How FAKRA Connectors Enhance Vehicle Communication

Connectors are important for car communication. They help send data between electronic systems. Car makers use FAKRA connectors because they work well. These connectors send data fast, which new cars need. More connected cars and cool features make FAKRA connectors popular. Makers create new designs to meet customer needs. Electric cars and self-driving tech make these connectors even more important.

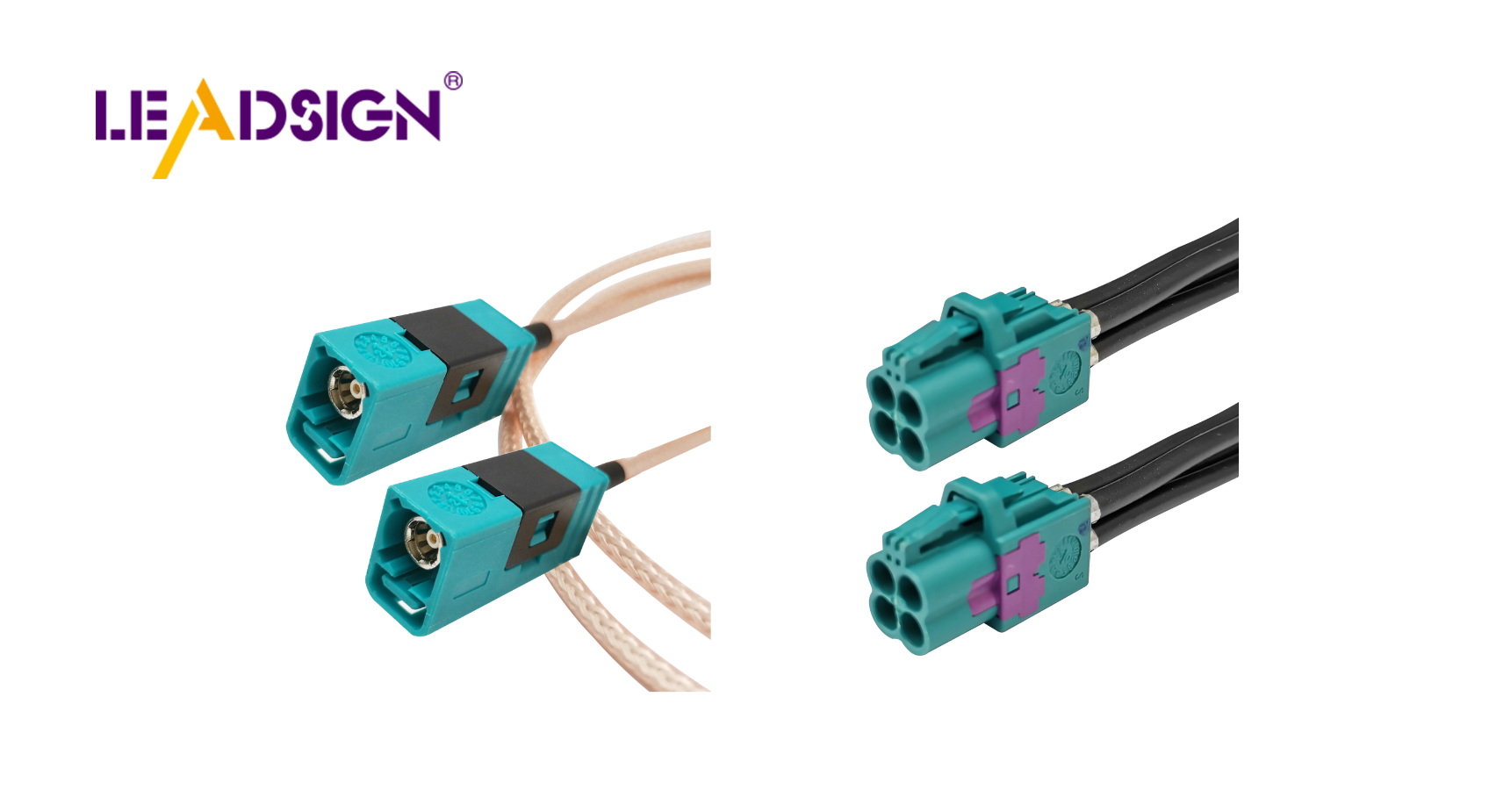

Understanding FAKRA Connectors

Uses in Cars

FAKRA connectors are very important in cars. They help parts talk to each other well. Many car systems use these connectors.

