HSD Cable vs Traditional Auto Wire in Automotive Electronics

In the realm of automotive electronics, wires play a crucial role in ensuring optimal vehicle performance. Both HSD Cables and traditional automotive wires are integral components. HSD Cables are specifically designed for high-speed data transmission, making them ideal for advanced automotive applications. In contrast, traditional automotive wires are dependable for basic functions. Understanding the differences between HSD Cables and regular automotive wires is essential for selecting the most suitable option for automotive electronics requirements.

Definitions and Features

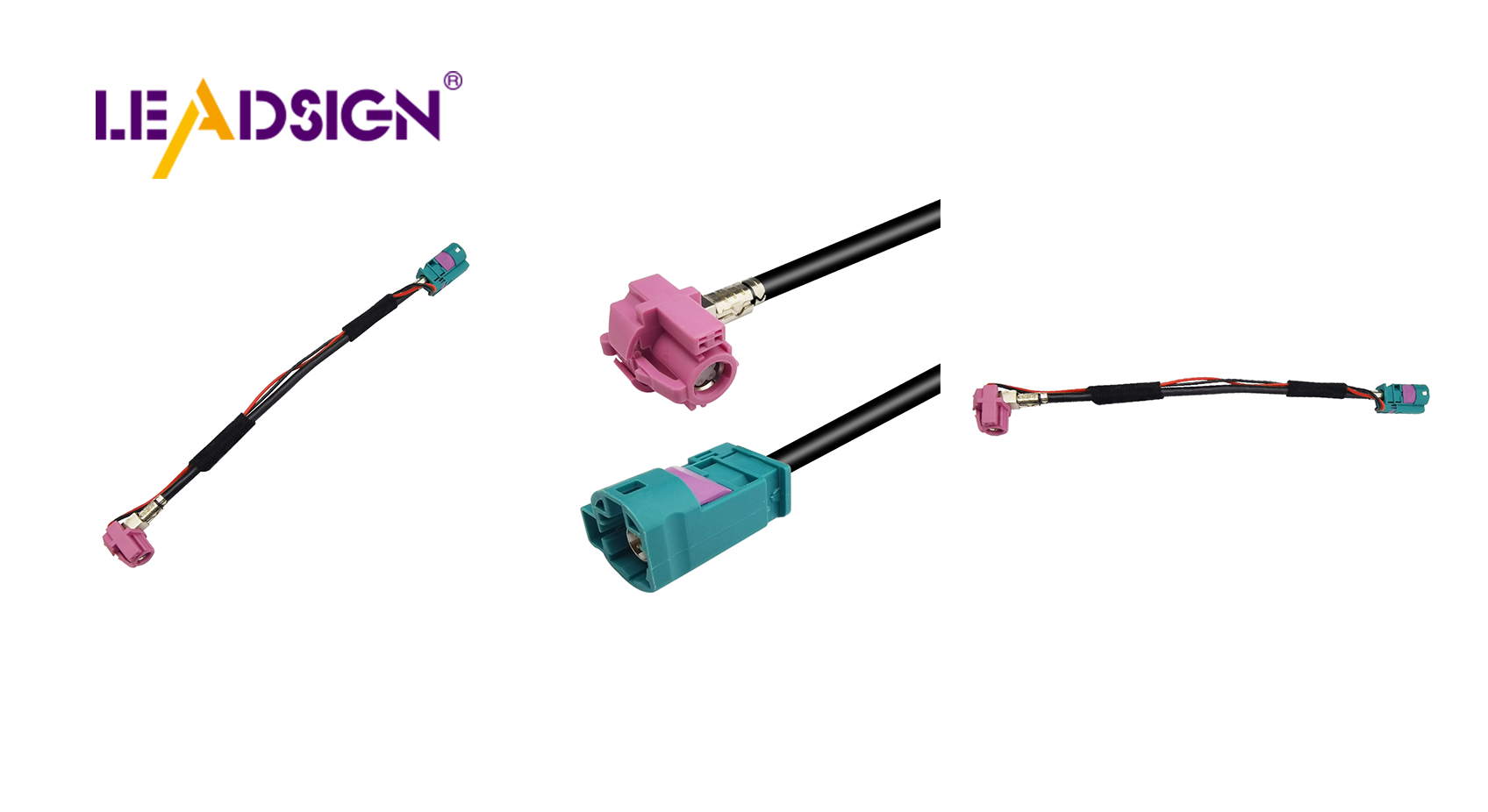

HSD Cables

Definition and Purpose

HSD Cable means High-Speed Data Cable. It is made to send data fast. Cars need HSD Cable for smart systems. Its job is to move data quickly in cars.

Key Features

HSD Cable has important features. Twisted wires help it work well. It keeps signals strong over long distances. HSD Cable is built tough for cars today.

Common Applications in Automotive Electronics

Cars use HSD Cable a lot. Smart driving systems need it for good data flow. Music and video systems use it for clear sound and pictures. It also helps connect USBs and internet in cars.

Traditional Auto Wires

Definition and Purpose

Traditional auto wires do simple jobs in cars. They move power and signals around the car parts. Their job is to keep the car running right. These wires have been used in cars for a long time.

Key Features

Traditional auto wires have special traits. They are made simply but last long for easy tasks. They are cheap and easy to use, perfect for normal car needs.

Common Applications in Automotive Electronics

These wires are used all over cars. Lights need them to get power. Sensors and switches connect with these wires too. They help basic car parts without needing fast data transfer.

Comparative Analysis

Performance

Bandwidth Capabilities of HSD Cable vs Traditional Auto Wire

HSD cables can send lots of data fast. They are made for quick data moves in cars. This makes them great for new car tech. Regular wires can't do this. They only work for simple electric jobs. Fast data sending isn't possible with regular wires.

Signal Integrity in Automotive Electronics

HSD cables keep signals strong and clear. Their twisted design stops signal problems. This helps send clear data far away. Regular wires don't keep signals as well. Problems mess up regular wire signals. New car systems need good, strong signals.

Installation

Ease of Installation for HSD Cable and Traditional Auto Wire

HSD cables are easier to put in cars. Their design makes setup quick and simple. This saves time when building cars. Regular wires need more work to install. They take longer because they are more complex. Car makers like easy setups.

Labor Requirements in Automotive Electronics

HSD cables need less work from people to set up. Their simple design cuts down on labor needed. This means lower costs to make cars with them. Regular wires need more hands-on work to install right. More complex wiring needs more workers.

Cost-Effectiveness

Material Costs of HSD Cable vs Traditional Auto Wire

HSD cables cost more to make because they're high-tech. Companies spend on good materials for these cables. Regular wires are cheaper to produce due to their simplicity, which lowers costs.

Long-term Value in Automotive Electronics

HSD cables last long and work well over time, making them worth the money spent at first; advanced car systems rely on them for better performance, while regular wires save money now but don't perform as well later on.

Practical Uses

New Car Uses

When HSD Cables Are Best in Cars

HSD cables send data fast. Smart car systems need them for quick info. They help music and video work well in cars. HSD cables make USBs and internet strong in cars. They are tough and last long even in bad weather.

When Regular Wires Are Best in Cars

Regular wires do simple jobs. Car lights use regular wires for power. Easy sensor links use these wires too. Regular wires save money for small tasks. Their simple design makes fixing easy.

HSD cables are great for car electronics. They send data fast, helping cars talk better. Their strong build keeps signals clear and saves setup time. HSD cables work well for smart systems like music and driver help. Regular wires are good for simple jobs because they are cheap and easy to use. Car makers should pick HSD cables when lots of data is needed. Regular wires fit where little data is moved.

See Also

Benefits of HSD Connectors for Automotive Applications

Significance of HSD Connectors in Automotive Sector

Fundamentals of HSD Connectors in Automotive Sector

Investigating Benefits of HSD Connectors in Vehicle Cameras

Benefits of HSD Connectors for Vehicle Entertainment Systems