How to Use Auto Wire Connector Types for Reliable Connections

Car wiring needs strong connections. They help car parts talk well. This keeps things working safely and smoothly. Auto wire connectors, including various types like butt and spade connectors, play a vital role in ensuring reliable connections in automotive systems. These connectors are designed to withstand heat, cold, and wetness, preventing rust and maintaining optimal performance in your vehicle. Understanding the different auto wire connector types can significantly enhance the functionality of your car's electrical system.

Understanding Auto Wire Connector Types

Knowing about car wire connectors is important. They help your car's electrical parts work well and safely. Let's look at some common and special wire connectors you might see.

Common Types of Auto Wire Connectors

Butt Connectors

Butt connectors are often used in cars. They join two wires together securely. This keeps your car's circuits working right. They're popular in audio systems for clear sound.

Spade Connectors

Spade connectors have a fork shape. They make it easy to connect or disconnect wires quickly. You see them in car lights where wires need frequent changes.

Ring Connectors

Ring connectors attach wires to screws or studs strongly. They're used in engine wiring, needing a solid connection that stays put even with movement.

Specialty Connectors

Heat Shrink Connectors

Heat shrink connectors add extra reliability. After crimping, heat shrinks the tube around the connection making it waterproof, protecting from water and rust.

Quick Disconnects

Quick disconnects let you remove wires fast and easily. They're great for places where parts change often, like digital systems, saving time on maintenance.

T-Tap Connectors

T-Tap connectors let you add new circuits without cutting existing wires. They're useful in car electronics for expanding or changing setups easily.

Knowing these wire connector types helps pick the right one for any job, ensuring your car's electrical system works well and lasts long.

Picking the Best Connector for Your Car

Choosing the right auto wire connector is very important. It helps your car's electrical system work well. Let's look at what you should think about and when to use different connectors.

Things to Think About

When picking a connector, consider these key things:

Wire Size Match

First, check if the wire size matches. Connectors come in sizes for different wires. Using the wrong size can cause bad connections or harm. Always match the connector with the wire size for a good fit.

Weather Conditions

Next, think about weather conditions. If your car faces tough weather, like hot or wet places, pick connectors made for those situations. Connector Experts say it's crucial to choose connectors that fit your car's needs to avoid problems.

Power Needs

Lastly, check power needs. Different connectors handle different power levels. Make sure the connector can manage the power your car uses. This stops overheating and keeps things working well.

Where to Use Them

Various connectors are great in different car parts. Here are some examples:

Car Lights

For car lights, you need connectors that let you unplug and plug easily. Spade connectors are good here because they help change bulbs fast without trouble.

Music Systems

In music systems, clear sound matters a lot. Butt connectors give strong links so your music sounds clear and doesn't stop.

Engine Wires

Engine wires need strong connections that handle shaking and moving around. Ring connectors work best here as they hold wires tight on screws or bolts, keeping them steady even when things get bumpy.

Picking the right connector means knowing what you need and where your car goes often. By thinking about these points and where you'll use them, you keep your car's electrical system strong and working well.

Step-by-Step Guide to Using Auto Wire Connectors

Getting Wires Ready

Before connecting wires, get them ready. This makes sure they connect well.

Taking Off the Cover

First, take off the wire cover. Use a wire stripper tool. Put the wire in the right slot of the tool. Gently squeeze and pull off the cover. Be careful not to harm the wire strands. Now, you see bare wire for connection.

Picking the Right Connector

Next, pick the right connector for your wires. Think about wire size and where it will be used. If it needs to be waterproof, use heat shrink connectors. Match connector size with wire size for a good fit. This is important for a strong connection.

Connecting Wires

Now that wires are ready, connect them well by following these steps.

Crimping Method

Crimping joins wires together tightly. Put stripped wire into connector. Use crimping tool to press connector on wire firmly. A tight crimp holds wire without slipping. This gives a strong connection that handles shaking.

Soldering for More Strength

For more strength, solder it too. Heat soldering iron and touch joint of wire and connector with it. Add solder until it covers connection smoothly. Let cool without moving wires. Soldering makes connections stronger and stops rust in tough places.

Checking Connection

After connecting, check if it's working right.

Look at It Closely

Start by looking closely at it. Make sure wires are fully inside connectors with no loose ends or exposed parts showing outwards from their positions within each other’s boundaries; everything should look neat & secure! Spot any problems before testing electricity flow through them later on during this process!

Test Electricity Flow

Finally test electricity flow using multimeter device set up correctly beforehand so as not miss anything important while doing these tests: touch probes against both ends simultaneously listening carefully either beep sound indicating successful continuity achieved between points tested successfully confirming smooth passage current throughout entire length involved here today!

