How to Identify Automotive Electrical Connectors for DIY Projects

Understanding automotive electrical connectors types is crucial for DIY enthusiasts. You may encounter issues such as loose wires, corrosion, or excessive heat, which can lead to significant problems if not addressed properly. By familiarizing yourself with the various types of automotive electrical connectors, you ensure your projects remain safe and reliable. Regularly inspecting and cleaning these connectors prevents dust and rust buildup, extending their lifespan. Gaining this knowledge enhances your skills and boosts your confidence when working on automotive projects.

Understanding Automotive Electrical Connectors

When working on car projects, knowing the different automotive electrical connectors types is important. These connectors help parts of your car talk to each other. Let's look at the types, materials, and jobs of these connectors.

Automotive Electrical Connectors Types

Car connectors come in many shapes, each with a special job. Here are some common ones:

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They are popular because they are simple and work well. You see them where quick disconnects are needed, like in fuse boxes.

Bullet Connectors

Bullet connectors have a round shape for easy connect and disconnect. They are used in motorcycle wires and tight spaces in cars. Their design keeps them from coming apart by accident.

Pin Connectors

Pin connectors can handle lots of power. You find them in headlights or starter motors. They have male and female parts that fit tightly together for a strong connection.

Connector Materials

The stuff a connector is made from affects how it works and lasts:

Plastic Connectors

Plastic connectors don't rust and are light. They work well where there's water or chemicals around. Even though they're light, they insulate well for many car uses.

Metal Connectors

Metal connectors, usually copper or brass, conduct electricity well and last long. They handle heat and don't rust easily, making them great for tough jobs.

Connector Functions

Knowing what each connector does helps you pick the right one:

Power Connectors

Power connectors manage high voltage and current for things like batteries or starters. They make sure power moves smoothly through your car's system.

Signal Connectors

Signal connectors send data between electronic parts like engine controls or radios. They keep signals clear so your car's electronics work right.

By learning about these automotive electrical connectors types, you can do DIY projects confidently. Whether fixing a bad connector or upgrading systems, knowing these parts helps you choose wisely for good results.

Tools and Techniques for Identification

When learning about car electrical connectors, having the right tools helps a lot. Let's see what tools you need and how to use them.

Essential Tools

To begin, you'll need some important tools. These will help you find out which connector you're looking at.

Multimeter

A multimeter is very helpful for car connectors. It checks voltage, current, and resistance. Use it to see if a connector works or if there's a problem in the circuit. This tool keeps your DIY projects safe.

Connector Pin Removal Tool

This tool is also important. It lets you take out pins without breaking them. It's great for fixing or checking connectors. With this tool, you avoid breaking pins and can work neatly.

Step-by-Step Identification Process

With your tools ready, let's identify the connectors step by step.

Visual Inspection

First, look at the connector closely. Check its shape, size, and color. Count how many pins there are and their setup. This helps you know which type it is. Picking the wrong one can cause problems, so be careful here.

Testing with a Multimeter

Then test with your multimeter. Set it to check voltage, current, or resistance and touch the probes to the pins. This shows if it's working right. If not, you might need a new one of the same kind unless it's been unreliable before.

By using these steps and tools, you can find out about different car electrical connectors easily. This makes your DIY skills better and keeps your projects safe too! So grab those tools and start learning about car connectors!

Tips for Successful Identification

Finding car electrical connectors can be hard. But with the right steps, you can get it right. Here are some tips to help you.

Common Mistakes to Avoid

You might make mistakes with car connectors. Avoid these to save time and stress.

Misidentifying Connector Types

Connectors look different and do different things. Mixing them up can cause problems. Always check the connector type first. Look at its shape and pins carefully.

Incorrect Use of Tools

Using wrong tools can break connectors. Pliers are not for removing pins; use a pin removal tool instead. This stops damage and costly fixes. Use the right tools like a multimeter and pin removal tool.

Best Practices

Follow good habits to find car connectors easily and quickly.

Keeping a Connector Reference Guide

A guide helps you know different connectors fast. You can find guides online or make your own with notes and pictures from projects. This saves time and cuts down mistakes.

Labeling Connectors During Disassembly

When taking apart a car's wires, label each connector with tape and marker. This avoids mix-ups when putting things back together later.

DIY work is fun but be careful! Electricity is dangerous even in small amounts.

Always turn off power before working on connectors. By following these tips, you'll get better at finding car electrical connectors safely for your DIY projects.

