A Guide to Wire Connectors Automotive Type

Automotive electrical connectors types are crucial in car systems. They play a vital role in ensuring robust and reliable connections. As automotive technology advances, the demand for various types of connectors increases. The market for automotive electrical connectors types experiences a 5.8% annual growth rate, highlighting their significance in modern vehicles. These connectors are essential for enhancing the performance of new cars by facilitating key connections. Popular types such as cable-to-wire and wire-to-wire connectors dominate the market due to their reliability and efficiency, making them indispensable components in today's automotive industry. They contribute to the continuous improvement of car technology.

Understanding Wire Connectors

Definition and Purpose

What are Wire Connectors?

Wire connectors are key parts in car systems. They link wires to make a safe circuit. This lets power and data move easily in a car. Without them, car wiring would be weak and could fail.

Why are they Important in Automotive Systems?

In cars, wire connectors are crucial. They help devices talk to each other, making sure signals go where needed. This keeps cars safe and systems strong. Connectors also make fixing cars easier for mechanics. As car tech grows, we need better connectors more than ever.

Basic Components

Knowing the main parts of wire connectors helps us see how they work.

Conductors

Conductors are the heart of wire connectors. They move electricity from one spot to another. Made of copper or aluminum, they send electricity well. Their quality affects the whole system's performance.

Insulation

Insulation wraps around conductors for safety. It stops shorts and guards against things like water and heat. Different materials are used, but all keep connections safe.

Terminals

Terminals join the wire to the connector. They give a steady contact point so circuits stay complete. Terminals come in many shapes for different uses, keeping connections firm even when conditions get tough.

Types of Automotive Wire Connectors

Crimp Connectors

Features and Benefits

Crimp connectors are simple and work well in cars. They hold wires by squeezing them tight. This makes a strong link without needing heat or solder. It's fast and easy to set up. These connectors can handle car shakes and bumps, keeping the connection safe.

Common Applications

Crimp connectors are used in many car parts. They are great for places needing a strong link. Mechanics use them for wiring harnesses and battery links. Their easy use makes them popular in cars.

Solder Connectors

Features and Benefits

Solder connectors give a lasting, good connection. They use metal to join wires firmly. This way is very conductive but needs skill to avoid damage from heat. Even so, they are liked for their strength.

Common Applications

Solder connectors are used where a strong link is key. They fit high-performance parts needing good conductivity. Mechanics use them in engine controls and sensors for trustable connections.

Quick Disconnects

Features and Benefits

Quick disconnect connectors are handy in cars. They have locks to stay put during movement. These often stop wires from bending too much or breaking. They let you connect or remove wires easily without losing the connection's strength.

Common Applications

Quick disconnects are used where wires need frequent changes, like lights on cars. They're designed for easy fixes or swaps, making them useful in automotive tasks.

Other Automotive Electrical Connectors Types

Pigtail Connectors

Pigtail connectors are handy in car systems. They link wires to parts, letting electricity flow smoothly. These connectors have a short wire with a connector that joins the main wiring. This setup makes it easy to swap parts without messing up everything else. Pigtail connectors are great when space is tight or for frequent disconnects.

Terminal Blocks

Terminal blocks help organize many wires in cars. They act like a hub, keeping wiring tidy and efficient. By holding wires firmly, terminal blocks stop accidental disconnects and keep connections strong. They're used in complex systems with lots of wires, like control panels. Their design helps with easy fixes and changes.

Bullet Connectors

Bullet connectors offer quick ways to connect or disconnect wires in cars. Their round shape makes them easy to plug in and out, perfect for places needing frequent changes. Bullet connectors are common because they stay connected even if the car shakes or moves. They're often found in lighting systems.

Scotch Locks

Scotch Locks make splicing into existing wires simple without soldering. These connectors pierce wire insulation for a secure link with little effort. Scotch Locks are useful for fast changes, like adding accessories or fixing broken wires. Their ease and reliability make them popular with car techs.

