High-Speed PCB Design with Auto Wiring Solutions

High-speed PCB design is key in modern electronics. It helps devices like computers and phones send signals fast. This design reduces signal problems for reliable data. Auto wiring makes this better by improving trace paths and parts placement. This keeps power steady and cuts down interference. In industry, these changes help build strong systems. They meet the needs of fast data and complex electronics.

Learning About Fast PCB Design

Fast PCB design is very important in today's gadgets. It helps devices send data quickly without losing quality. This part talks about the main things that make fast PCB design work.

Important Things to Know

Top Speed and Quick Change

Top speed and quick change are key in fast PCB design. They show how fast a signal moves from low to high. Faster changes mean more data can be sent, which is needed today. Engineers must think about these to stop signal problems and keep messages clear.

Sending Data Quickly

Sending data quickly is another big part of fast PCB design. It means how much data goes through in a short time. High speeds need careful planning to keep signals strong. Engineers must make sure speed doesn't ruin the message, keeping it clear.

Hard Parts

Parts and Path Crowding

Parts and path crowding affect fast PCB design a lot. As gadgets get smaller, more parts go on tiny boards. This makes paths tricky, risking signal problems. Designers must plan well to cut down on mix-ups and keep data moving right.

Different Connections Matter

Different connections also change fast PCB design. Links like USB or Ethernet need special setups on boards. Each has its own needs for good performance. Engineers must know these links to make good fast PCBs.

Science Research Shows:

Fast PCB design makes boards that handle quick signals.

It needs both electric and build balance for good work.

Keeping signals clear is key for high-speed use without mess-ups.

By knowing these important things, engineers can make fast PCBs that fit today's tech needs. This helps devices work well, sending data quickly as needed now.

Important Things in Fast PCB Design

Fast PCB design needs good planning for best work. Engineers must focus on key parts to keep signals strong and reliable.

Line Design for Sending Signals

Keeping Signals Clear

Keeping signals clear is hard in fast PCB design. Engineers use tricks to stop loss and fuzziness. They use special paths and ends to keep signals sharp. For LVDS boards, neat paths and spaces are important. These stop echoes and keep signals clean.

Keeping Power Steady

Keeping power steady is very important in fast PCB design. Engineers make sure power lines give the same voltage always. Good decoupling and using power layers cut noise and bumps in voltage. This steadiness helps parts work fast without problems.

Placing Parts and Lining Signals

Stopping Noise and Crosstalk

Noise and crosstalk can mess up fast PCB design a lot. Right part placing and lining help stop these troubles. Engineers should keep quick signals away from noisy parts. Covering wires and using two-signal ways lower noise, keeping paths clear.

Matching Lines and Two-Signal Ways

Matching lines is key in fast PCB design. Engineers match line size to the parts they join with. This stops signal bounces and losses. Two-signal ways, used often in quick jobs, make signals better by cutting electric noise (EMI). It keeps signals strong even when things get tricky.

"Checking signal quality after making shows how tests help keep it good."

By following these important things, engineers can make fast PCBs that fit today's tech needs well. These designs help send data quickly with no trouble, which is needed now.

Auto wiring solutions help make high-speed PCB design better. They make the design process easier and fix problems before they start.

CAD tools are very important for fast PCB design. They let designers see and improve complex circuits.

Simulation tools like HyperLynx DRC are used to model circuits. They find problems before making the real thing. Engineers use these tools to test different ideas, making sure designs work right. This stops mistakes and makes PCBs better.

Altium Designer® has great tools for fast design and layout. The Altium 365™ platform helps teams share projects easily. This makes creating prototypes faster, saving time and money on changes.

Picking the right connectors is key in fast PCB design. Connectors need to meet certain needs for good performance.

Connectors must handle circuit voltage and current well. Engineers check these needs to stop overheating and keep things stable.

High-density connection solutions are needed as gadgets get smaller. Connectors must fit many links in tiny spaces now. Engineers think about how connectors fit together safely to keep signals clear and avoid interference.

Using smart CAD tools and picking good connectors is crucial for successful high-speed PCB design.

By knowing how auto wiring works, engineers can make their designs work better and last longer in today's tech world.

Uses and Future Ideas

Factory and Car Uses

Fast Data Cables

Fast data cables are important in cars. They help parts talk to each other quickly. As cars get smarter, they need faster data sharing. These cables make strong links for fast signals. This is key for things like cameras and USB ports, where keeping signals clear is a must.

Following Rules and Guides

In factories, following rules keeps electronics safe. For cars, rules like ISO 26262 for safety are vital. These guides help make sure car electronics work right. By sticking to these rules, makers can build safe car parts that fit well together.

