Powerful Performance: HFM vs Traditional Connectors

In the automotive world, electrical connectors are crucial for optimal vehicle performance. Selecting the appropriate connector is vital for ensuring both efficiency and reliability. Adverse conditions such as wet weather and vibrations can damage connectors, leading to corrosion. Traditional connectors often struggle in these environments. However, the introduction of HFM and Mini-FAKRA electrical connectors addresses these challenges. These innovative connectors offer enhanced durability and performance. By utilizing the right connectors, automakers can significantly improve vehicle functionality, reduce maintenance issues, and enhance system reliability.

Overview of Traditional Connectors

Common Uses

Applications in automotive industry

Traditional connectors are important in cars. They connect different electrical parts. These parts include lights, music systems, and engines. Each part needs connectors to work well. Connectors help power and data move easily between parts.

Typical environments and conditions

Cars face tough conditions for connectors. They run in bad weather. This includes high moisture, harmful gases, and strong shakes. These can make connectors fail. Rust and wear are common problems. Such issues hurt connector reliability.

Benefits

Cost-effectiveness

Traditional connectors are cheap to make. Companies find them good for big productions. Their low price is great for saving money on projects. This makes them popular in many car models. Both makers and buyers save money.

Availability and standardization

These connectors are easy to find everywhere. Standard designs fit many systems well. This makes building cars easier without custom parts needed. Standardization helps with fixing or changing parts too.

Limitations

Performance constraints

Traditional connectors have limits in performance. They might not handle high-speed data well. This affects how fast information moves through them. Newer systems need better performance than they offer.

Durability issues

Durability is a problem for these connectors in cars' harsh places. Wetness and bad gases cause rusting over time, while shaking leads to wear out faster, needing more replacements often.

Limited versatility

They don't fit modern car tech easily due to limited versatility; new car ideas need more flexible solutions that traditional ones can't provide yet.

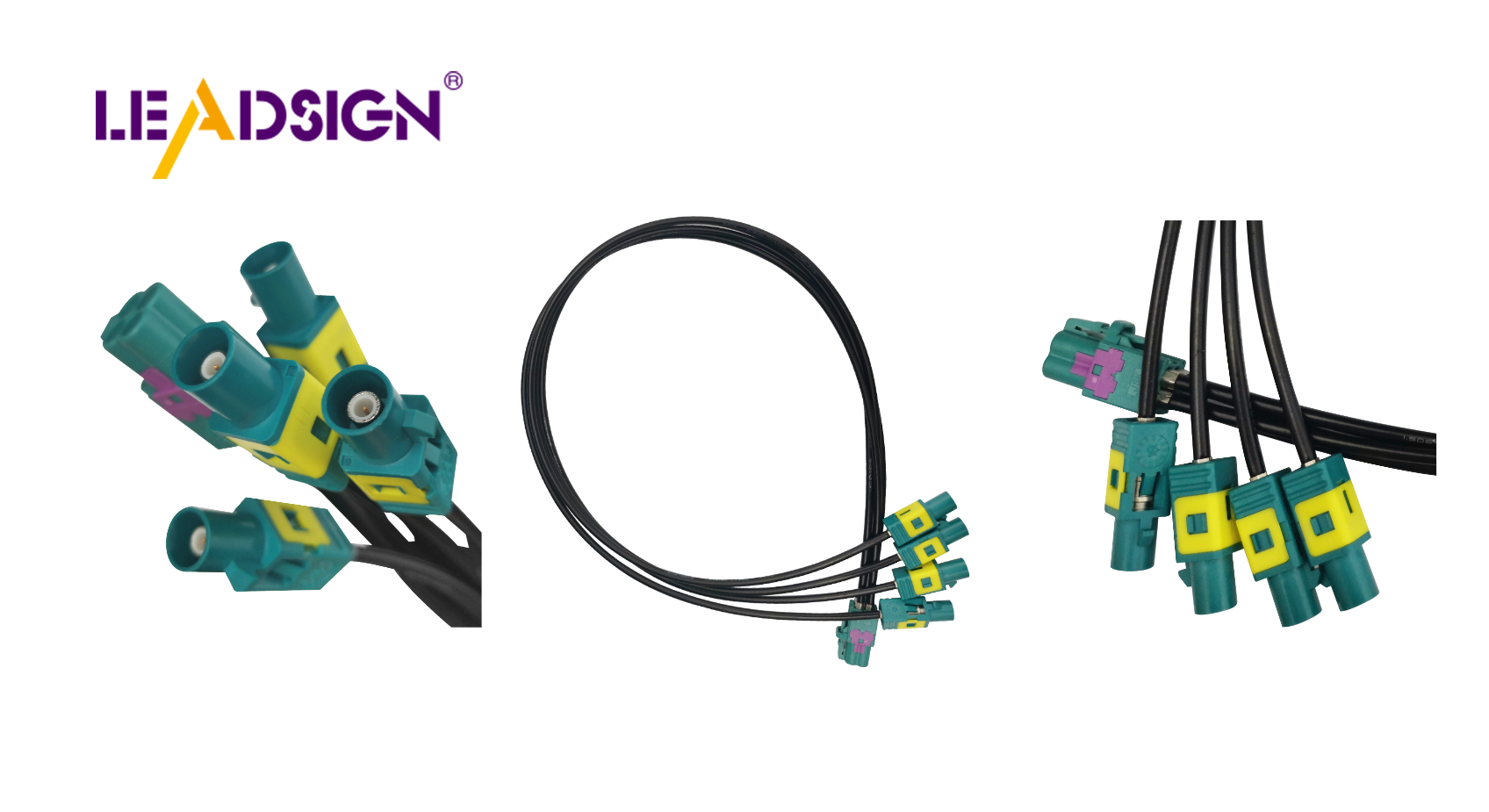

Introduction to Car 50 Ohm FAKRA Z Cable

Advanced Features

The Car 50 Ohm FAKRA Z Cable is great for high-frequency capabilities. It helps send data fast in new cars. Systems like 4K cameras and mobile internet antennas use this feature well. The cable works up to 15 GHz, which is better than traditional connectors that struggle with fast data.

Another important part is enhanced signal integrity. This means clear and reliable communication between car systems. The cable cuts down interference and keeps connections strong. This is important for advanced driver help systems. Traditional connectors often have trouble keeping signal quality, but the FAKRA Z Cable fixes these problems.

Addressing Limitations of Traditional Connectors

The FAKRA Z Cable shows improved performance metrics over old connectors. Old ones can't handle fast data well, but this cable does great here. Its design makes sending data more efficient, helping modern car tech.

It also has increased durability and reliability compared to old connectors that break easily. Things like wetness and shaking hurt them, but the FAKRA Z Cable can handle tough conditions from -40 to 105 degrees Celsius. It lasts long, up to 25 cycles, making it reliable in hard places.

The cable uses new ways to be made too, like 3D printing for better electronic parts. This makes car diagnostic tools work better too. Using LOCTITE 3D IND406 HDT100 High Elongation material makes it even stronger. These upgrades make the FAKRA Z Cable a top pick for new cars.

Comparative Analysis

Performance

Signal transmission efficiency

HFM and Mini-FAKRA connectors are great at sending signals. They help data move quickly between systems. Traditional ones often struggle with this. HFM connectors work well with high frequencies. This makes modern cars function better.

Frequency range and bandwidth

HFM connectors can reach up to 15 GHz. This helps with advanced car systems like cameras and sensors. Traditional ones can't do this. HFM's wide bandwidth allows smooth data flow. This is key for high-tech car uses.

Weight

Impact on vehicle design

HFM connectors make cars lighter. A lighter connector helps car design improve. It boosts vehicle efficiency. Traditional ones add extra weight. Less weight means better fuel use and performance.

Material considerations

HFM connectors use special materials that are strong and light. Traditional ones use heavier stuff. The smart design of HFM makes them last longer. This helps the whole car structure.

Durability

Resistance to environmental factors

HFM connectors handle tough conditions well. They resist water, heat, and shaking. Traditional ones often fail here. HFM's strong build ensures they last long, needing less fixing.

Longevity in automotive applications

HFM connectors last a long time, up to 25 cycles. Traditional ones wear out fast. HFM's durability supports long-term car use, making them a top choice for new vehicles.

Modern car systems need connectors for new tech. HFM connectors work well with high-tech stuff. They help 4K cameras and internet antennas in cars. Old connectors can't do this well. HFM fits perfectly with new car parts, making them great for new cars.

HFM also keeps signals clear between car parts. This is important for driver help systems. Old connectors often mess up signals. HFM fixes this, giving steady performance.

Future car tech will keep changing. HFM can change too. They use smart materials and ways to make them, like 3D printing. This helps them handle heat and weather better, which is good for future cars.

HFM are tough and last long in bad conditions. They are better than old ones at staying strong over time. Car makers trust HFM to keep up with new tech changes.

The FAKRA Z Cable is great for cars. It keeps signals clear and works with fast data. This helps new car tech like 4K cameras and internet antennas. HFM connectors are strong and last in tough places. Use them for future car needs. They change with new tech, so they work well for a long time. Studies show 3D printing makes these connectors better for new ideas. Choose the FAKRA Z Cable and HFM connectors to lead in car technology.

See Also

Enhancing Automotive Efficiency with HFM Connectors

Benefits of HFM Connectors for Automotive Sector

Transforming Auto Connectivity: Benefits of HFM Connectors