By doing these steps carefully ensures auto connections stay strong keeping car's electric system running well always!

Picking the right connectors is key for your car's electric system. Good connections keep things safe and working well. Always use good methods with auto wire connectors. Use quality tools and practice crimping often. One person said, "Learn to make strong crimps before starting." Check out Waytek for Deutsch and Weatherpak connectors; they're tough and last long. If you have questions or need help, ask someone or look for more info. Your car needs the best connections!

See Also

Significance of HSD Connectors in the Auto Sector

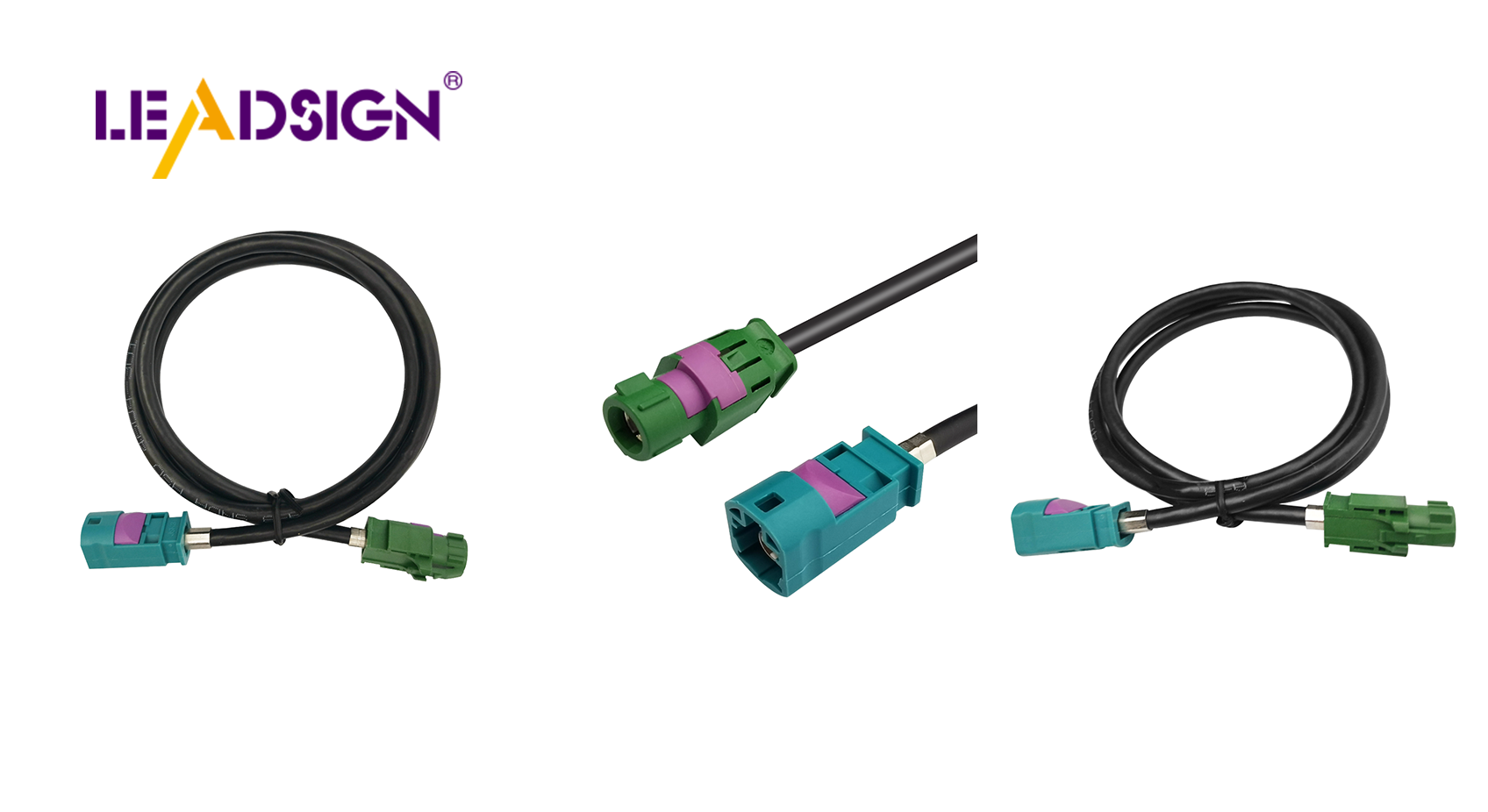

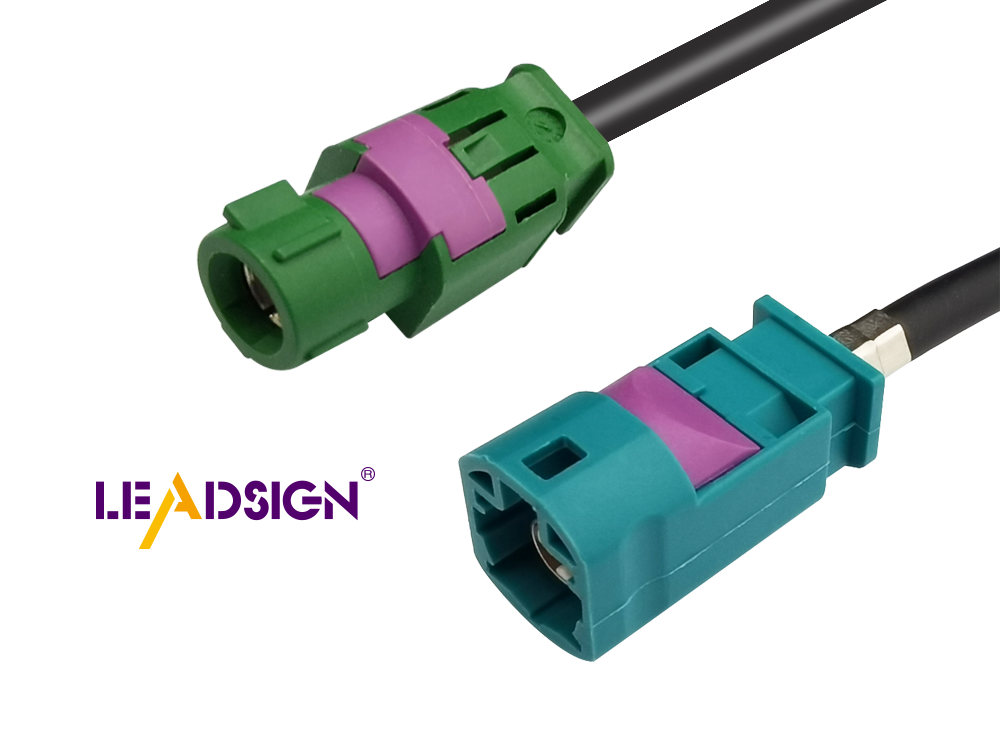

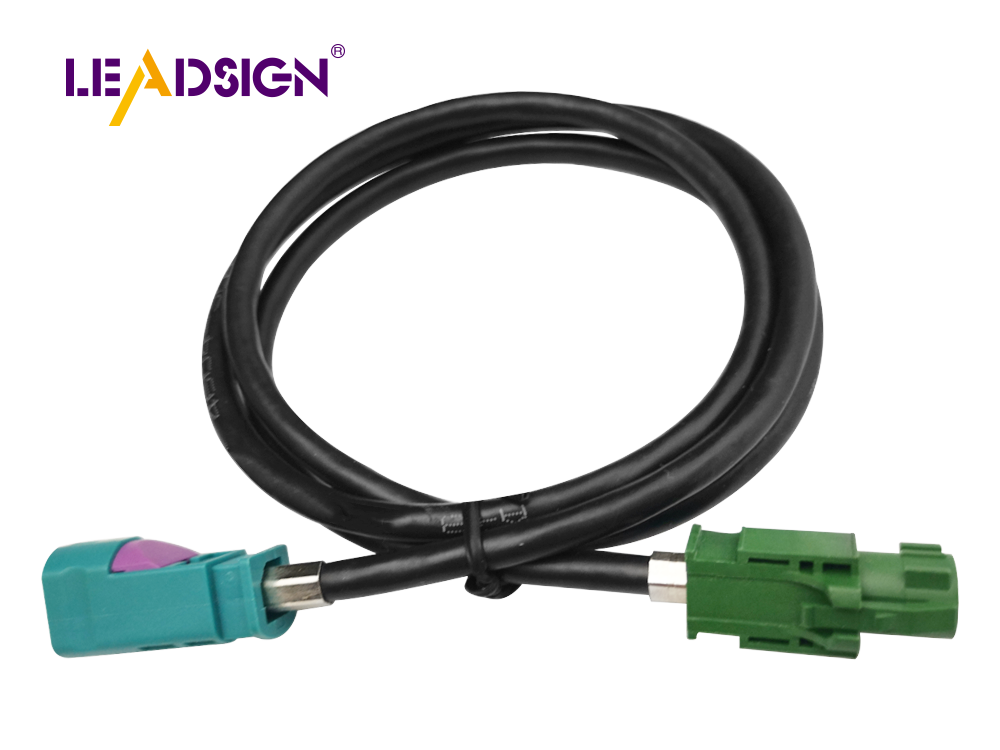

The Significance of FAKRA Connectors in Auto Uses

Benefits of HFM Connectors in Auto Sector