How to Identify Auto Wire Connector Types for Replacement

Finding the right auto wire connector types is crucial for maintaining your vehicle's electrical system. It is essential to ensure that the connectors are secure and free from rust to prevent potential issues. The number of pins in the connector and environmental conditions play a significant role in the likelihood of connector issues. Selecting the appropriate auto wire connector types enhances the safety and reliability of your car's electronics.

Understanding Auto Wire Connector Types

Knowing about different wire connectors helps keep your car's electrical system working well. Each connector type has its own job and benefits. Let's look at the types and what makes them special.

Types of Auto Wire Connectors

Blade Connectors

Blade connectors are very common in cars. They have a flat metal piece that slides into a slot. These are used often because they are easy to use and connect well. They work great when you need to unplug and plug wires back in often.

Bullet Connectors

Bullet connectors look like small bullets with their round shape. They hold tightly but are easy to attach or remove. These are good for places where shaking might happen, as they stay connected firmly.

Butt Connectors

Butt connectors link two wire ends together. They help join wires so electricity flows smoothly. You use them when fixing or adding more wires in your car.

Ring and Spade Terminals

Ring and spade terminals connect wires to screws or studs. The ring makes a full circle, while the spade is open-ended, making it simple to attach or detach. They're used for grounding or battery connections.

Materials Used in Connectors

The materials of wire connectors affect how well they work and last.

Plastic

Plastic connectors don't rust and are light. They're good where there's moisture but can't handle high heat like metal ones can.

Metal

Metal connectors, made from copper or brass, conduct electricity well and last long. They're fit for hot areas and ensure strong connections. Some have gold plating for better performance in important systems like airbags.

Connector Sizes and Ratings

Knowing sizes and ratings helps pick the right connector for your task.

Gauge Sizes

Gauge size tells how thick the wire can be that fits the connector. Matching this ensures a snug fit and best performance.

Current Ratings

Current ratings show how much power a connector can handle safely without overheating or failing.

By learning about these wire connector types, materials, and details, you make smart choices when changing your car's electrical parts. This knowledge boosts your car's safety, reliability, and keeps it running well over time.

Steps to Find the Right Connector

Picking the right car wire connector can be hard. Breaking it into steps helps. Let's learn how to find the correct one for your car.

Look at the Old Connector

Start by looking closely at the connector you need to change. This helps you know what you're dealing with.

Check It Out

First, look carefully at the connector. See if there is any damage or rust. A clean connector usually works well. If it's rusty or discolored, it might need replacing. Notice how many pins and its shape; these are key for matching.

Look for Damage

Next, check for damage. Wiggle it gently to see if it's loose. A good connector should not move easily. Look for cracks in the plastic cover. These mean it might not work well.

Match Type and Size

After checking, find a match by knowing types and sizes of connectors.

Use a Chart

A chart can help a lot here. It lets you compare your connector with others available. Charts list connectors by type, size, and pin setup. Matching these details narrows choices down.

Measure It

Measuring tools help too. Use a ruler or caliper to measure exactly. Measure pin diameter and overall size of the connector so you pick one that fits right.

Think About Environment

Where the connector is used matters a lot for its performance.

Heat Resistance

Think about temperatures it will face. Some connectors handle high heat well. If your car is in hot places, choose ones made for heat.

Water Protection

Water can rust connectors over time. If near water or humidity, choose ones with good water protection like plastic ones which resist moisture well.

By following these steps, you can find the right car wire connectors confidently. This ensures they fit properly and make your car's electrical system safe and efficient.

Tips for Changing Car Wire Connectors

Changing car wire connectors can be tough. But with the right tools and steps, it's easy. Let's see what you need and how to do it.

Tools You Need

Before starting, get the tools ready. Right tools make work simple and connections strong.

Crimping Tools

Crimping tools are key for joining wires to connectors. They squeeze connectors onto wires tightly. Pick a crimping tool that fits your connector size for best results.

