High-Speed PCB Design for Automotive Wire Applications

High-Speed PCB Design is very important for cars. It helps data move quickly inside vehicles, which is needed for new car tech. The car PCB market will grow from USD 8.62 billion in 2023 to USD 14.65 billion by 2031. This growth is due to more connected and electric cars. But making these PCBs can be hard. Engineers must think about signal strength, how packed parts are, and what materials to use to keep them working well in fast settings.

Learning About Fast PCB Design

Fast PCB Design is key in today's cars. Engineers need to know important parts and features for best performance.

Important Parts and Features

Top Speed and Quick Change

Top speed means how fast a signal can go back and forth. In Fast PCB Design, engineers think about this to stop signal problems. Quick change shows how fast a signal goes from low to high. Faster changes can cause signal issues. Engineers must balance these things for good car system communication.

Moving Data and Signal Speed

Moving data tells how much data moves in a certain time. Fast PCB Design needs handling these speeds for smooth data flow. Signal speed, or cycles per second, affects data sending. Engineers match moving data with signal speed to stop slowdowns and keep things running well.

Fast vs. High-Frequency PCBs

Knowing the difference between fast and high-frequency PCBs helps design better.

Digital vs. RF Signal Handling

Fast PCB Design uses digital signals needing exact timing. High-frequency PCBs use RF signals that keep strength over long ways. Engineers adjust their plans based on the signal type for best results.

Material Choice and Wave Lengths

Material choice matters in Fast PCB Design. Different materials change signal speed and quality. Engineers pick materials that fit the needed wave length and frequency. This makes sure the PCB works well in cars without losing performance.

Design Considerations for High-Speed PCBs

Component Density and Routing

High-Speed PCB Design needs careful planning. Engineers think about how close parts are. If parts are too close, signals can mix up. This causes crosstalk and errors.

To keep signals clear, engineers plan well. They place parts to avoid mixing. Shorter paths help signals stay strong and clear.

Impedance Control and Differential Signaling

Impedance control is very important here. Impedance means resistance to current flow. Engineers make sure impedance stays the same to stop signal bouncing.

Differential signaling uses wire pairs for signals. It cuts down on interference and keeps signals good. Engineers focus on this for fast data moves.

Material Selection

Picking the right material matters a lot. Materials affect signal speed and quality. Engineers choose materials with good properties.

A low dielectric constant makes signals move fast, which is needed for speed. A low dissipation factor means less energy loss as heat.