Picking the Best Connector

Choosing the right wire connector for cars is important. It makes sure car electrical systems work well. Here are some things to think about when picking one.

Things to Think About

Power Needs

First, check what power the connector needs. This means knowing how much current and voltage it will handle. Different connectors can take different amounts of electricity. For example, strong systems might need connectors for more current. Matching the connector to power needs stops problems and helps it work better.

Weather Conditions

Weather matters a lot in picking connectors too. Car connectors face tough places like heat, water, and shaking. Pick ones with good covers and seals to stay safe from damage. These keep connections strong for a long time. For example, engine area connectors must handle heat and liquids.

Top Makers

Some companies make great car wire connectors just for your needs.

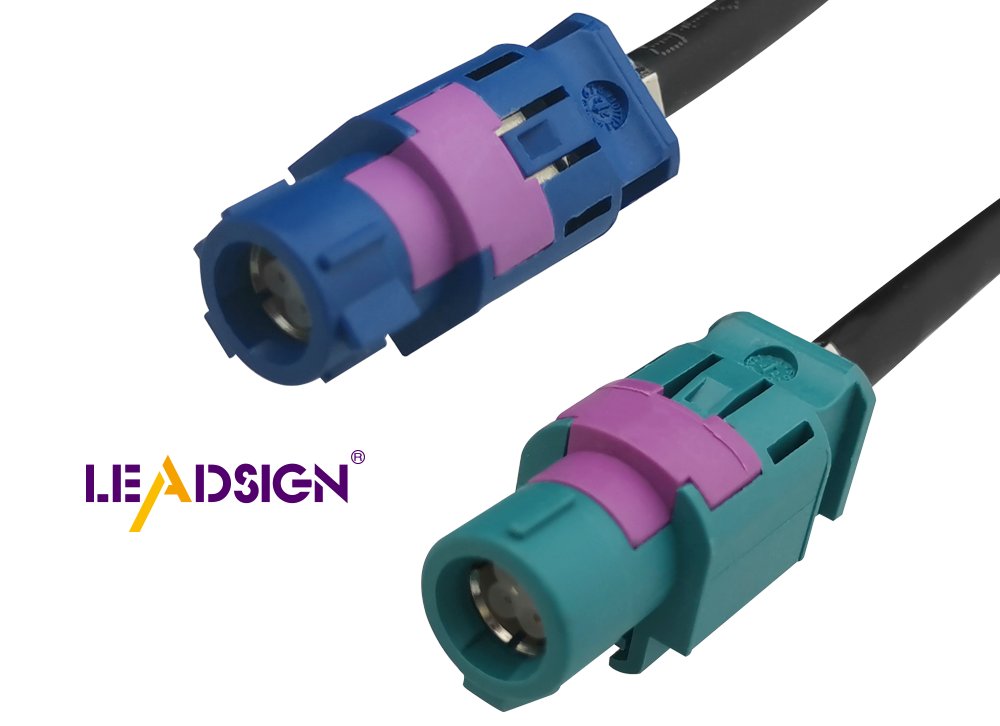

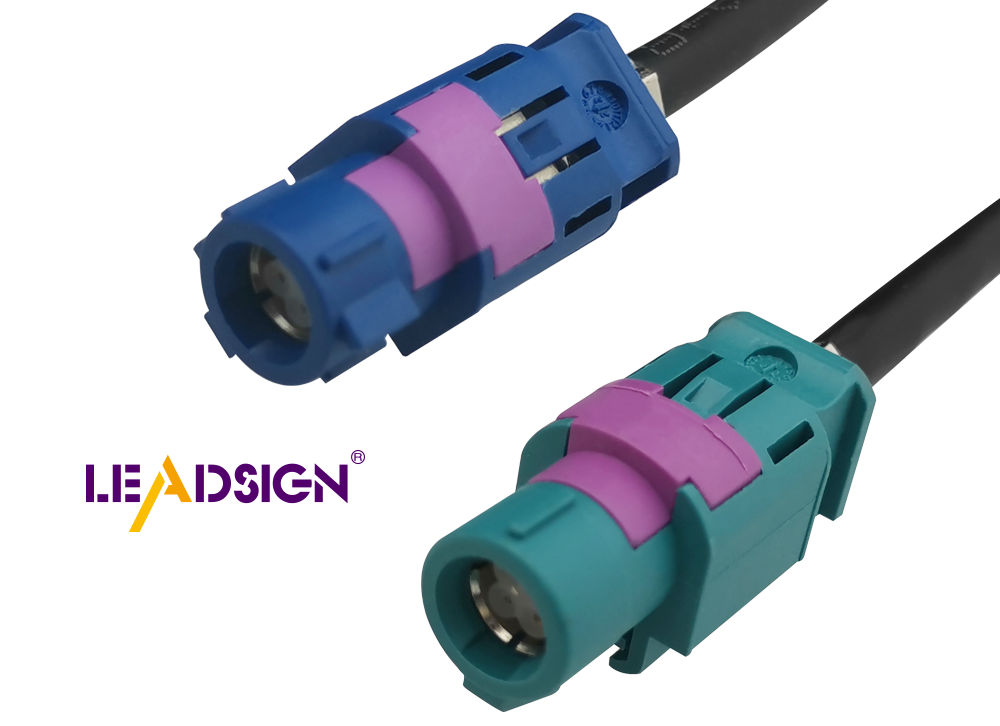

LEADSIGN

LEADSIGN is famous for smart connector ideas. Their High-Speed Data (HSD) ones are special. They help send data fast in cars, like USBs or digital screens. LEADSIGN's locks keep them tight even when it's tough outside.

TE Connectivity

TE Connectivity is another top company making car connectors. They have many kinds that fit different uses. TE focuses on making strong products that last in hard car places. Their parts are used everywhere in cars, from lights to engines, keeping things safe and working well.

Picking the right connector means thinking about power and weather factors carefully. By choosing from trusted makers like LEADSIGN and TE Connectivity, you can trust your car's electrical system will last long and work well.

How to Install Wire Connectors

Installing wire connectors right makes car systems work well. This part shows the tools you need and how to put in wire connectors step by step.

Tools You Need

You need special tools to put in wire connectors safely.

Crimping Tools