New Tech Ideas

New Connector Designs

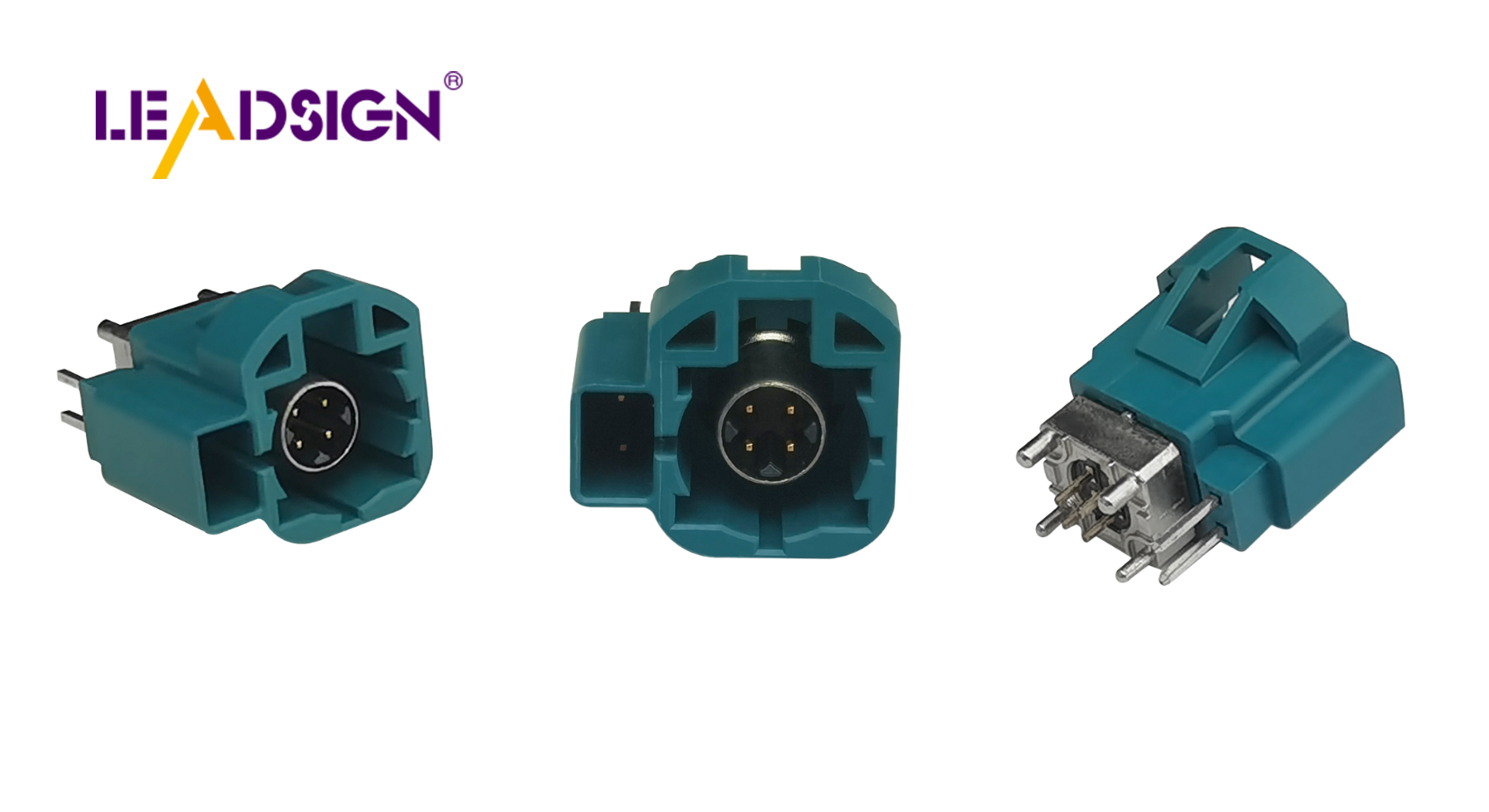

New connector designs are changing fast PCB design. As gadgets get smaller, connectors must fit tiny spaces but still work well. New designs help them handle more data and last longer. Things like special shapes and colors make them easy to use and reliable.

Future of Smart Wiring

Smart wiring's future is in using new tech in cars. As cars connect more, smart wires will grow too. They'll send data and watch power use at the same time. Using IoT tech, they can check car health live, making cars safer and better.

"Car electronics' future depends on new ideas fitting well with new tech.

High-speed PCB design has many good points. It helps send data better and stops signal problems. These are important for today’s gadgets to work well. Engineers should use auto wiring solutions to get these benefits. Auto wiring makes designing easier and stops future problems.

"Checking signals is key to making sure connections work right."

In the future, electronics will keep changing, needing better designs. Good simulations will be more important as designs get tighter. By using new tools, industries can stay on top in tech's fast world.

See Also

Improving Automotive Data Transmission with FAKRA PCB Connectors

Boosting Automotive Data Transfer with FAKRA PCB Connectors

Advantages of FAKRA PCB Connectors for Automotive Use

Benefits of FAKRA PCB Connectors for Automotive Purposes

Optimizing Performance with HFM Connectors in Automotive Sector