Radio and Telematics

Car radios need FAKRA connectors to work right. These connectors help send strong signals. Telematics also use them for good connections. They stay strong even when it's tough outside, which is great for telematics.

GPS and Self-Driving

GPS in cars uses FAKRA connectors too. They help get the right signals from satellites. Self-driving cars need them as well. These systems must share data correctly to be safe. FAKRA makes sure everything works well.

Design Rules and Details

FAKRA connectors follow strict rules. This helps them work in many ways.

Meeting Standards

FAKRA follows ISO20860-1 and USCAR-18 rules. These rules make sure they are good quality and reliable for cars.

Handling Signals

FAKRA can handle signals up to 6 GHz, which is fast. They match signal strength to keep it clear, making communication better in cars.

Material Choice and How They Work

Cover and End Materials

FAKRA connectors use special materials for covers and ends. Engineers pick materials like PA6, PA66, and ABS for covers. These give strength and bend easily. They also handle heat and tough places well. Choosing the right material helps FAKRA connectors last long in cars.

End materials are very important in FAKRA connectors. Makers use metals like brass or copper for ends. These metals carry electricity well. Coatings like gold or tin make ends work better. The coatings stop rusting and wearing out. This keeps FAKRA connectors working well over time.

Effect on Lastingness and Signal Quality

Lastingness is key for FAKRA connectors in cars. Waterproof parts keep water out. This makes sure they work well when wet. Rust-proof features make FAKRA connectors last longer. These features suit them for many car settings.

Signal quality is vital for FAKRA connectors too. Insertion loss can hurt signal quality. Engineers design them to lower insertion loss. This keeps signals strong when sent through wires. Matching impedance is also crucial. Good impedance matching stops signal bouncing back, making car communication clearer.

Cool Features and Safety

Smart Coding System

FAKRA connectors have a smart coding system. This stops wrong connections in cars. Engineers make them with colored covers. Each color is for a certain use. This helps workers connect parts correctly. The coding system makes assembly safer by cutting down mistakes.

The FAKRA connectors patent shows why exact connections matter. Wrong links can cause problems in communication. The coding system in FAKRA connectors fixes this well. Car makers trust this feature for good car communication.

Automatic Making and Big Production

Automatic making is key for making FAKRA connectors. These methods ensure reliable building steps. Makers use high-tech machines to put together FAKRA connectors. This way, they keep quality the same even when making many.

Big car production gains a lot from automatic making. FAKRA connectors fit big production needs well. Fast processes cut down on making time, saving money for car makers.

Automatic making also improves how precise FAKRA connectors are. Same quality means better work in car systems. Car engineers rely on FAKRA connectors because they last long and work well. Smart coding plus automatic making makes FAKRA connectors vital in today's cars.

Top Makers and Their Products

Rosenberger

Rosenberger is a top maker of FAKRA connectors. They focus on safe coding and strong assembly. Engineers make these to stop wrong connections. This helps car parts talk well. Rosenberger's FAKRA connectors are easy to put together. These features make them last long in cars.

TE Connectivity

TE Connectivity is great at making FAKRA connectors with machines. They use cool tech for good quality every time. RF performance is key for TE Connectivity. The connectors handle fast signals, which new cars need. TE Connectivity follows USCAR rules for safety and work.

Other Important Makers

Many other companies make FAKRA connectors too. JAE, Molex, and Amphenol RF have special features. JAE makes ones with better signal strength. Molex designs small ones for tight spaces in cars. Amphenol RF is known worldwide for smart ideas. These makers add different benefits to FAKRA connectors, helping them work well in cars.

FAKRA connectors are key for car communication. They help send data reliably between car parts. Car makers use them for fast data transfer. Engineers make sure they meet strict rules. FAKRA's future looks bright with new tech improving them. Makers will keep making better FAKRA connectors for new car tech. As electric and self-driving cars grow, more FAKRA connectors will be needed. They will stay important for today's car systems.

See Also

Improving Auto Communication Through FAKRA Printed Circuit Board Connectors

Significance of FAKRA Connectors in the Auto Sector

Discovering Advantages of FAKRA Auto Connectors

Significance of FAKRA Auto Connectors in Contemporary Cars

Significance of FAKRA Printed Circuit Board Connectors in Auto Communication