You now know the basics of finding car electrical connectors. Practice often to get better. Start your DIY projects with confidence and use what you learned. Keep a guide nearby, like a Digikey book, to quickly match and find connectors.

"Yes, a Digikey book (the paper one) is great. Grab it and flip through pages. It's quick and easy for me to compare connectors."

To learn more, check online sites, groups, and how-to videos. These will help you understand better and improve your skills. Have fun tinkering!

See Also

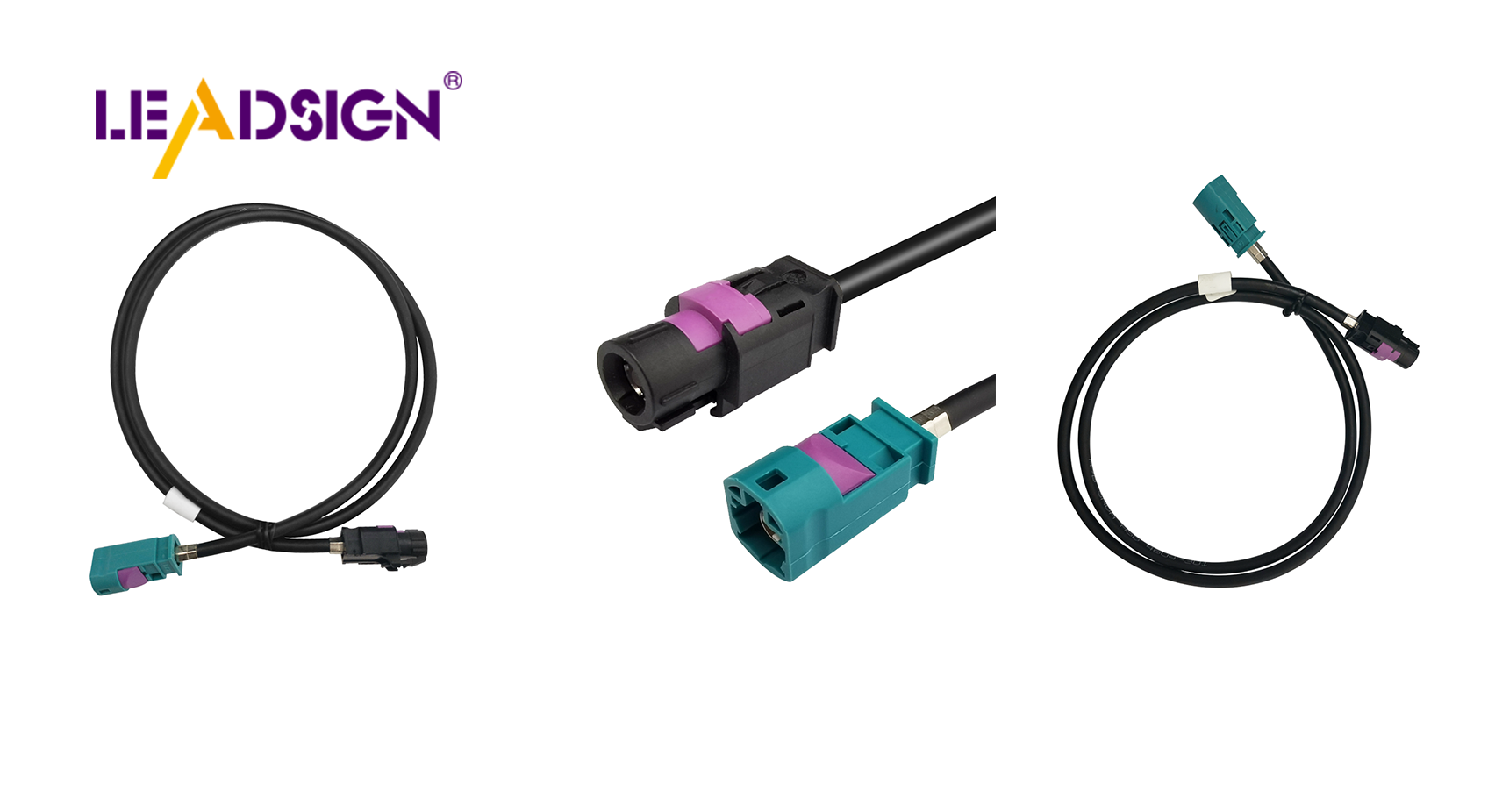

Exploring the Advantages of Fakra Auto Connectors

Understanding the Pros of FAKRA Auto Connectors

The Significance of FAKRA Connectors in Auto Uses