How Vehicle Connectors Work and Their Common Types

Vehicle connectors are important parts that link electrical circuits. They help power and signals move easily, keeping car systems working well. Over time, these connectors have evolved to fit the needs of the car industry. They are now smaller, faster, and perform effectively in tough conditions.

Key Takeaways

Vehicle connectors are essential for linking electrical circuits in cars, ensuring that systems like brakes and infotainment function properly.

Choosing the right connector type based on the specific needs of your vehicle—such as high currents for brakes or weatherproof options for outdoor use—can significantly enhance safety and reliability.

Modern connectors are designed to withstand harsh conditions, so consider factors like environment and strength when selecting connectors to ensure long-lasting performance.

Role in Automotive Electrical Systems

Automotive electrical connectors are key to keeping cars working well. They connect different parts of the car's electrical system. For instance, pin connectors carry strong currents to power the engine and lights. Socket connectors handle weaker currents for things like sensors. Barrel connectors manage RF signals for GPS and audio systems. Without these connectors, car systems wouldn’t work properly and might fail.

Each connector is made for a specific job. Some help control the powertrain, while others are for safety systems like brakes. They also allow fast data transfer for features like driver-assistance systems. By keeping connections stable, these connectors make cars safer and more efficient.

Basic Components of Automotive Connectors

Every automotive electrical connector has important parts that work together. Here’s a simple list:

Contacts: These are the main parts that connect electricity. They have male and female pieces that fit together.

Shell: This is the outside cover that protects the connector and keeps it aligned.

Insulators: These stop short circuits by holding and separating the contacts.

Accessories: These extra parts add protection or special features when needed.

Each part is built to handle tough conditions and last a long time.

Ensuring Reliable Power and Signal Transfer

Modern automotive electrical connectors are made to handle hard conditions. They resist heat, vibrations, and moisture. They also block electromagnetic interference, keeping connections steady. This is very important for systems like brakes and transmission control.

These connectors help systems talk to each other. They control fuel injection and ignition timing, making engines work better. They also manage infotainment systems for a smooth experience. Whether it’s sending power or data, these connectors are the heart of a car’s electrical system.

Common Types of Automotive Connectors

There are many types of car connectors for specific uses. Let’s look at some of the most common ones.

Blade Connectors

Blade connectors are simple and work well. They use flat metal blades to join wires to receptacles. These are often used in speakers or thermostats for direct connections. The wires are tightly attached, making the connection strong. Their easy design makes them very popular in vehicles.

Pin and Socket Connectors

Pin and socket connectors work together as a team. Pin connectors are strong and handle high currents easily. Socket connectors hold pins securely, keeping the connection steady. They are great for systems like engine sensors or lights. These connectors are some of the most useful in cars.

Weatherproof Connectors

Weatherproof connectors can handle tough conditions. They have seals like gaskets or o-rings to block water and dust. This makes them perfect for outdoor parts like headlights or exposed wires. Some even have rubber covers to stop rust. These connectors are needed for harsh environments.

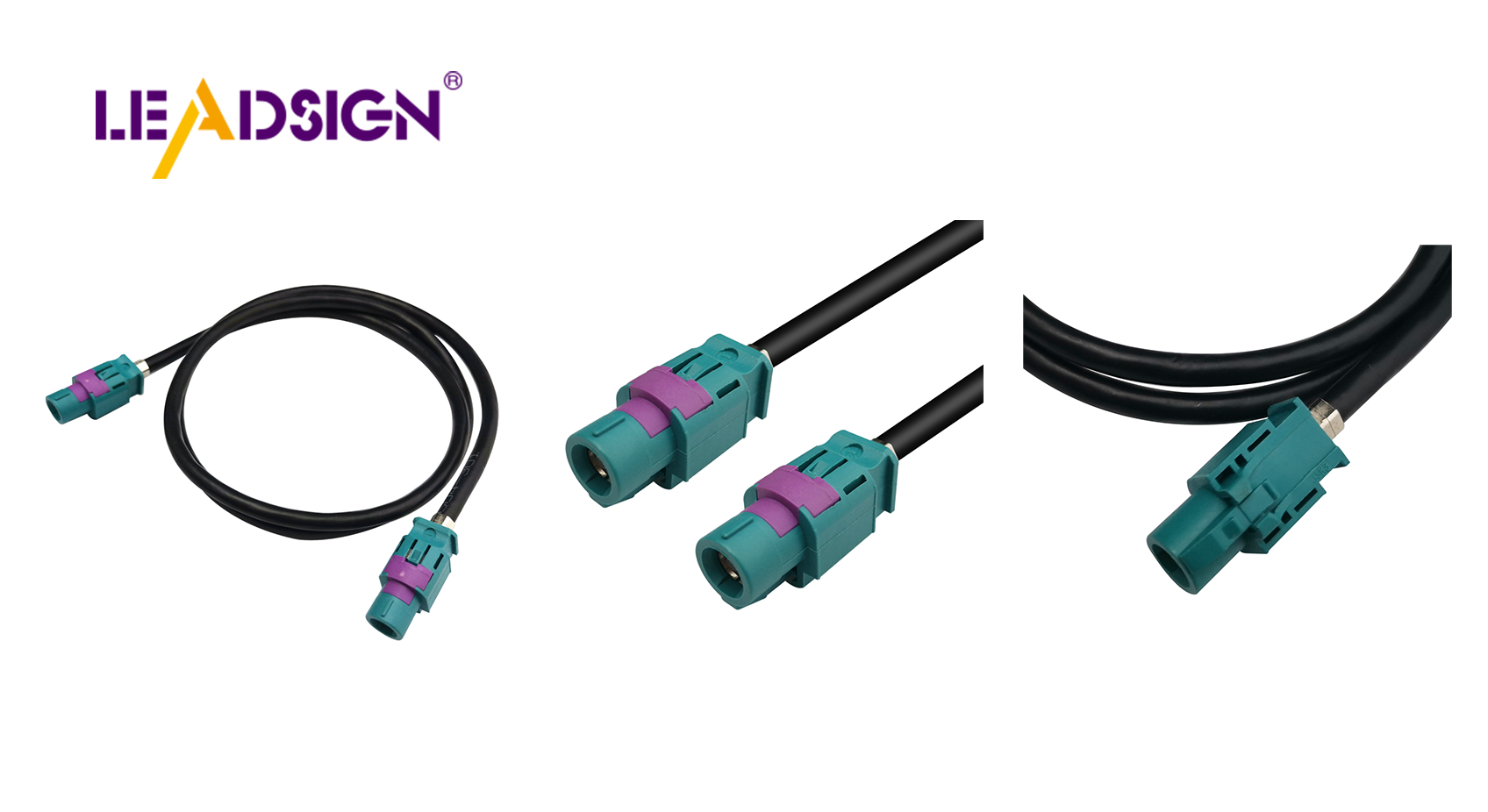

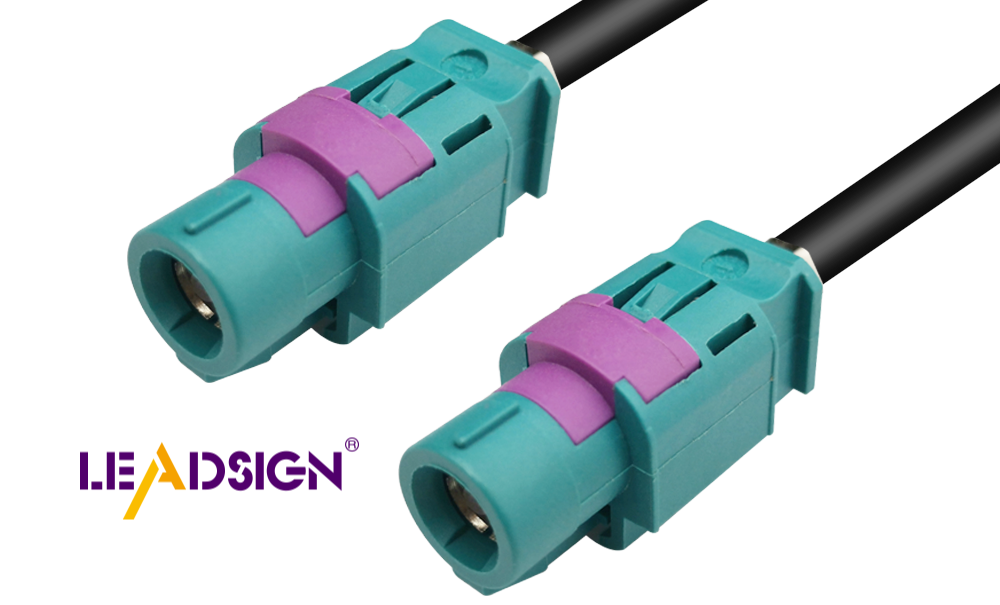

High-Speed Data Connectors (e.g., HSD Connectors)

High-speed data connectors, like HSD connectors, are made for modern cars. They allow fast data transfer for screens, USBs, and cameras. These connectors keep infotainment and digital systems working smoothly. Their advanced design is key for today’s tech-filled vehicles.

Tips for Picking the Best Automotive Connector

Choosing the right connector for your car can seem hard. But with some tips, it gets easier to decide.

Matching Connector Type to Car Needs

Different connectors do different jobs in cars. For example, brakes need connectors for strong currents. Lights need ones that resist rust. Electric cars need connectors for high voltage.

Picking the right connector keeps your car working well. Think about the car's electrical area, type, size, material, and quality.

Here’s a simple guide to match connectors to their jobs:

Brake systems: Use connectors for high currents.

Lighting circuits: Pick rust-resistant connectors.

Infotainment systems: Choose fast data connectors.

Electric vehicles: Use high-voltage connectors.

Thinking About Environment and Strength

Where the connector is used matters a lot. If it faces heat, water, or dirt, pick strong ones. Copper or brass connectors are good for strength and power flow. Sealed connectors are great for wet areas.

Environment: Use connectors with protection against heat, water, and dirt.

Strength: Locking and strain relief features help connectors last longer.

Checking Electrical System Match

Make sure connectors fit your car’s electrical system. Check voltage and current ratings to avoid problems. High-density connectors are good for signals and future upgrades.

Current rating: Ensure connectors handle the system’s current.

Voltage rating: Pick connectors for the system’s voltage.

Contacts: More contacts mean better performance.

By following these tips, your car’s electrical system will stay reliable and work well.

Vehicle connectors are key parts of a car's electrical system. They help systems like airbags and infotainment work properly. Different connectors have different uses. Crimp connectors make strong connections, while weatherproof ones handle tough weather. Using good connectors improves safety, reliability, and driving comfort.

FAQ

What do vehicle connectors do?

Vehicle connectors link electrical parts in cars. They move power and signals, helping systems like lights, sensors, and screens work well.

How can I pick the right connector?

Think about what your car needs. For example:

High currents: Choose pin connectors.

Wet areas: Use weatherproof connectors.

Infotainment: Select high-speed data connectors.

Can I change a vehicle connector myself?

Yes, if you know how to use basic tools. Read the manual, pick the right connector, and align it correctly. For tricky systems, ask a professional for help.

💡 Tip: Always unplug the battery before fixing electrical parts!

See Also

Why Fakra Connectors Matter in Today’s Vehicles

Understanding HSD Connectors for Automotive Applications

Fakra Connectors: Essential Components in Automotive Design