Why High-Grade Automotive Plugs and Connectors Ensure Driver Safety

Your car's safety relies on its electrical systems working well. Good quality wire connectors automotive type keep these systems running smoothly. They send power to important parts like airbags and brakes. This helps stop problems that could cause accidents. Bad connections can lead to electrical failures and make driving unsafe. Strong, well-made automotive type connectors lower the risk of short circuits or breakdowns. This makes driving safer for you and your passengers.

Key Takeaways

Invest in high-quality automotive connectors to ensure the reliability of critical safety systems like airbags and anti-lock brakes.

Regularly inspect your car's connectors for signs of wear, rust, or damage to prevent electrical failures that could compromise safety.

Choose connectors from trusted brands that meet industry standards and certifications to guarantee durability and performance.

Avoid cheap or counterfeit connectors, as they can lead to dangerous electrical issues and increase the risk of accidents.

Incorporate connector replacement into your vehicle's maintenance routine to maintain optimal performance and safety.

Utilize advanced connector designs, such as HFM systems, to enhance data transmission and save space in modern vehicles.

Stay informed about the materials and engineering of connectors to ensure they can withstand harsh environmental conditions.

The Role of Wire Connectors in Car Safety

Keeping Electrical Systems Reliable

How connectors power airbags and ABS systems

Connectors help send electricity to important car safety parts. They make sure airbags and anti-lock brakes (ABS) work properly. ABS stops wheels from locking when you brake hard, so you stay in control. Airbags pop out quickly during crashes to protect everyone inside. Without good connectors, these systems might not work when needed. Strong connectors keep power flowing, lowering the chance of failure.

Why stable connections are key for modern safety features

New cars have advanced safety tools like lane assist and collision alerts. These tools need steady electrical signals to work right. Loose or weak connections can mess up these signals and cause problems. High-quality connectors stay secure even with bumps or extreme heat. This keeps your car's safety features working well, keeping you safe on the road.

Avoiding Electrical Problems

How bad connections cause short circuits or system issues

Cheap connectors often break easily because they use poor materials. Bad connections can lead to short circuits that harm your car’s systems or start fires. They can also stop important parts like headlights or engines from working right. Good connectors are made tough to handle harsh conditions, reducing failures. Using strong connectors helps prevent electrical problems that could be dangerous.

How electrical trouble affects car performance and safety

Electrical problems don’t just annoy you; they can be unsafe too. A broken system might stall your engine or stop safety features from working right. For example, if brake lights fail, other drivers won’t see you slowing down, which is risky. Quality connectors keep your car running smoothly and safely by avoiding these issues.

Characteristics of High-Quality Automotive Wire Connectors

Durability and Resistance to Environmental Factors

Materials that withstand heat, moisture, and vibration

Car wire connectors deal with tough conditions every day. They face hot weather, freezing cold, and constant shaking on roads. Good connectors use strong materials like special plastics and metal blends. These materials don’t crack or break under pressure. Water, oil, and road salt can also harm connectors over time. Strong connectors have coatings or seals to block these damages. This helps them work well even in bad environments.

The role of corrosion resistance in long-term performance

Rust is a big problem for car connectors. Over time, water and air cause rust that weakens connections. Top-quality connectors use rust-proof materials like stainless steel or coated metals. These stop rust from forming and keep electricity flowing properly. By avoiding rust, these connectors last longer and need fewer replacements.

Precision Engineering and Compatibility

Why proper fit and secure locking mechanisms matter

Connectors must fit perfectly with their matching parts to work well. Loose or wrong-sized connectors can cause poor power flow or failures. Well-made ones are designed to align properly and lock tightly in place. Strong locks stop them from coming apart during bumps or shakes while driving.

The importance of meeting industry standards and certifications

Car wire connectors need to follow strict rules for safety and quality. Certifications like ISO make sure they are strong, reliable, and compatible with cars today. Choosing certified connectors ensures they will work safely with your vehicle’s systems.

Innovations in Connector Design

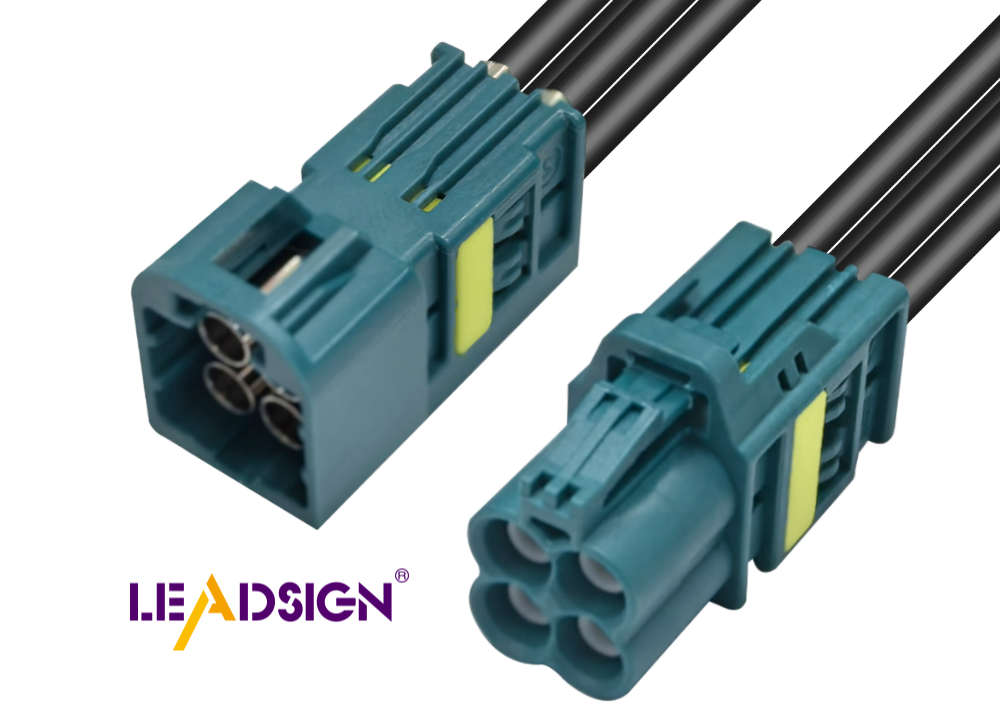

High-speed FAKRA-Mini connectors for modern vehicles

Modern cars use advanced tools like self-driving systems or entertainment screens. High-speed FAKRA-Mini connectors help these tools by sending data very fast—up to 28 Gbps! They are small but powerful enough for tight spaces in cars while still working great.

Benefits of modular systems like HFM for space-saving and high data rates

The HFM connector system is the future of car plugs! Its design saves up to 80% more space than older types—perfect for crowded car areas! It sends data quickly for things like navigation tools or driver alerts while being light and affordable too!

Risks of Using Low-Quality Wire Connectors

More Electrical Failures Likely

Why bad materials wear out fast

Cheap connectors use weak materials that break down quickly. Heat, moisture, and shaking make them weaker over time. This can cause cracks or breaks, stopping electricity from flowing. For example, cheap metals rust faster and create bad connections. Rust increases resistance, which overheats connectors and damages nearby parts.

Studies show bad materials often lead to weak connectors. These weak spots fail under normal car use. Choosing strong connectors avoids these problems and keeps your car safe.

Problems with loose or bad connections

Loose or badly fitted connectors leave gaps in circuits. These gaps cause power loss that affects important systems like headlights. Bad connections also cause arcing, where electricity jumps across gaps. Arcing creates heat that melts wires or connectors.

If connectors don’t lock well, driving vibrations make things worse. This can stop safety features like airbags from working right. Strong connectors with good locks prevent these issues and keep you safe.

Safety Hazards Possible

Fire risks from overheating or short circuits

Weak connectors may not handle heat well or insulate properly. Overheating can start fires by burning nearby materials. Short circuits happen when electricity goes the wrong way due to poor insulation. These shorts can spark fires near flammable parts.

Experts find overheating and short circuits often cause car fires. Tougher, insulated connectors lower these risks a lot. Good-quality ones handle high heat safely and protect passengers from danger.

Failing safety systems like airbags or brake lights

Safety tools need steady electrical flow to work right. Weak connectors fail under stress and stop these tools from working. For example, rusted ones might block airbags during crashes. Broken brake light connections leave drivers behind unaware of your actions.

Your car’s safety depends on reliable wire connectors automotive type ones for tough conditions ensure everything works as it should!

How to Stay Safe by Picking the Right Connectors

Buying from Trusted Brands

Why researching brands and certifications matters

Choosing good wire connectors automotive type starts with trusted brands. Reliable companies use strong materials and smart designs for long-lasting products. They follow strict rules like ISO certifications to meet safety standards. Checking brand reviews and certifications helps you pick connectors that work well in tough conditions.

Tip: Pick brands that test their products carefully. For instance, FORCE Technology checks how connectors handle real-world use. This ensures they stay strong during daily driving without failing.

Avoiding fake or poor-quality products

Cheap or fake connectors might save money at first but are risky. They often break easily because of weak materials, causing electrical problems or dangers. To avoid this, buy from trusted stores or directly from the maker. Reliable sellers provide real products that keep your car's systems safe.

Remember: Good connectors cost more upfront but save money later by lasting longer and needing fewer repairs.

Regular Checks and Maintenance

Looking for damage, rust, or wear

Even top-quality connectors need regular checks to stay in shape. Heat, water, and shaking can cause them to wear out over time. Look for cracks, rust, or loose parts during inspections. Finding these problems early stops them from becoming bigger issues.

Pro Tip: Use a flashlight to check hidden connectors closely. Focus on areas exposed to water or road salt since they rust faster.

Replacing old connectors regularly

Adding connector replacement to your car’s maintenance plan is smart for safety. Swap out worn-out ones or those that don’t fit tightly anymore. Strong automotive-grade connectors last long but replacing them keeps everything working perfectly. This not only protects your car’s systems but also makes driving safer.

Did You Know? Many experts suggest changing connectors during big services like brake fixes. This keeps all parts running smoothly together.

Good car wire connectors are important for safety and reliability. Always pick connectors that follow safety rules and fit your car well. Check them often to find damage early and avoid risks. Changing old connectors during maintenance helps your car work better. Using advanced types like HFM systems improves safety and performance. Choosing strong connectors keeps you and your passengers safe on every trip.

See Also

Boosting Data Transfer: Significance of Fast Automotive Connectors

Crucial Role of HSD Connectors in Automotive Sector

Significance of Fakra Connectors in Today's Vehicles

Improving Automotive Data Flow: Cutting-Edge Connectors and Wires