How Types of Wire Connectors Automotive Influence Performance Standards

Car wire connector types are crucial in automotive systems. They play a vital role in ensuring the proper functioning and safety of vehicles. These connectors facilitate the flow of electricity, preventing major issues such as steering or brake malfunctions. The various types of connectors available can significantly impact the performance and safety of cars. Selecting the appropriate connector that meets specific standards is essential for optimal functionality and safety. It is crucial to choose the right type of connector for each specific application in automotive systems.

Car wire connectors are important in cars. They help electricity flow smoothly, which is needed for cars to work well. Knowing about these connectors helps pick the right one for each job, making cars safer and better.

Crimp connectors are popular because they are reliable and easy to use. They squeeze a metal piece around the wire, making a strong link. This makes them good at handling bumps and tough weather, perfect for cars.

Solder connectors make a lasting link by melting solder on the wire and connector. They give great electricity flow and don’t get loose easily. These are used when a steady connection is needed but take more time to set up than crimp ones.

Push-on connectors are quick to use without tools. They’re handy where wires need frequent connecting or disconnecting, like during tests or repairs. But it’s important they fit well to avoid coming apart by accident.

The materials of car wire connectors affect how well they work and last.

Copper is common because it carries electricity well and bends easily. It stops rusting too, so it lasts long in cars.

Aluminum is lighter than copper but doesn’t carry electricity as well. It’s used when weight matters most but needs careful handling to stop rusting.

Plastic insulation keeps connectors safe from things like water and dirt. It stops short circuits and shocks, which is key in cars.

Performance Standards in Car Wiring

How Well Electricity Flows

Why Good Flow is Important

Good electricity flow is key in car wiring. It helps power move easily through connectors, making car parts work well. High flow means less energy wasted, which keeps cars running their best. Smooth electricity helps things like lights and sensors work right. When connectors let electricity flow well, the car's system works better.

What Changes Flow

Many things change how well connectors let electricity pass. The stuff they're made of matters a lot for this. Copper is great because it lets power move easily and is often used. Aluminum is lighter but doesn’t carry power as well as copper does. How connectors are built also changes flow. A good fit makes less resistance and better power movement. Weather like heat or wetness can change how they work too. Connectors need to handle these to keep working right.

Lasting Strong and Trustworthy

Fighting Off Bad Weather

Connectors need to be strong and last long in cars. They must handle bad weather to keep working over time. Water, dirt, and changing temperatures can harm them slowly. Good ones have covers or coatings to protect them from these things. This stops rusting and keeps connections strong. Strong connectors stay good even in tough spots, keeping the car’s system working.

Staying Useful Over Time

How long connectors last affects how reliable they are in cars. Strong ones mean fewer swaps needed, saving time and money on fixes. Good materials make them last longer too. Checking them often helps them stay useful for a long time too. By picking strong ones, car makers make sure cars stay safe and work well for years.

How Connectors Affect Car Performance

Electrical Efficiency Impact

Connection Strength

Different car wire connectors affect how well connections stay strong. A strong connection lets electricity flow smoothly, which helps car parts work well. Crimp connectors hold wires tightly, even when the car shakes or bumps. This keeps the connection steady and stops problems that can make cars unsafe.

Voltage Drop Issues

Voltage drop is about losing power as it moves through wires. Good connectors lower resistance, so power flows better in cars. Solder connectors are great because they let electricity pass easily, reducing voltage drop. This is important for parts like sensors that need exact power to work right. Choosing low-resistance connectors helps cars run smoothly.

Safety Concerns

Short Circuit Risks

Picking the right wire connector helps stop short circuits. Bad or loose connectors can expose wires and cause faults. Push-on connectors might come loose if not fitted well, leading to shorts. To avoid this, use secure connectors tested for car use.

Fire Safety Measures

Stopping fires is key in car wiring systems. Connectors with good insulation protect against water and dirt, lowering fire risks from sparks or heat. Strong plastic covers help keep things safe by stopping overheating and fires in cars. Using certified safe connectors protects both the car and people inside.

Wire connectors in cars are very important. They help cars work safely and well. There are different types like crimp, solder, and push-on. Each type has special benefits. These benefits affect how well electricity moves and how long they last. Picking the right connector is key to keeping systems working well. It also helps stop problems like short circuits or fires.

Using original car connectors makes sure connections are correct and steady. This shows their importance in today's cars. Choosing the right connectors not only makes circuits better but also keeps things safe. They are a must for cars to work reliably.

See Also

The Significance of HSD Connectors in Automotive Sector

Essential HSD Connector Fundamentals in Auto Sector

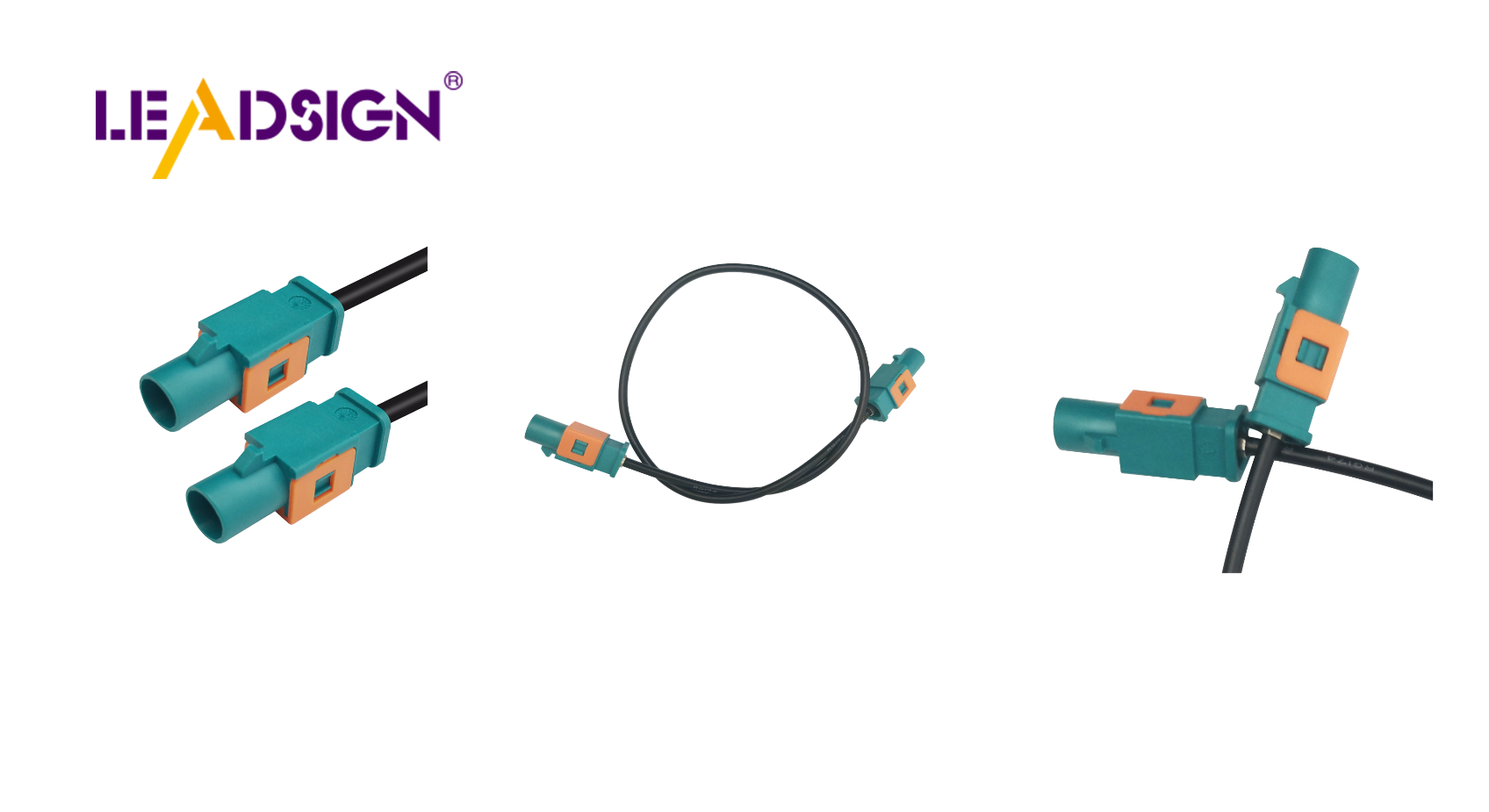

The Significance of Fakra Connectors in Automotive Sector

The Benefits of HFM Connectors in Auto Sector

Improving Data Transfer: The Significance of High-Speed Auto Connectors