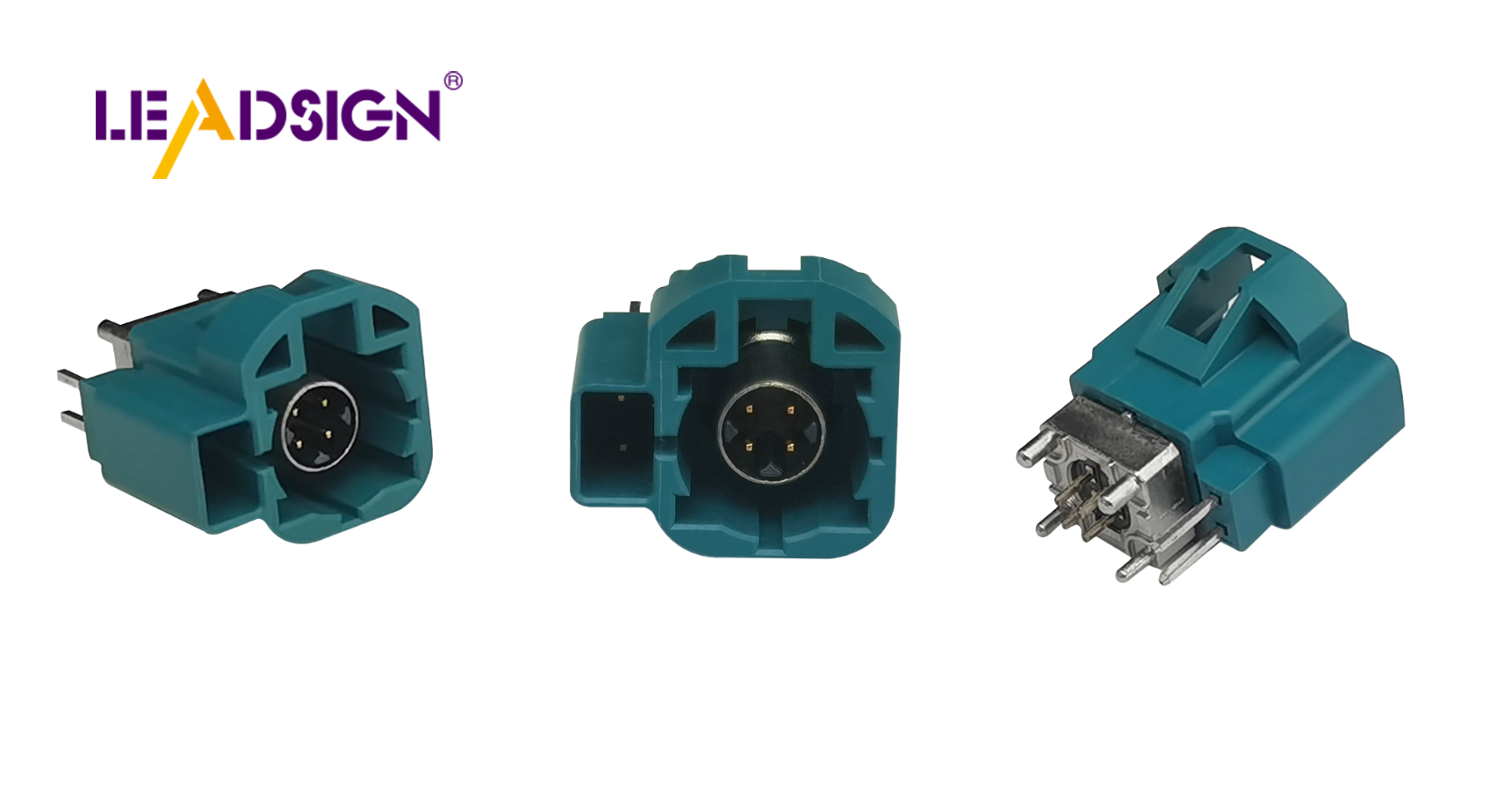

Fast Data Connector Systems

Fast data connector systems are important in High-Speed PCB Design for cars. They make sure data moves quickly and safely, which is needed in new cars.

Features and Rules

Fast data connectors must follow certain rules to work well in cars.

Rules and Standards (like LVDS, Ethernet)

LVDS (Low-Voltage Differential Signaling): This rule helps move data fast using little power. It's used a lot in cars because it works well.

Ethernet: Car Ethernet is strong for car networks. It lets lots of data move easily between car parts.

H-MTD Connector System: This system can handle high frequencies and fast data speeds up to 56G bit/sec. It's made for fast data needs in cars.

Safety Checks and RoHS Rules

Fast data connectors need to pass safety checks like RoHS (Restriction of Hazardous Substances). These checks make sure the connectors are safe and good for the environment.

Uses in Cars

Fast data connectors are used in many car parts, making them work better together.

Entertainment and Dashboard Systems

In entertainment systems, fast connectors help mix sound, video, and maps smoothly without stopping.

Dashboard Systems: These show real-time info like speed or fuel levels quickly with fast connectors.

Connection Options (like USB, Bluetooth)

Fast data connectors help connect the car to other devices easily.

USB: Fast USB lets quick sharing between the car and things like phones or tablets for charging or music.

Bluetooth: Bluetooth uses fast connectors for steady talks between the car and wireless gadgets, helping with calls or music.

Planning PCB Layouts for Fast Use

Making a PCB layout for fast use needs careful planning. Engineers focus on key parts to make it work well.

Placing Parts and Routing Signals

Putting parts in the right spot is crucial. Engineers place parts smartly to stop interference and keep signals strong.

Stopping Crosstalk and Managing Heat

Crosstalk happens when close signals mix up. To stop this, engineers keep enough space between lines. They also use shields to cut interference. Managing heat is important too. Parts should be placed to let heat escape, stopping overheating.

Why Ground Planes Matter

Ground planes are very important. They help reduce signal problems like electromagnetic interference (EMI). Engineers need continuous ground planes for good signal quality.

Picking the Right PCB Maker

Choosing the right maker is key for success. The maker’s skills affect how good the final product is.

Using CAD Software Tools

CAD tools help engineers design and test layouts. These tools find issues like reflections and crosstalk. By testing, engineers can fix paths for better performance.

Handling Manufacturing Differences

Manufacturing differences can change how PCBs work. Engineers must work with makers to handle these changes. This teamwork makes sure products meet plans and work well in cars.

High-speed PCB design is very important for cars. Engineers need to focus on signal strength, part closeness, and material choice for best results. PCB technology will keep getting better. Makers are building smaller, stronger, and greener PCBs. Flex PCBs help make designs that bend but still work well. New trends like 3D printing and HDI technology make things faster and greener. These changes will keep helping the car world with better and more reliable solutions.

See Also

Improving Automotive Data Transfer with FAKRA PCB Connectors

The Benefits of FAKRA PCB Connectors for Automotive Use

Advantages of FAKRA PCB Connectors for Automotive Purposes

Improving Automotive Connectivity with FAKRA PCB Connectors

Improving Data Transfer: The Significance of High-Speed Automotive Connectors