A Guide to Types of Wire Connectors in Automotive Applications

Wire connectors play a crucial role in automotive systems, facilitating communication between electrical components. Without these connectors, the vehicle's electrical system would fail to function. They ensure safety and optimal performance. There are various types of wire connectors in automotive applications, each serving a specific purpose, such as crimp or solder connectors. Understanding these types highlights the complexity of modern vehicles.

Basics of Wire Connectors

Definition and Function

What are wire connectors?

Wire connectors are important in cars. They join wires to keep connections strong. Think of them as bridges for electricity in a car. Without them, the car's electrical parts might not work right.

How do they function in automotive systems?

In cars, wire connectors help parts talk to each other. When you start your car, they send signals from the key to the engine. They also help with lights and music systems. By keeping connections steady, they make sure everything works well.

Importance in Automotive Applications

Ensuring safety and reliability

Wire connectors keep your car safe and reliable. Good connections stop short circuits that can cause fires. Using quality connectors lowers the chance of problems. This keeps you and passengers safe.

Impact on vehicle performance

Your car's performance depends on its electrical system working well. Wire connectors give power to all parts correctly. This affects how well the engine runs and electronic features respond. As cars get more advanced, better connectors are needed. New things like light wires and fiber cables improve how cars perform today.

Historical Evolution of Wire Connectors

Early Developments

Initial designs and materials

Long ago, car wire connectors were simple but important. They used copper and brass for good electricity flow. These helped early cars work with their small electrical systems. Think of them as the first steps to better car parts.

Evolution in automotive industry

As cars improved, so did wire connectors. Designs became more advanced over time. Engineers tried new materials to make them last longer and work better. This change let cars have safer and more useful electrical systems. It was a time when connectors became key to car progress.

Modern Innovations

Advances in materials and technology

Today’s wire connectors use new materials like strong plastics and metals. They resist heat and rust well in tough car conditions. Technology now makes them very reliable too.

Current trends in automotive connectors

Now, smaller connectors are needed as cars get tinier. Some even have smart tech with sensors for checking things instantly. These changes show how wire connectors keep getting better for today's cars.

Wire connectors in cars come in different types. Each type fits a special need. Knowing these helps you pick the right one for your car.

Crimp connectors are very common in cars. They join wires by squeezing a metal piece around them. You can find them as butt, ring, and spade types. They work well where there is a lot of shaking, like near engines.

Crimp connectors have good points. They hold tight and don’t get loose easily. This makes them great for shaky places. They are easy to put on if you have the right tools. But they can be bad if not done right. Bad crimping makes weak links that might fail.

Solder connectors join wires by melting solder on them. Use them when you need strong connections that last long. They fit well in small spaces since they don't need extra parts.

Solder connectors are very good at letting electricity flow and stay joined forever. But they take more time and skill to use than crimp ones. Heat needed can hurt nearby parts if not careful.

Push-in connectors let you connect wires without tools by pushing them in place. They're good for quick fixes or tight spots.

Push-in connectors are fast and easy to use but may not hold as well as others do over time, especially where it shakes a lot.

Special Connectors

In cars, special connectors are very important. They help with specific tasks and make the car's electrical system work better. Let's look at two main types of wire connectors that car fans often see: FAKRA connectors and Deutsch DT compatible connectors.