Crimping tools are key for crimp connectors. They squeeze the connector and wire together tightly. A good tool makes a strong link that handles shakes and weather. Mechanics like these tools because they make strong connections easily.

Soldering Tools

Soldering tools are important for solder connectors. They use heat to melt metal, joining wires forever. You need a soldering iron and solder wire for this job. These tools make top-quality links, great for parts needing good conductivity.

Step-by-Step Instructions

Following steps helps install wire connectors well so they last long.

Getting the Wire Ready

Strip the Wire: Take off the cover from the end of the wire with a stripper. Make sure the bare part is clean.

Check the Wire: Look for rust or damage signs. Change it if needed for a good link.

Putting on the Connector

Pick the Connector: Choose one that fits your job and wire size.

Place the Wire: Put the bare end into the connector snugly.

Make it Secure:

For crimp ones, use a crimp tool to press it tight.

For solder ones, heat up and add solder to join them firmly.

Testing Your Work

Look at It: Check if there are any loose wires or mistakes.

Test Conductivity: Use a tester to see if electricity flows well with no problems.

Check Strength: Pull gently on it to make sure it's tight.

By doing these steps, you get a safe connection in cars. Brands like LEADSIGN and TE Connectivity have great connectors that boost car safety when used right. Their products handle tough car conditions, making connections last long and work well. Leading brands offer reliable options.

Choosing the right wire connectors for cars is important. They help make sure electrical connections work well and safely. Knowing different connector types and uses helps people pick the best ones for their car.

"Learn useful car knowledge," as noted in guides, shows why it's good to follow proper steps for installing and taking care of connectors. Using correct methods like crimping and soldering keeps connections strong and makes car systems last longer.

See Also

Navigating Ford Fakra Connectors for Automotive Use

Fundamentals of HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses