How to Identify Automotive Electrical Connectors for DIY Projects

Understanding automotive electrical connectors types is crucial for DIY enthusiasts. These connectors are essential to your car's electrical system, ensuring components like lights and radios function properly. However, identifying the correct connector types can be challenging. You may encounter issues such as poor connections or incorrect parts, leading to frustrating failures. This guide simplifies the process, allowing you to address these problems with confidence. By familiarizing yourself with automotive electrical connectors types, you enhance your DIY skills and maintain your car's optimal performance.

Understanding Automotive Electrical Connectors

When doing a DIY car project, knowing different automotive electrical connectors is key. These connectors help your car's electrical system work well. Let's look at the types, materials, and uses of these connectors.

Automotive Electrical Connectors Types

Blade Connectors Blade connectors are very common in cars. They connect wires to things like fuses and relays. Their flat shape makes them easy to use in DIY projects.

Bullet Connectors Bullet connectors have a round shape and hold wires tightly. They are good for parts you often unplug, like lights.

Pin Connectors Pin connectors are used in many ways. They have pins that fit into sockets and are great for complex systems needing many connections.

Connector Materials

Plastic Connectors Plastic connectors are light and don't rust easily. They're used where there's moisture because they last long in cars.

Metal Connectors Metal connectors conduct electricity well and are strong. They're best for high-power parts like starters and alternators because they're tough.

Connector Functions

Power Connectors Power connectors send power to different car parts, like ignition or lights, where steady power is needed.

Signal Connectors Signal connectors move data between car parts, important for systems like ADAS or infotainment for smooth communication.

Ground Connectors Ground connectors let current go back to the battery, keeping the electrical system stable and safe from faults.

Knowing these connector types helps you do DIY projects confidently by ensuring your car's electrical system stays reliable.

Tools You Need

For car DIY projects, having the right tools is key. These tools help you find, check, and change connectors easily. Let's look at the basic and advanced tools you'll need.

Basic Tools

Multimeter A multimeter is very important for anyone doing DIY work. It measures voltage, current, and resistance in automotive electrical connectors. With a multimeter, you can spot problems like short circuits fast. This tool helps keep your car's electrical parts working well.

Wire Strippers Wire strippers are must-haves for dealing with automotive electrical connectors. They let you take off wire coverings without harming the inside part. Good wire stripping means better connections and fewer problems later on. Wire strippers make your work easier and faster.

Advanced Tools

Crimping Tools Crimping tools are needed for strong connections in automotive electrical connectors. They attach terminals to wires tightly so they stay put even when the car shakes or moves a lot. This tool keeps your car's electric system safe and sound.

Connector Removal Tools Connector removal tools make taking out automotive electrical connectors simple without breaking them or the wires around them. Using these tools lets you change connectors safely without hurting other parts nearby.

"Pigtail connectors are unsung heroes in cars." These small parts are crucial for keeping your vehicle running smoothly by linking different electric pieces from lights to data systems.

Having these tools makes working with automotive electrical connectors easier to handle. Whether testing with a multimeter or fixing wires with crimping tools, these items boost your DIY skills and keep your car's electric system reliable.

Steps to Spot Connectors

Finding out what type of automotive electrical connectors you have is important. These steps help keep your car's electric system working well.

Look Closely

First, look at the connectors carefully. This helps you see the different types of automotive electrical connectors.

Check Connector Shape

Notice the connector's shape. Each has its own shape that helps you know it. For example, blade ones are flat and bullet ones are round. Knowing these shapes helps match them with the right part.

Count Connector Pins

Count how many pins are in the connector. More pins usually mean it does more things. Pin connectors have lots of pins for tricky systems. By counting, you learn what each connector does in your car.

Test with Tools

After looking, use tools to test them. This makes sure they work right and stay connected well.

Use a Multimeter

A multimeter is key for testing automotive electrical connectors types. It checks voltage, current, and resistance. With it, find problems like short circuits fast. It shows if connectors work as they should.

Do Continuity Tests

Check if electricity flows through by doing continuity tests. This test makes sure everything works smoothly in the connector. If not smooth, things can break or be unsafe. These tests show if connectors hold up under tough conditions.

Scientific Research Findings: Connectors are vital in electric products but can cause safety issues if not checked right. Testing keeps them strong during shakes and bumps.

By following these steps, you can find and test automotive electrical connectors types easily. This knowledge boosts your DIY skills and keeps your car's electric system steady.

Tips for Successful DIY Projects

Safety Precautions

Staying safe in car projects is very important. Taking safety steps keeps you and your car safe.

Disconnecting Battery

Always take off the battery before any electrical work. This stops shocks and keeps the car's system safe. Remove the negative cable first for a safer space.

Wearing Protective Gear

Wear gear to stay safe from dangers. Gloves keep hands safe from cuts and shocks. Goggles protect eyes from flying bits or sparks. Right gear lowers injury chances.

Common Mistakes to Avoid

Avoid mistakes to save time and avoid stress. Learn from others' errors to improve your skills.

Incorrect Connector Matching

Make sure connectors match right. Wrong ones cause bad connections and failures. Check connector type and pins before use for good performance.

Over-tightening Connectors

Don't tighten connectors too much. Too much force breaks them, causing costly fixes. Tighten just enough to hold without harm, keeping the system strong.

Key Takeaway: Stay focused and follow steps carefully to avoid errors. Distractions lead to mistakes, so keep workspace clear and mind sharp.

Follow these tips for better DIY car projects success. Focus on safety, dodge common errors, and enjoy doing a great job.

You now know about car electrical connectors, tools, and how to find them. This helps you do DIY projects confidently. Use this knowledge to improve your skills and keep your car's electric parts working well. Knowing the right connector is key for safety and good performance. Enjoy using what you've learned for successful DIY projects.

See Also

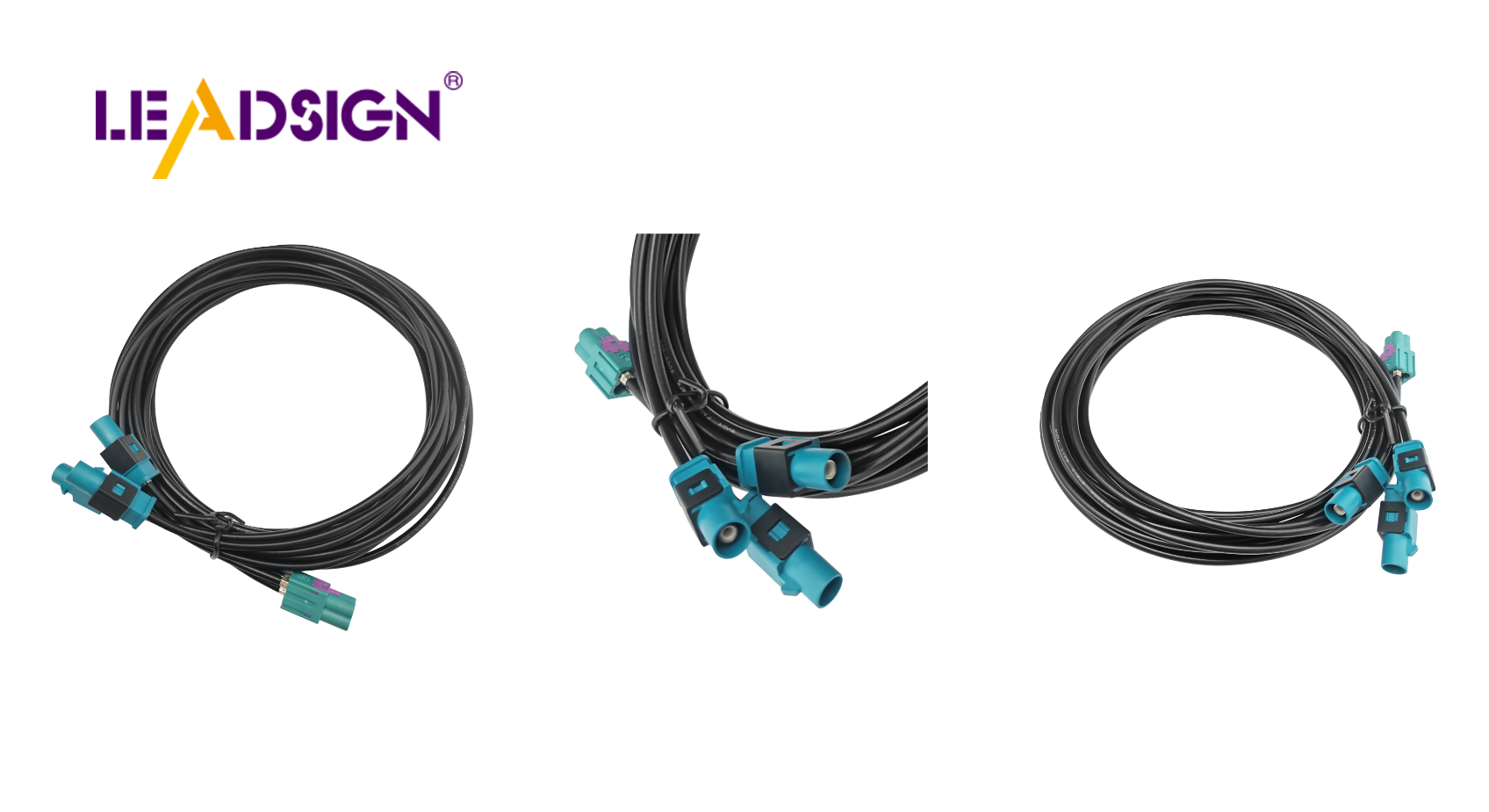

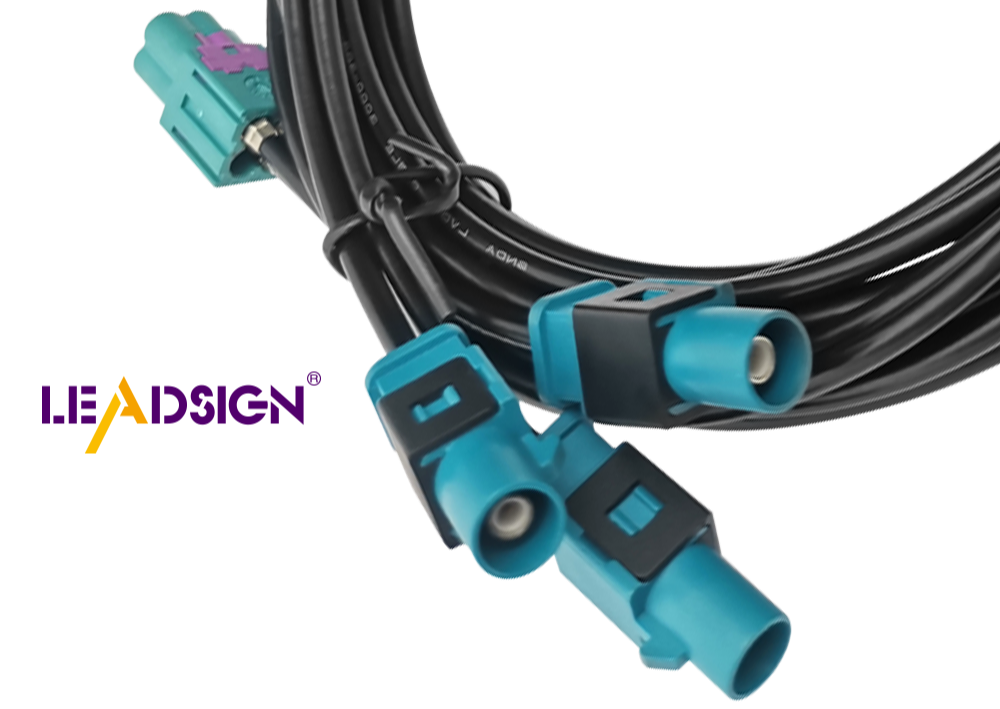

Exploring HSD Connector Essentials for Automotive Applications

Uncovering Advantages of Fakra Connectors in Automotive Industry

Significance of FAKRA Connectors in Automotive Technology