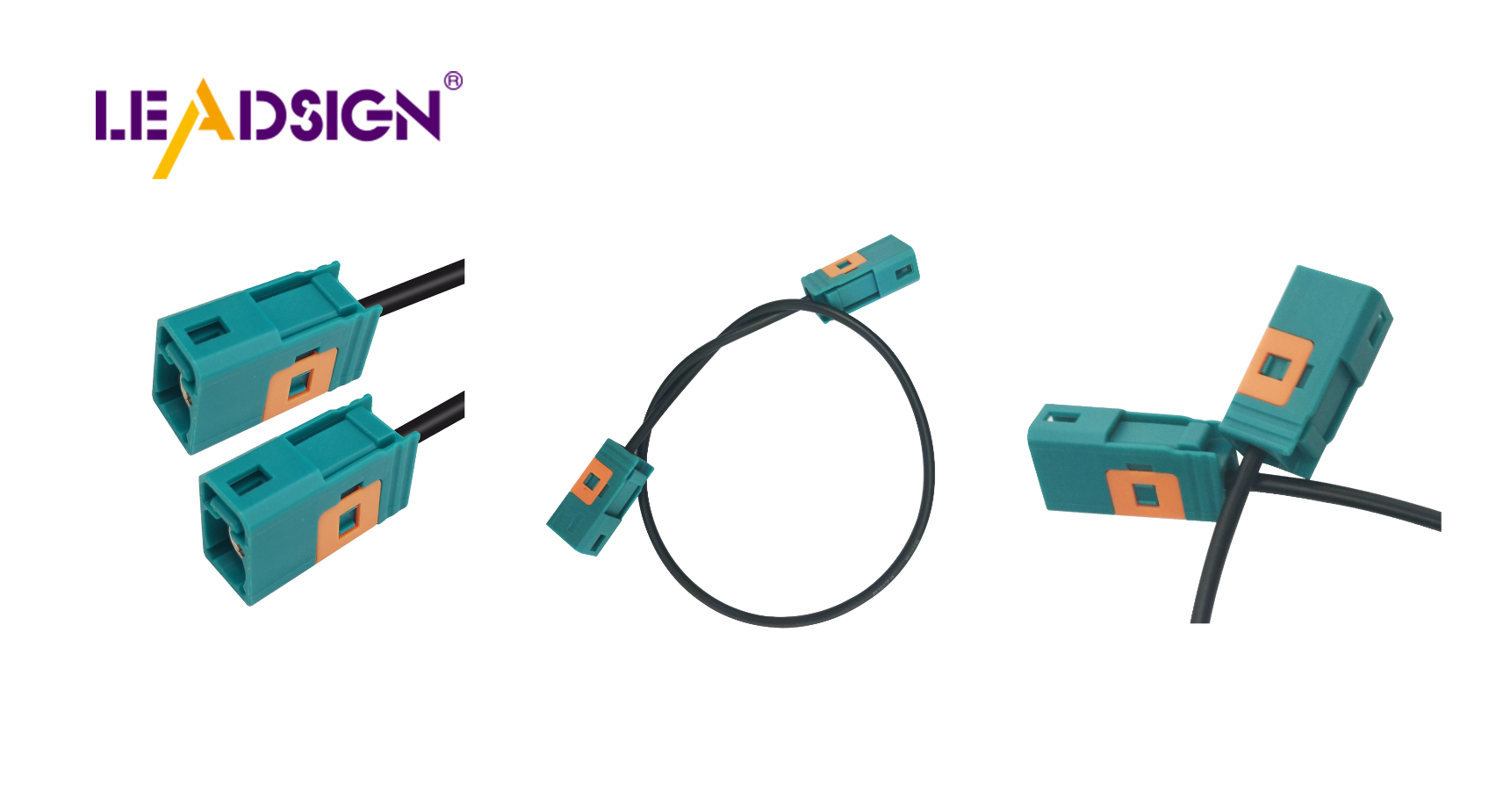

FAKRA Connectors

FAKRA connectors are strong and flexible in cars. You find them in things like GPS, radio antennas, and music systems. They keep connections safe even when conditions are tough.

Main Features of FAKRA Connectors:

Safe Coding System: These connectors stop mistakes with a safe coding system. This makes sure you connect parts correctly.

Strong Assembly Security: With two locking systems, these connectors stay connected well. They work under different conditions without coming loose.

Long-lasting: Made to handle hard car environments, FAKRA connectors are strong and last long. They resist temperature changes and shaking.

"FAKRA connectors meet the hard needs of the car industry, so many makers like them."

Deutsch DT Compatible Connectors

Deutsch DT compatible connectors are also popular in cars. Known for being strong, they do well where reliability is key.

Benefits of Deutsch DT Compatible Connectors:

Changeable Design: These have a changeable design for easy updates. You can quickly change them to fit special needs.

Waterproof and Dustproof: With protection from water and dust, these connectors work well in many car settings.

Easy to Use: The installation is simple. Fixing them is easy too, saving time.

Comparison Insight:

Old copper wires add extra weight to cars, but new light materials used in modern connectors help save fuel.

Modular wiring harnesses with standard parts, like those in Deutsch DT connectors, allow quick changes compared to old custom-made wiring harnesses.

How to Install Wire Connectors

Putting wire connectors in cars needs care and the right tools. This part shows you what tools you need and how to connect wires safely.

Tools You Need

Important Tools for Installation

To put wire connectors on well, use these tools:

Wire Strippers: These take off the plastic cover from wires without breaking them.

Crimping Tool: Use this tool to fasten crimp connectors onto wires.

Soldering Iron: Needed for solder connectors, it melts solder to join wires.

Heat Gun: Good for heat shrink connectors, it makes a waterproof seal.

Multimeter: This checks if the electrical connection works right.

Staying Safe

Safety is very important with car electrical systems. Follow these rules:

Unplug the Battery: Always unplug the car battery first to avoid shocks.

Wear Safety Gear: Put on gloves and safety glasses for protection.

Work in Bright Light: Make sure you have enough light to see clearly.

Stay Dry: Work in a dry place to stop accidents.

Steps to Follow

Getting Wires Ready

Cut Wires: Use cutters to make wires the length you want.

Strip Cover Off Wires: Take off about half an inch of cover using strippers.

Twist Wire Ends Together: Twist bare wire ends together so they connect easily.

Joining Wires Together

Pick Connector Type: Choose crimp or solder connectors that fit your job.

Put on Connector:

For Crimp Connectors: Put wire in connector and squeeze with crimp tool.

For Solder Connectors: Hold wires together, melt solder with iron, let cool down.

For Push-in Connectors: Push wire into connector until it clicks.

Checking Connection

Plug Battery Back In: After connecting, plug car battery back in place.

Use Multimeter: Test connection with multimeter; ensure no resistance exists.

Look Closely: Check for loose parts; make sure everything stays tight.

By doing these steps, your wire connections will be done right and work well in your car's system.

Q&A: Common Issues and Maintenance

Fixing Usual Problems

Finding Bad Connections

If your car's lights flicker, check the wires. Look at connectors for rust or loose parts. Use a multimeter to test them. If it shows high resistance, the connection is bad.

Fixing Common Problems

After finding a bad connection, clean it first. Use a cleaner to remove dirt. If broken, get a new connector. Pick the right type for your car. Crimp or solder it well to stop future problems. Test with a multimeter again to make sure it's fixed.

Care Tips

Regular Checks and Cleaning

Check your car's wires often. Look for damage every few months. Clean them with a contact cleaner to stop rust.

Keeping Them Working Well

Use good connectors that last long in tough places. Follow instructions when putting them on to avoid mistakes. Keep them dry and use waterproof ones if needed. Test connections regularly with a multimeter to find issues early.

By doing this, your car's electrical system stays strong and works better.

Picking the right wire connectors is very important for your car's safety and how well it works. By choosing the right ones, you make sure that the electrical connections stay strong even in tough conditions. Always do things the best way when putting them on and taking care of them. Checking them often and taking good care helps them last longer.

"The future of wire connectors in cars looks bright with new technology and materials."

Keep learning about new changes to keep your car's electrical system working well and up-to-date.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive: A Beginner's Guide

Significance of FAKRA Connectors in Automotive Implementations