A Complete Guide to Automotive Plugs and Connectors for Every Application

Vehicle connectors are crucial for ensuring safe and reliable electrical links in your car. They are key components of your vehicle's electrical system, controlling power and signals between different parts. Choosing the right connector, such as for the battery, can be challenging due to the variety of types available. OEM vehicle connectors comply with industry standards and help maintain system performance. They provide strong and durable connections. Without quality vehicle connectors, factors like water exposure and vibrations can compromise your car's safety and performance.

Key Takeaways

Vehicle connectors are essential for maintaining safe and reliable electrical systems in cars, preventing power loss and signal issues.

Choosing the right type of connector, such as blade, ring, or specialty connectors, is crucial for specific applications like battery connections and engine components.

Opt for OEM connectors to ensure compatibility and compliance with industry standards, enhancing the performance and safety of your vehicle.

Regularly check and clean your connectors to prevent rust and dirt buildup, which can lead to electrical failures.

Use dielectric grease on connectors to protect against moisture and corrosion, extending their lifespan and reliability.

Follow proper installation steps, including using the right tools and testing connections, to ensure strong and lasting electrical links.

Understanding the specific electrical needs and environmental conditions of your vehicle will help you select the best connectors for optimal performance.

Understanding Vehicle Connectors

What Are Vehicle Connectors?

Vehicle connectors are important parts of your car's electrical system. They connect circuits to allow power and signals to flow smoothly. These connectors come in different shapes and sizes for specific uses. For example, high-current connectors have bigger pins for better contact and performance.

You can see vehicle connectors in many areas of your car. Some examples are connectors in wiring harnesses that link headlights, sensors, and infotainment systems. Automotive electrical connectors also connect the engine control unit (ECU) to other systems, helping them work together properly.

Why Are Vehicle Connectors Essential?

Keeping Electrical Systems Safe and Reliable

Vehicle connectors are needed to keep your car's electrical systems safe and working well. They make strong connections to stop power loss or signal problems. For instance, battery terminal connectors link the battery to the car's electrical system securely. Without these, your car might not work well and could become unsafe.

Avoiding Problems and Improving Performance

Good connectors stop problems caused by heat, water, or vibrations. Many are made from strong materials like copper or brass to avoid rust and last longer. Using strong connectors can make your car run better and lower the chance of electrical troubles.

Types of Vehicle Connectors and Their Uses

Blade Connectors

Features and Benefits

Blade connectors are very common in cars. They have a flat metal piece that fits into a slot. This creates a strong and steady connection. These connectors are simple to use and easy to replace. They are great for parts that need regular fixing or changing. Their design keeps them tight, stopping loose connections that may cause problems.

Blade connectors are also flexible. They come in different sizes and materials. Many are made from metals that don’t rust, so they last longer. This makes them a smart choice for keeping your car’s electrical system working well.

Uses in Lights and Fuse Boxes

Blade connectors are often used in lights and fuse boxes. They connect headlights, taillights, and inside lights securely. In fuse boxes, they help power flow safely to protect circuits. Their simple design makes fixing and replacing them quick and easy.

Ring Connectors

Features and Advantages

Ring connectors have a round end that fits around a bolt. This design makes them strong and hard to disconnect. They are perfect for parts that need to stay connected even with movement. The ring shape keeps them secure, even if the car shakes.

These connectors come in different sizes and materials like copper and brass. These materials don’t rust and carry electricity well. They are built to last, even in tough conditions. Ring connectors are dependable for important car parts.

Uses in Batteries and Grounding

Ring connectors are often used in batteries and grounding systems. They connect the battery to the car’s electrical system safely. In grounding, they stop electrical problems by giving extra current a safe path. Their strength makes them key for keeping your car running well.

Specialty Connectors

Examples Like Waterproof and Heat-Resistant Connectors

Specialty connectors are made for special jobs in cars. Waterproof connectors keep water out, so they work well in wet areas. Heat-resistant connectors handle high heat, making them good for engine areas.

These connectors often have seals and strong materials to work better. Picking the right specialty connector can solve tricky problems in your car’s electrical system.

Uses in Engine Parts and Sensors

Specialty connectors are important for engines and sensors. Waterproof ones protect sensors in wet places like exhaust systems. Heat-resistant ones keep engine control units connected in hot areas. These connectors help your car’s main systems work smoothly and reliably.

Multi-Pin Connectors

Features and Configurations

Multi-pin connectors link many wires in one place. They have several pins to send power and signals together. Their small size saves space and keeps things neat. These connectors come in shapes like rectangles or circles for different uses.

The best thing about multi-pin connectors is their ability to handle complex systems. They often have locks to stop them from coming loose. Many are made from strong materials like rust-proof metals and tough plastics. This helps them survive heat, shaking, and other tough conditions.

Uses in Systems Like ECU and Infotainment

Multi-pin connectors are important for advanced car systems. They are used in the Engine Control Unit (ECU) to connect sensors and parts for smooth engine work. They also link screens, speakers, and controls in infotainment systems. Their ability to handle many wires makes them very useful.

These connectors are also key in safety systems like airbags and anti-lock brakes (ABS). They make sure these parts work without stopping, keeping your car safe and running well.

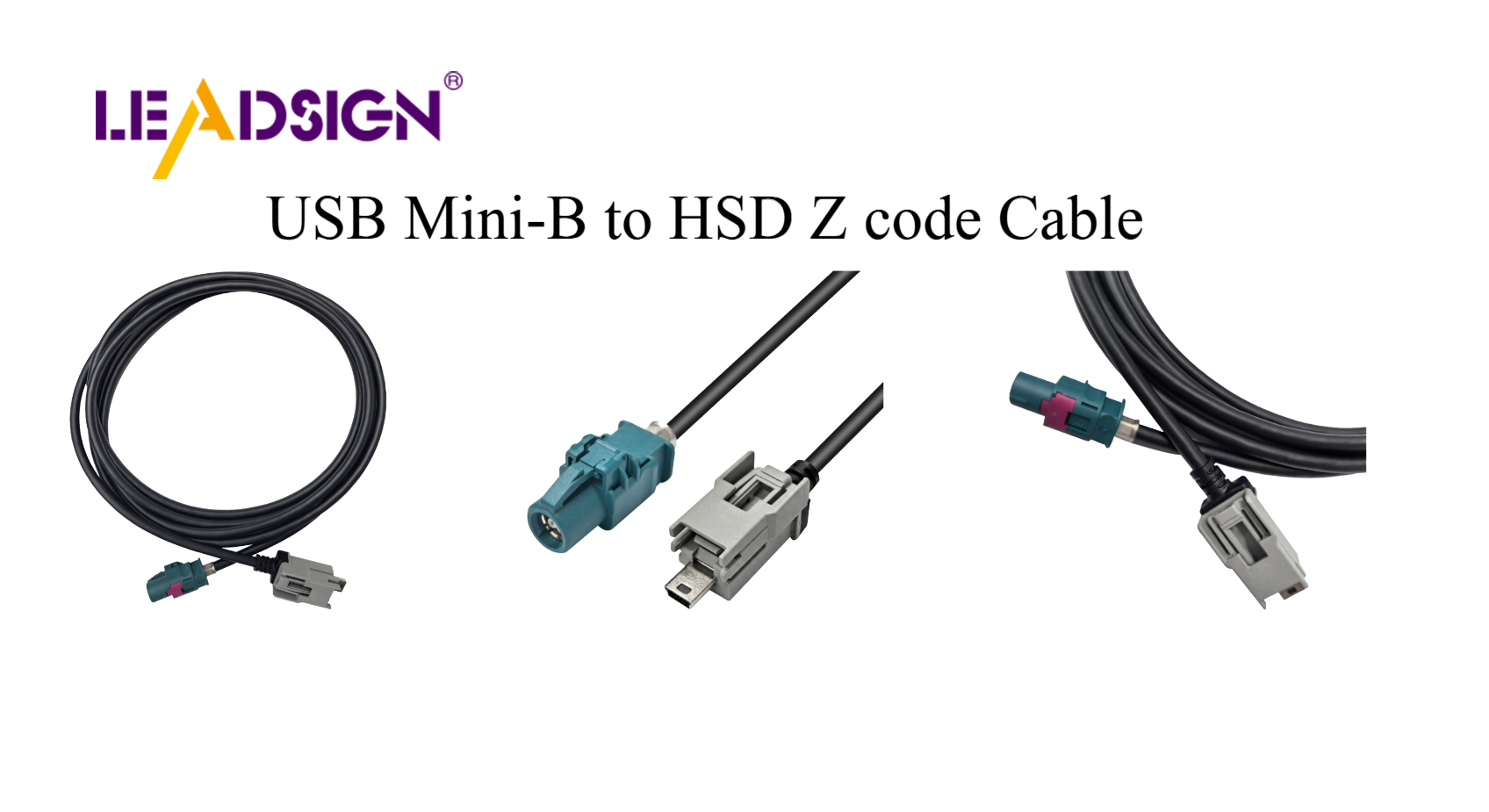

High-Speed Data (HSD) Connectors

What HSD Connectors Do and How They Work

High-Speed Data (HSD) connectors send data quickly in cars. They are great for fast and steady data transfer in electronics. They have locks to keep them secure and crimp designs to hold cables tightly. This stops them from coming loose.

HSD connectors are also smartly designed. Different markings on them prevent wrong connections. Their strong build helps them handle heat and shaking without breaking.

Uses in Car Electronics, USB, and Ethernet

HSD connectors are used in car electronics for fast data sharing. They connect cameras, sensors, and control units for features like parking help and driver assistance. They also link USB devices like phones and music players.

Besides USB, HSD connectors are vital for Ethernet in cars. They help systems like navigation and infotainment talk to each other quickly. They are also used in wireless networks, making them a big part of modern car tech.

Key Things to Think About When Picking Battery Terminal Connectors

When picking battery terminal connectors or other vehicle connectors, focus on key points. These help ensure good connections, proper fit, and lasting performance.

Electrical Needs

Voltage and Current Limits

Know the voltage and current limits of a connector. Each one is made for certain electrical loads. Using the wrong one can cause overheating or failure. For example, battery terminal connectors must handle high current to start your car. Always check if the connector fits your car's needs.

Matching OEM Automotive Connectors

Make sure the connector matches your car's OEM system. OEM automotive connectors meet standards and fit well with your car's wiring. Pick connectors that work with oem wiring connectors to avoid problems or mismatched parts.

Tough Conditions

Handling Heat, Water, and Vibrations

Cars face tough conditions, so connectors must be strong. Choose ones that resist heat, water, and shaking. Waterproof or heat-resistant connectors are great for wet or hot areas like engines. This keeps connections safe in harsh places.

Long-Lasting Materials

Strong materials make connectors last longer. Metals that resist rust, like copper or brass, work well. Battery terminal connectors made from these materials stay reliable in tough environments.

Safety Rules and Certifications

Following Safety Standards

Safety is important when choosing connectors. Pick ones that follow industry rules. Certified connectors are tested for safety and reliability. For example, ISO or SAE-certified connectors lower the chance of failures.

Certifications to Check

Look for certifications like UL or CE. These show the connector meets strict safety and quality checks. Certified connectors keep your car's electrical system safe and working well.

By thinking about these points, you can pick the best types of battery terminal connectors and other connectors. Focus on quality and durability and ensure they match oem systems to keep your car safe and running smoothly.

Material and Build

Why Rust-Free Materials Matter

Rust-free materials are key for keeping your car working well. Choosing connectors made of copper or brass helps stop rust. These materials keep electricity flowing smoothly, even in tough places. For example, battery terminal connectors made from rust-free metals keep the battery linked to the car. This strong link stops power issues and boosts performance.

Modern car connectors, like oem wiring connectors, often have coatings or seals. These protect against water, dirt, and road salt. Such features are useful in wet or dirty areas. Picking connectors with these traits makes your car parts last longer and need fewer fixes.

Staying Strong in Tough Conditions

How a connector is built affects how it handles stress. Good connectors can take heat, shaking, and other car stresses. For example, types of battery terminal connectors must handle engine heat while staying secure. Strong materials like stainless steel or tough plastics make them last longer.

The design also matters for strength. Crimp connections and locks keep connectors tight, even with movement. This is vital for systems like infotainment or engine controls, where steady links are needed.

Choosing connectors with strong builds and rust-free materials improves your car's quality and durability. This choice helps your car work better and avoids expensive repairs later.

A Simple Guide to Installing and Caring for Car Wiring Connectors

Installing and taking care of car wiring connectors keeps your car's electrical system working well. This guide gives easy steps and tips to make strong connections and avoid problems.

How to Install Connectors

Tools You’ll Need

Before you start, gather these tools to make the job easier:

Wire strippers to remove the plastic cover from wires.

Crimping tools to attach connectors tightly.

Screwdrivers to tighten screws on some connectors.

Heat shrink tubing or tape to cover connections.

A multimeter to check if the connection works.

Having these tools ready helps you finish without stopping.

Steps to Install Connectors

Follow these simple steps to install car wiring connectors:

Get the Wires Ready: Use a wire stripper to remove the plastic cover from the wire ends. Make sure the bare wire length matches the connector size.

Pick the Right Connector: Choose a connector that fits the wire size and works for your car's electrical needs. For example, battery terminal connectors must handle high power.

Attach the Connector: Put the bare wire into the connector. Use a crimping tool to secure it tightly. Check that no wire strands are sticking out.

Cover the Connection: Slide heat shrink tubing over the connection or wrap it with tape. If using heat shrink, heat it to make it fit snugly.

Check the Connection: Use a multimeter to test if the connection is secure and working.

These steps help you make a strong and lasting connection.

Tips for Taking Care of Connectors

Check and Clean Regularly

Look at your connectors often to spot problems early. Check for rust, dirt, or loose wires. Clean them with a soft brush or cloth. For tough dirt, use a special cleaner for electrical parts.

Stop Rust and Wear

Rust can weaken connections and cause problems. To stop this, put dielectric grease on the connectors. This grease keeps out water and dirt. Also, seal connectors well, especially in wet or hot areas.

Fixing Common Problems

Loose or Bad Connections

Loose or bad connections can cause electrical issues. Gently pull on wires to see if they move. If a connector is loose, re-crimp or tighten it. Replace broken connectors right away to fix the problem.

Changing Broken Connectors

To replace a broken connector, follow these steps:

Turn off the power to stay safe.

Cut off the broken connector close to the wire base.

Strip the wire and attach a new connector using the earlier steps.

Test the new connection to make sure it works.

Fixing broken connectors quickly keeps your car's electrical system safe and working well.

By caring for your car wiring connectors and fixing problems fast, you can keep your car's electrical parts safe and reliable.

Picking the right car connectors is very important. It helps keep your car safe and working well. This guide explains key points to think about. Make sure connectors match your car's system and handle tough conditions. Strong materials that resist rust are a smart choice. Focus on these tips to make good decisions. Whether it's a battery connector or another type, choose secure designs. Use this guide to find the best connectors for your car. This will help your car stay reliable and run smoothly.

FAQ

What does a vehicle connector do?

A vehicle connector joins electrical parts in your car. It lets power and signals move between systems like lights, sensors, and radios. Without it, these systems might stop working or work poorly.

Why pick OEM wiring connectors?

OEM wiring connectors fit your car’s system perfectly. They are easy to install and very reliable. Using them keeps your car running safely and as it should.

How often should you check your car’s connectors?

Check your car’s connectors every three to six months. Regular checks find rust, dirt, or loose wires early. This stops bigger problems and keeps your car working well.

What tools are needed to install connectors?

You need wire strippers, crimping tools, screwdrivers, heat shrink tubing, and a multimeter. These tools help make strong and lasting connections.

How can you stop connectors from rusting?

Use dielectric grease to keep out water and dirt. Waterproof connectors are best for wet areas. Clean them often to avoid rust and make them last longer.

What shows a connector is bad?

A bad connector may cause flickering lights or broken sensors. Power might cut off sometimes. Loose wires or rust are also signs. Fix these problems quickly to avoid damage.

Can one connector work for everything?

No, different jobs need different connectors. Batteries need high-current connectors. Wet areas need waterproof ones. Always pick the right connector for the job.

How do you fix a broken connector?

Turn off the power first. Cut off the broken connector and strip the wire. Attach a new one with a crimping tool. Test it with a multimeter to make sure it works.

Why care for connectors?

Taking care of connectors makes them last longer. Clean and check them often. Use the right connectors to stop overheating or breaking. This keeps your car safe and working well.

How do mechanics use external connectors?

Mechanics use external connectors to check your car’s health. They connect tools to your car through these connectors. This helps them find problems and suggest fixes.

See Also

Exploring Ford Fakra Connectors: A Complete Overview

A Detailed Look at the Fakra Plug Explained

Fundamentals of HSD Connectors in Automotive Applications