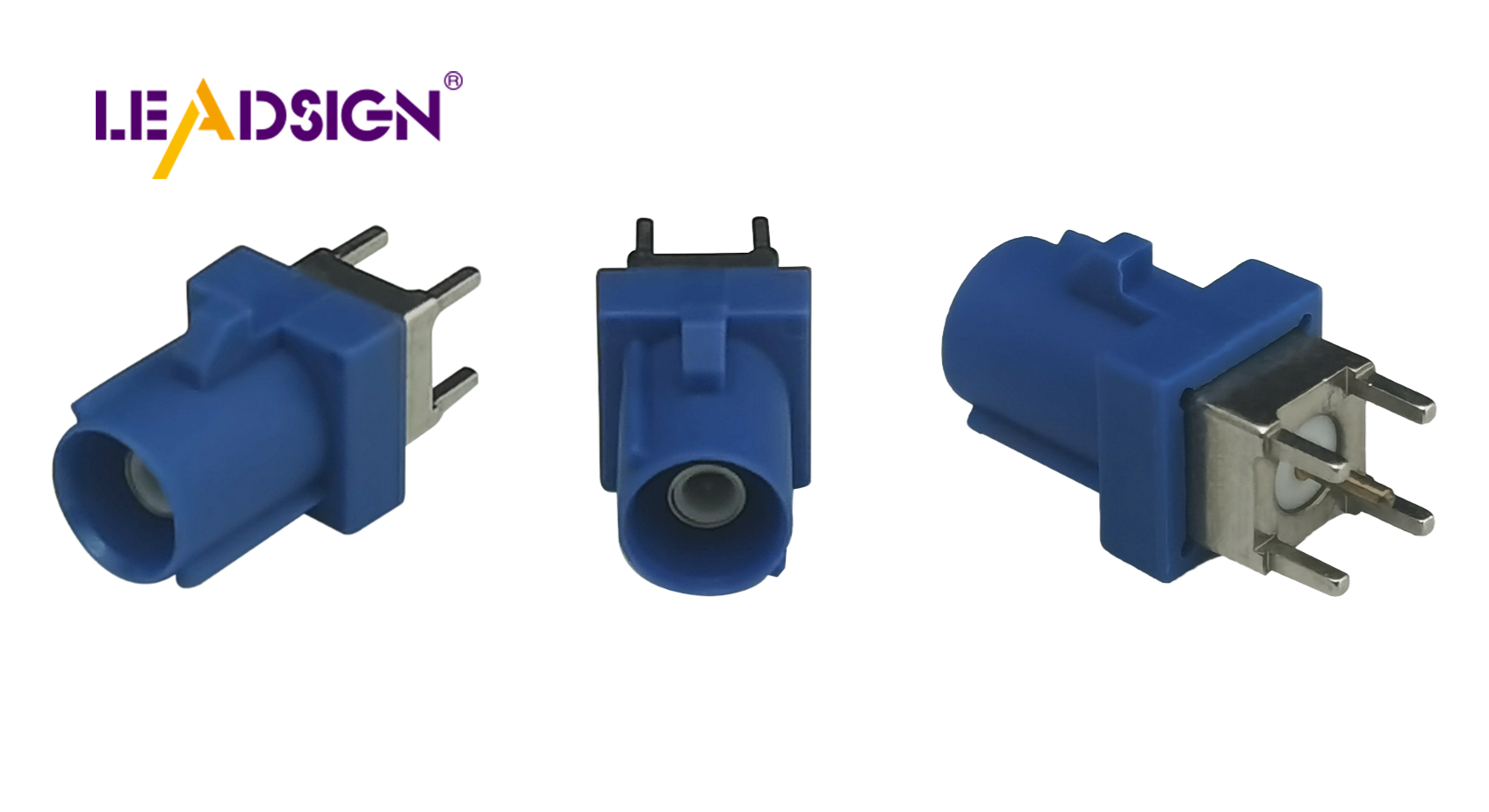

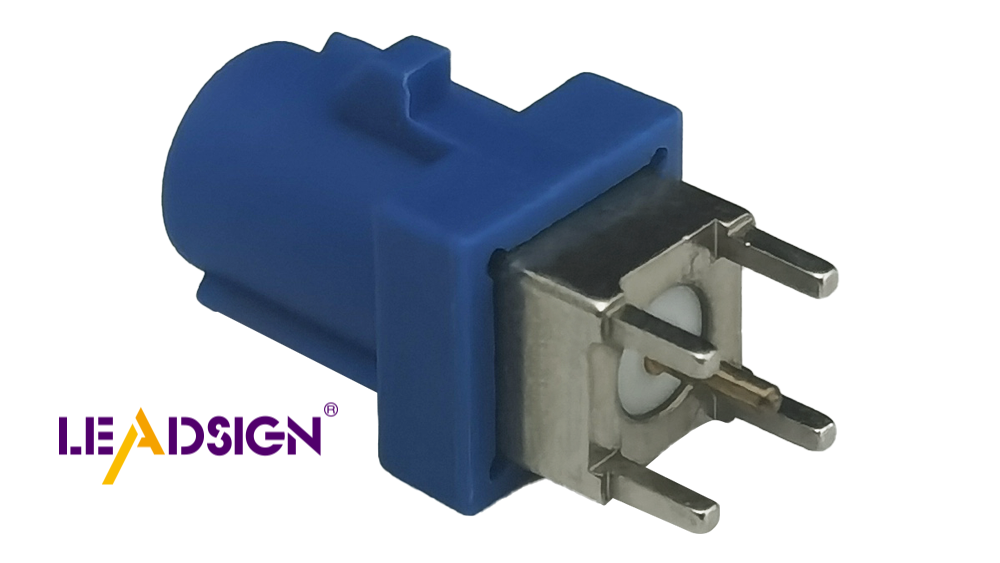

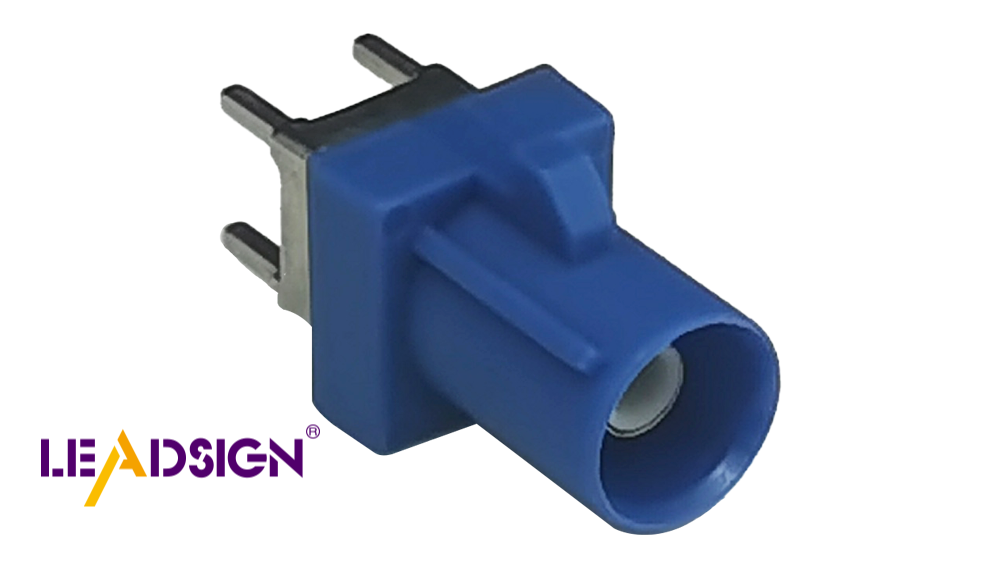

FAKRA Connectors

FAKRA connectors are special for high-frequency uses like GPS or radios in cars. They meet strict rules with secure codes to avoid mistakes. With double locks, they stay put well during assembly.

Knowing these types helps pick the right one for your car’s needs so everything works safely.

Steps to Identify Automotive Electrical Connectors Types

Finding the right automotive electrical connectors needs careful steps. Picking the correct connector is important for your car. This saves time and stops electrical problems.

Look Closely

Looking closely is the first step to find automotive electrical connectors types. By checking it well, you learn a lot.

Find Labels or Marks

Search for labels or marks on the connector. Makers often put these to help know the type. These might be numbers, brand names, or special codes. They help you pick the right one.

Match with Maker's Guide

Match the connector with maker's guide details. You can see these in your car's book or online. Check its shape, size, and color carefully. These things help find the right type.

Test and Check

Testing makes sure you picked the right automotive electrical connectors types. It checks if it works well with your car.

Use Multimeters

Use a multimeter to test it. This tool checks things like voltage and current. It helps see if it works right by finding any issues.

Do Continuity Tests

Do continuity tests to check if electricity flows well through it without stopping. This test finds breaks in connection paths. Passing this test means it's working fine.

Scientific Research Findings: A study shows testing connectors is very important. It links contact resistance changes with failures later on, showing why testing matters for reliability.

By doing these steps, you can find out which automotive electrical connectors types are needed for your car’s safety and efficiency.

When to Change Connectors

