A Guide to Types of Wire Connectors Automotive

Automotive wiring connector types are crucial in vehicles. They play a vital role in ensuring the safety and optimal functioning of the car's electrical system. These connectors safeguard the vehicle and contribute to its smooth operation. With various automotive wiring connector types available, understanding them is essential for maintenance and repairs. This knowledge enables selecting the appropriate connector to maintain the safety and efficiency of vehicles.

Basics of Wire Connectors

Definition and Purpose

What are wire connectors?

Wire connectors are important parts in cars. They join wires tightly so they don't come loose. This helps stop electrical problems. By holding wires firmly, they keep electricity moving smoothly in the car.

Why are they essential in automotive systems?

In cars, wire connectors are very important. They help keep cars safe and working well. Without them, electric systems might break and cause danger. Connectors make sure electricity moves safely and correctly. This is crucial for how well the car works and stays safe.

Materials and Design

Common materials used

Different materials make wire connectors. Plastic and metal are common ones. Plastic stops shocks by insulating wires. Metal like copper or aluminum helps electricity flow well. These materials make sure connectors last long in cars.

Design considerations for automotive use

Making wire connectors for cars needs careful planning. Connectors need crimping areas to cover copper inside from showing. Locks keep wires connected even if there's shaking. These features help the car's electric system work safely and properly.

Historical Evolution of Wire Connectors

Early Developments

Initial designs and uses

Wire connectors have been important in cars for a long time. At first, they were simple tools to keep wires together. The main goal was to stop wires from coming apart. These connectors helped avoid electrical problems that could be dangerous. By keeping connections steady, they made cars safer and work better.

Evolution over time

As time passed, wire connectors changed a lot. Engineers used new materials and designs to make them better. Insulated crimping areas were a big improvement. They stopped insulation from shrinking, which reduced short circuits or electrical dangers. This also helped control how wires moved with the connector, making connections stronger. As technology grew, wire connectors got more advanced for complex car systems.

Modern Innovations

Technological advancements

Today’s wire connectors are very advanced. Engineers made them with locking parts for good signal flow. This keeps the car's electric parts working well together. Fast data connectors are used in digital systems now too. They help send lots of data quickly inside the car's electronics.

Impact on automotive industry

These new ideas have greatly changed cars today. Modern wire connectors make cars safer and work better with features like digital screens and fast data sharing. They help cars be more reliable and efficient by making sure electric systems run well. Because of this, the car industry keeps improving with safer and smarter vehicles.

Automotive Wiring Connector Types

Knowing the different car wire connectors is important. Each connector type has a special job and helps keep the car's electric system safe and working well.

Crimp Connectors

Features and benefits

Crimp connectors are popular in cars because they work well and are easy to use. They have a part that locks wires, keeping signals strong. The insulated area stops short circuits and electrical problems. A locking part keeps wires connected even if there's shaking.

Common applications

Crimp connectors are used in many car parts. They connect wires in engines, lights, and other places needing strong connections. They can handle tough conditions, so many car experts like them.

Solder Connectors

Features and benefits

Solder connectors join wires by melting solder for a strong connection. This gives great signal flow with low resistance, good for high-performance cars. They resist rust and weather, making them last long.

Common applications

Solder connectors are used where connections must stay forever. They're found in engine controls and sensors where reliability matters most. Their strength makes them good for shaky places.

Push-In Connectors

Features and benefits

Push-in connectors let you connect wires fast without tools. You just push the wire in to lock it easily. These connectors hold tight but can be undone quickly too, making them very useful.

Common applications

Push-in connectors are used when quick setup or removal is needed in cars. They're great for temporary setups or places needing regular checks like dashboards or gadgets. Their simple design is liked by pros and DIY fans alike.

Specialty Connectors

Specialty connectors in cars meet special needs. They help cars work well and stay safe. These connectors solve problems that regular ones can't fix.

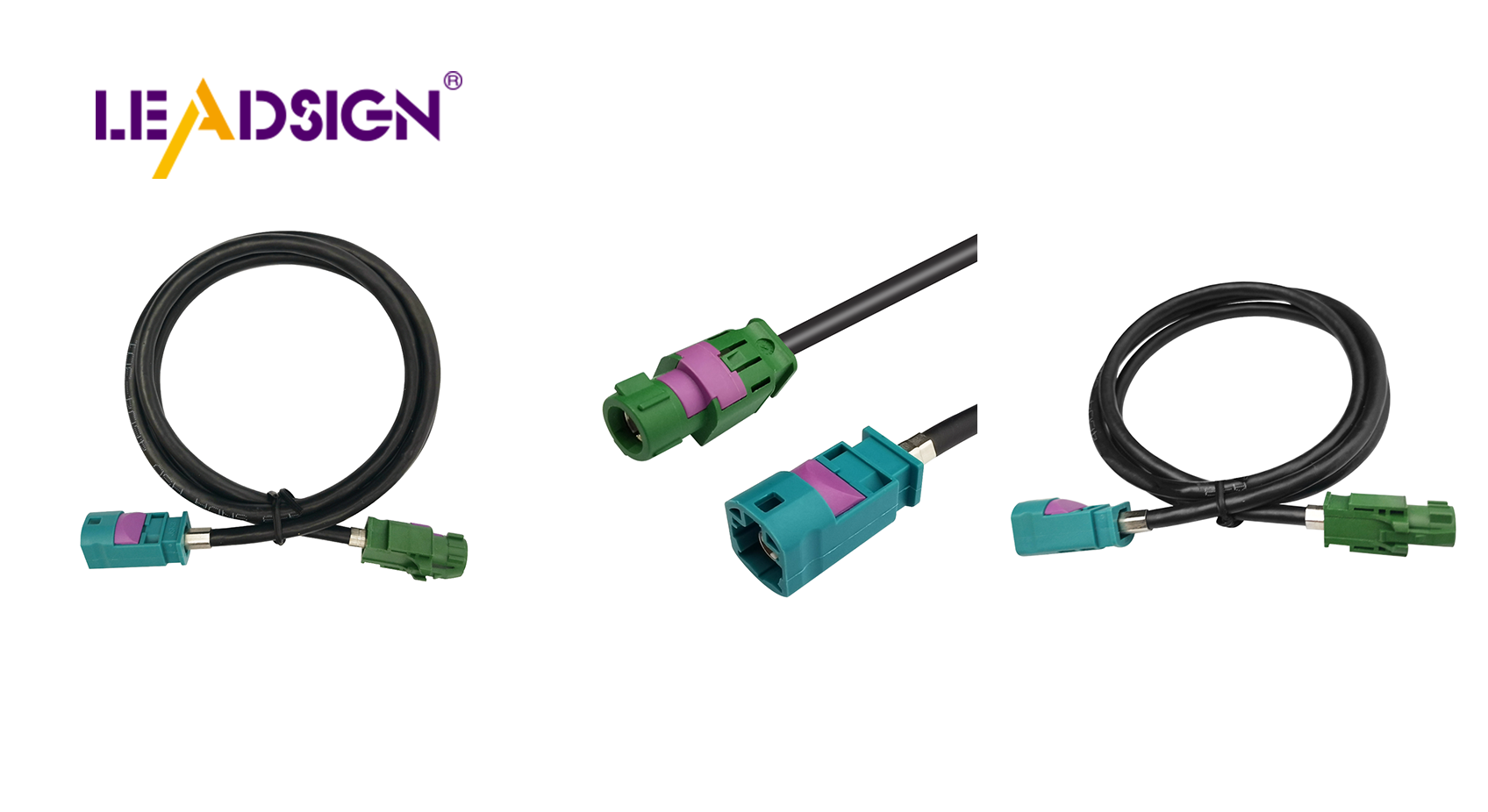

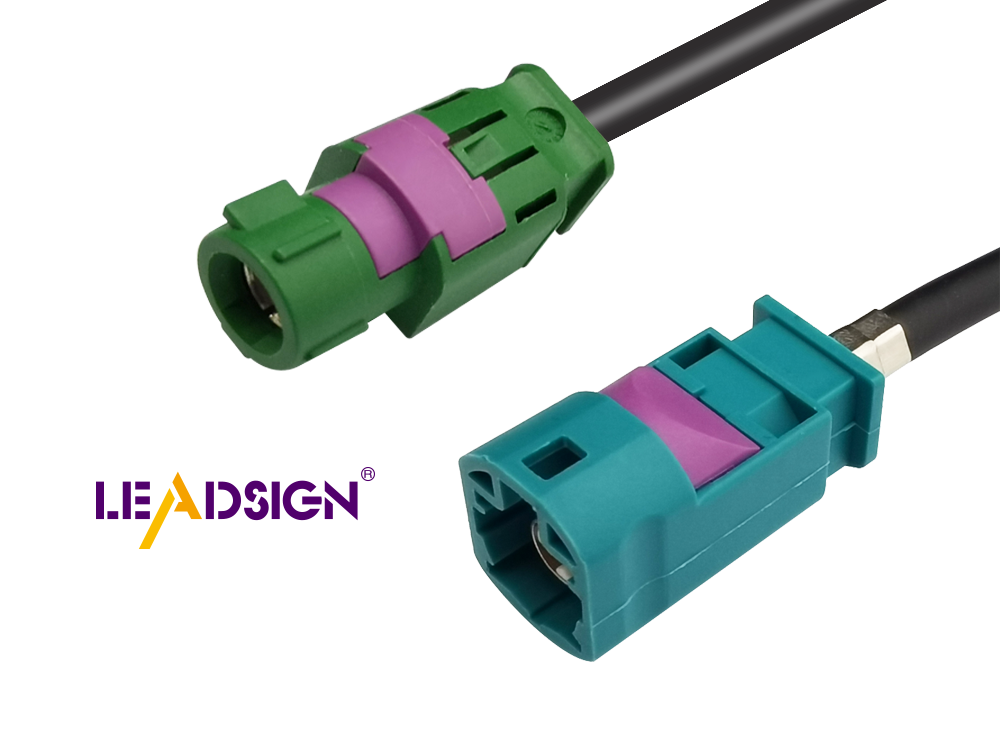

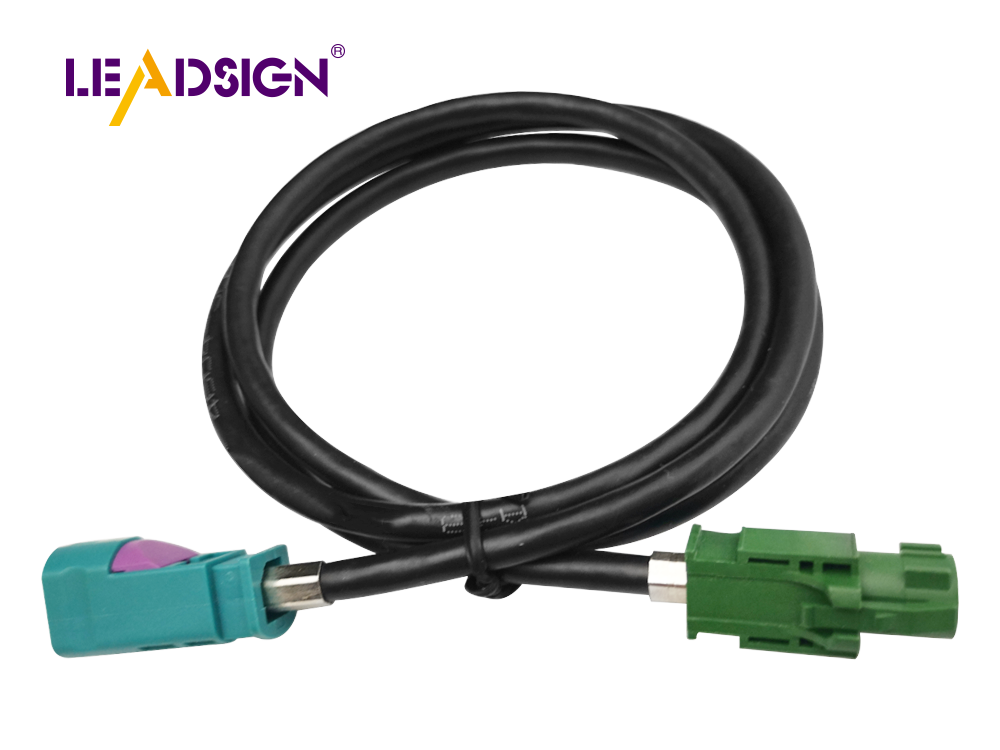

High-Speed Data Connectors

High-speed data connectors are key in new cars. Digital screens and smart systems need them. They send lots of data fast, like maps and videos.

Core Locking Area: These connectors have a strong lock part. It keeps data moving right, even when the car shakes or moves.

Applications: Used in car tech like USB, Ethernet, and LVDS systems. They work with Firewire and GVIF too, fitting many types of car wires.

Benefits: They keep data flowing correctly without mix-ups. This is important for digital parts to work well in cars.

Pigtail and Bullet Connectors

Pigtail and bullet connectors are handy for joining wires in cars. They're easy to use, so many car experts like them.

Pigtail Connectors: Extend wiring by joining many wires into one lead. Good for tight spaces needing tidy connections.

Bullet Connectors: Easy to connect or disconnect quickly. Great for lights or gadgets needing frequent changes.

Advantages: Both make car wiring safer and better. Their design stops loose connections that can cause electric problems.

Installation Techniques

Installing car wire connectors the right way keeps the car safe and working well. This part shows what tools you need and how to put these connectors in.

Tools Needed

Important tools for installation

To put in car connectors, you need some tools:

Wire Strippers: Take off wire covers without breaking them.

Crimping Tool: Holds the wire tight with the connector.

Screwdrivers: Used for turning screws on connectors.

Multimeter: Checks if electricity flows right.

Safety tips

Safety is very important when using car wire connectors. Follow these tips:

Always unplug the car battery before starting to avoid shocks.

Wear gloves to protect from cuts or burns.

Keep your work area dry to stop electric dangers.

Use tools with rubber handles to lower shock risk.

Step-by-Step Guide

Getting wires ready

Find the Wires: Know which wires to connect. Check the car's wiring map for help.

Remove Insulation: Strip about half an inch of cover off wires using strippers. This shows metal for connecting.

Check Wires: Look for damage or rust. Change bad wires for a strong connection.

Joining the wires

Pick a Connector: Choose the right type of car wire connector needed.

Put Wire In: Place bare wire into connector's crimp spot.

Crimp Connector: Use tool to hold wire firmly in place inside connector.

Secure Connector Lock: Lock it so wires don't shake loose.

Testing connection

Plug Battery Back In: After all are connected, reconnect battery of vehicle.

Test with Multimeter: Ensure circuit is complete by checking continuity with multimeter.

Check Everything Works: Turn on electric parts of car to see if they work fine.

By doing these steps, you make sure that car wire connectors are put in right, keeping cars safe and running well.

Common Issues and Maintenance

Troubleshooting Problems

Identifying common issues

Car wire connectors can have problems. Loose wires cause power failures. Rusty connectors stop electricity flow. Broken covers show wires, leading to shorts. Wrong fitting during setup stops proper contact.

Solutions and fixes

To fix these problems, do these things:

Tighten Loose Connections: Use a tool to hold loose wires tight.

Clean Corrosion: Use cleaner or brush to remove rust from connectors.

Repair Insulation: Cover bare wires with tape or change bad parts.

Correct Misalignment: Move connectors until they fit well.

Maintenance Tips

Regular inspection

Check often to keep wire connectors good. Look for wear or damage signs. Check for color changes showing heat issues. Look at covers for cracks. Make sure all connections are tight.

Ensuring longevity

To make wire connectors last longer, do this:

Apply Protective Coatings: Use grease to keep moisture away from connectors.

Avoid Overloading Circuits: Don't let electric load be too much for the connector.

Store Properly: Keep extra connectors dry and cool.

Schedule Routine Checks: Set times to check and fix connectors early.

By following these tips, car wire connectors will work well and safely in the vehicle.

Knowing about car wire connectors is important for keeping cars safe and working well. These connectors help the car's electric system run smoothly. Picking the right connector makes the car work better and last longer.

Main Ideas:

Wire connectors hold wires tight, stopping electric problems.

Different materials and styles fit different car needs.

New designs make cars safer and work better.

Why It Matters:

Choosing the right connector helps the car perform best.

Installing and caring for them keeps them working longer.

By doing things right, people can keep their cars safe and running well.

See Also

A Comprehensive Ford Fakra Connector Guide

Essential HSD Connector Insights for Automotive Sector

Significance of FAKRA Connectors in Auto Implementations