Wire Strippers

Wire strippers take off wire coverings. This tool shows the metal part without harm. Choose a stripper that matches your wire's thickness.

Steps to Change Connectors

With tools ready, follow these steps to change car wire connectors well.

Taking Off Old Connector

First, gently remove the old connector. Pull it from the wire carefully so you don't break it. If stuck, use a small tool to help pry it off.

Getting Wire Ends Ready

Next, strip about half an inch of covering from wires. Use your strippers here. Make sure exposed wires are clean with no rust for good connection.

Putting On New Connector

Now put on the new connector. Slide bare wire in and use crimper to secure it tight. Ensure it's snug so wire doesn't slip out easily.

Checking New Connection

After changing, test new connection to check if it works right.

Checking Secure Fit

Ensure new connector fits well by wiggling it gently. A tight fit means it won't come loose over time keeping connection steady.

Testing Functionality

Lastly, test if everything works by turning on electrical system. If all is fine, you've changed car wire connectors successfully!

By using these tips and steps, you can change car wire connectors confidently keeping your vehicle's electric parts safe.

Replacing car wire connectors right is very important. It keeps your car safe and working well. Follow the steps in this guide to do it correctly. Fixing your car's wires isn't just about solving issues. It's also about stopping them before they start. Check your car often and change parts when needed. This helps your car run smoothly. Take care of your car, and you'll have a safer ride that you can trust. Learn more about automotive wire connectors.