Knowing when to change automotive electrical connectors is important. It keeps your car working well and safe. Connectors can get old and cause problems.

Signs of Wear and Damage

Check your connectors often for wear or damage. This helps stop problems before they start.

Corrosion and Rust

Corrosion and rust show connector wear. Water and weather can cause these issues, making electricity flow badly. If you see rust or corrosion, think about changing the connectors. Regular checks help find these signs early, stopping more harm.

Loose Connections

Loose connections mess up electricity flow, causing lights to flicker or gadgets to fail. If a connector is loose, change it fast. A tight fit keeps your car's electric parts working right.

Effect on car performance

Old automotive electrical connectors can hurt how your car works. Knowing this helps you fix connector problems quickly.

Electrical Failures

Bad connectors often cause electric failures like engine misfires or broken accessories. Changing old connectors stops these issues so your car runs smoothly. Fixing them on time avoids electric troubles.

Safety Concerns

Safety worries happen if connectors don't work right. Bad ones can make important systems fail, risking safety for you and others in the car. For example, a bad airbag connector is dangerous in a crash. Changing bad connectors makes sure all safety systems work well.

Research Insight: Studies show testing and fixing worn connectors is key. Knowing wear helps predict life span and avoid surprises.

By watching for wear signs, you keep your car safe and running well. Checking and changing automotive electrical connectors regularly makes sure your car stays reliable on the road.

Finding car electrical connectors needs a few steps. First, look at the connector for any labels or marks. Next, compare it with the maker's details. Use multimeters and do continuity tests to check if it works. Change old connectors on time to avoid safety problems like bad steering or brakes. If you don't know the connector type, ask an expert. This keeps your car safe and working well on the road.

See Also

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses