A Guide to Types of Wire Connectors Automotive

Wire connectors play a crucial role in automotive systems, ensuring the efficient operation of your car's electrical components. These types of wire connectors automotive are designed to keep your vehicle's wiring secure and reliable. Different types of wire connectors are used for various applications, ensuring strong and safe connections. Understanding the types of wire connectors automotive helps you make informed choices. These connectors prevent electrical issues, enhancing the reliability of your car. Selecting the appropriate wire connectors makes your vehicle more dependable.

Basics of Wire Connectors

Definition and Purpose

What are wire connectors?

Wire connectors are tiny tools that link wires together. They keep wires connected safely in cars. You use them to stop wires from getting loose or causing problems. These connectors come in different shapes and sizes for specific uses. Using the right wire connectors helps keep your car's electrical system working well.

Why are they essential in automotive systems?

Wire connectors are important because they make sure connections stay strong. They help avoid electrical problems that can cause car issues. Picking the right wire connectors makes sure your car parts work well. This is important for safety and how well your car runs. Good connectors also protect against things like water and shaking, which can harm wires over time.

Historical Evolution

Early developments in wire connectors

Long ago, people twisted wires to connect them in cars. This was not very safe and often failed. As cars got more complicated, better connections were needed. Early wire connectors were simple but worked better than twisting wires together. They made joining wires safer, lowering the chance of problems.

Modern advancements and innovations

Today’s wire connectors have improved a lot. New ones last longer and are easier to use. Some can handle tough conditions like heat or wetness. Better materials and designs make them conduct electricity well and protect better too. Special new types of wire connectors help cars work better overall, making them safer and perform better.

Types of Wire Connectors Automotive

Knowing different wire connectors is key for your car's electrical system. Each type has a job and offers special help. Let's look at some common ones.

Crimp Connectors

Crimp connectors are liked in cars because they work well and are easy to use. They come in many shapes, each for a different job.

Types of crimp connectors

Butt Connectors: Join two wires end-to-end. Great for making wires longer.

Ring Connectors: Have a ring end that fits over bolts or screws. They hold tight.

Spade Connectors: Look like forks, making it easy to attach and remove from terminals.

Uses in car systems

Crimp connectors can do many things. Use them with batteries, lights, and sound systems. Their design keeps connections strong so wires don't come loose.

Solder Connectors

Solder connectors make lasting wire links. Heat melts solder to join wires together.

Good and bad points

Good Points:

Strong Link: Soldering makes a tough bond.

Great Conductivity: It lets electricity flow well.

Bad Points:

Needs Skill: You must practice to solder right.

Takes Time: It's slower than crimping.

Common uses in cars

Solder connectors are used where links need to last forever. They're found in engines and places with lots of shaking.

Push-In Connectors

Push-in connectors make connecting simple. Push the wire in, and it locks tight.

How they work

Push-in connectors have springs inside. When you push the wire, the spring grabs it tight without needing tools.

Best places to use them

These work best where there's little shaking, like dashboards or inside lights. They're quick to install and work well.

By knowing these types of wire connectors automotive, you choose wisely for your car's electric needs. Each type is strong, giving you the right tool for every task.

Other Connector Types

Knowing about different wire connectors helps you fix your car's wires. Each type of connector has a special job to keep connections safe and working well.

Pigtail Connectors

Pigtail connectors make joining many wires easy. Twist the wires together, then cover with a cap. This makes sure they stay connected and don't come loose. Use them when connecting lots of wires in one spot, like car lights or adding new gadgets.

Bullet Connectors

Bullet connectors join two wires quickly and safely. They have a male and female part that fit tightly. You can take them apart easily if needed, which is good for places where you change or fix things often. They're used in car lights and speakers for strong but flexible links.

Sealed Automotive Electrical Connectors

Sealed connectors keep water and dirt away from connections. They have rubber seals to block out bad stuff. Use them in tough spots like under the hood or outside areas. Sealed connectors stop rust, keeping your car's wiring safe.

By learning about these wire connectors, you pick the right ones for each job. Each kind helps keep your car's electrical system strong and working well.

How to Install Wire Connectors

Tools You Need

Important tools for installing

To put wire connectors in your car, you need the right tools. These tools help you do it safely and correctly. Here’s a list of important tools:

Wire Strippers: Take off the plastic cover from wires without breaking them.

Crimping Tool: This tool helps you attach crimp connectors tightly.

Soldering Iron: Use this for solder connectors to make strong links.

Heat Gun: This tool is good for heat shrink connectors, adding extra safety.

Multimeter: Check if electrical connections work well with this tool.

Having these tools makes installation easier and faster.

Safety tips

Safety is very important when working with car wires. Follow these tips to stay safe:

Disconnect the Battery: Always unplug the car battery before starting any wire work. This stops shocks or short circuits.

Wear Safety Gear: Use gloves and glasses to protect your hands and eyes from sharp wires and sparks.

Work in Bright Light: Good light helps you see better, lowering mistakes.

Stay Dry: Water and electricity don’t mix. Keep your workspace dry to avoid accidents.

By following these tips, you keep yourself safe.

Steps to Install

Getting wires ready

Getting wires ready is key for success. Follow these steps:

Cut the Wires: Use cutters to make wires the right length.

Strip Insulation: Take off about half an inch of cover from wire ends using strippers.

Twist Wire Strands: Twist bare wire strands together so they stay neat.

These steps get your wires ready for a strong link.

Connecting wires well

Once wires are ready, connect them like this:

Pick Right Connector: Choose the right connector type for what you need.

Put Wires In Connector: Place stripped wire ends into connector holes.

Secure Connection: Use a crimping tool or solder iron based on connector type to secure it tight.

Check Connection: Use a multimeter to test connection works fine.

By doing these steps, you make strong connections in your car's system.

Common Problems

Fixing Bad Connections

If your car's wires aren't working, fix them fast. First, check for loose wires. Gently pull each wire to see if it's loose. If a wire is loose, use the right connector to fix it. Next, look at the connectors. See if they are rusty or broken because that stops electricity. Change any bad connectors to make them work again. Finally, use a multimeter to test if electricity flows right.

Spotting Wear and Tear

Check your car's wires often to find problems early. Look for worn or bare wires that can cause shorts. Check connectors for cracks or color changes that mean trouble. Notice any weird smells like burning plastic; it might mean overheating. If you see these signs, fix them quickly to stop more damage.

Maintenance Tips

Regular Checks

Make a habit of checking your car's wires often. Try every few months. Look at all the wires and connectors you can see with a flashlight in hard spots. Make sure everything is tight and safe. If you find issues, fix them right away.

Keeping Wires Lasting Long

To keep your car's wires lasting long, follow these tips: Don't overload circuits; use the right wire size so they don't overheat or break. Protect wires from things like water by using covers like heat shrink tubes or conduits. Keep connections clean and rust-free by using special grease on them.

Picking the right wire connectors is important for your car's electric system. The right ones keep it safe and working well, stopping problems before they start. Knowing about different types helps you choose better, making your car work better too. Use this knowledge to take care of your car properly. Check often and install correctly to keep it running smoothly. A good electric system helps your whole car stay healthy. Be active in caring for your car, and enjoy driving safely and reliably.

See Also

A Comprehensive Ford Fakra Connector Guide

Essential HSD Connectors in Automotive Sector

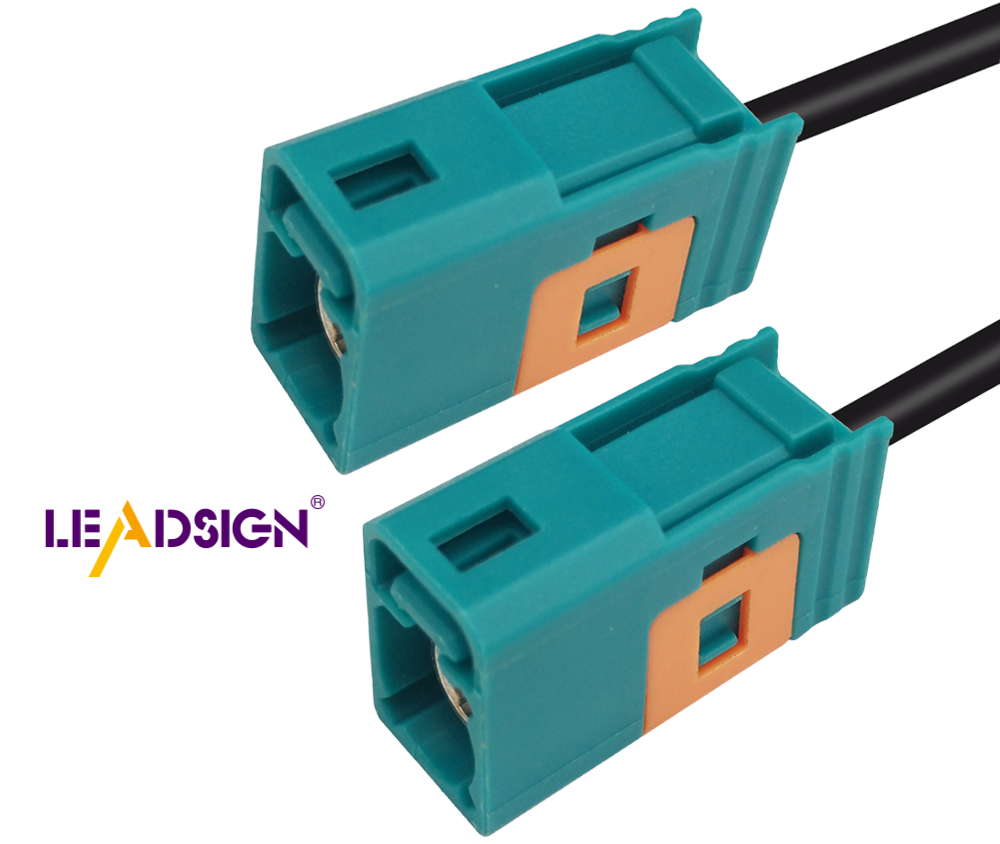

Significance of FAKRA Connectors in Auto Uses