See Also

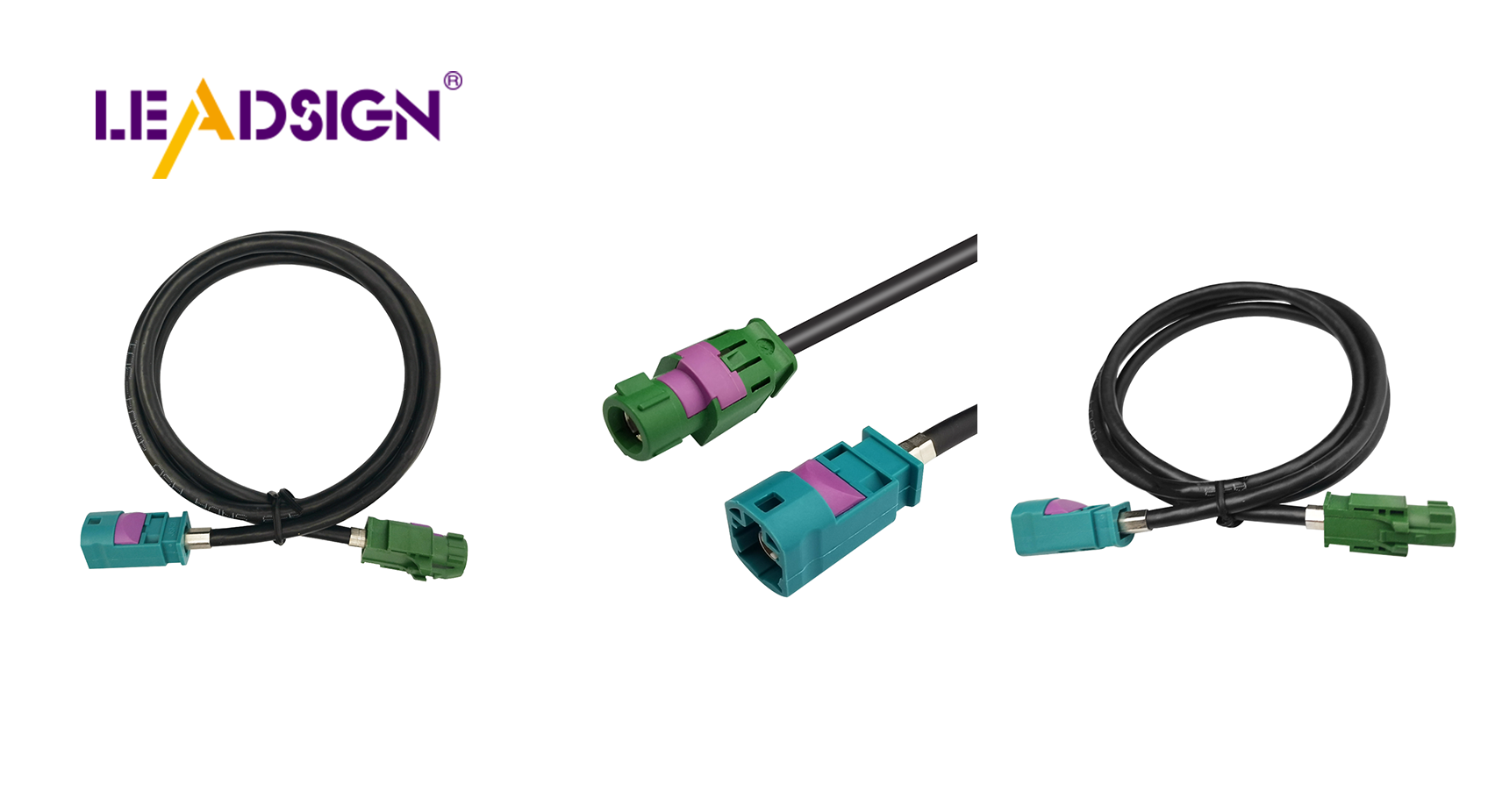

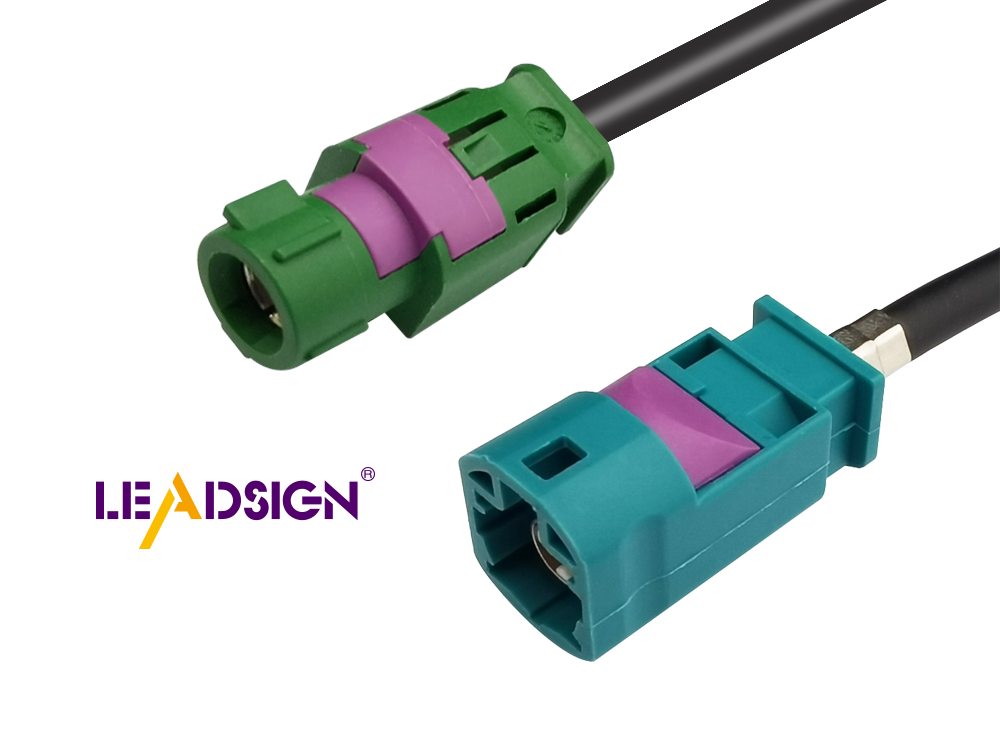

Exploring Ford Fakra Connector Technology

Essential HSD Connector Knowledge for Automotive Sector

In-Depth Analysis of HSD Connector Technology