A Guide to Types of Wire Connectors in Automotive Applications

Wire connectors of the automotive type are crucial in car systems. They ensure the safe flow of electricity, which is essential for cars to function efficiently. High-quality automotive wire connectors reduce the likelihood of issues, enhancing reliability. Given the harsh conditions cars endure, these connectors must be robust and comply with standards like QC/T417.1 to ensure longevity. Selecting the appropriate wire connectors for automotive applications is vital to maintain system performance. Reliable connectors prevent electrical problems, ensuring cars operate safely and smoothly.

Basics of Wire Connectors

Definition and Function

What are wire connectors?

Wire connectors are key parts in electrical systems. They link wires together, allowing electricity to flow. In cars, there are different types like wire nuts, Wago connectors, and crimp connectors. Each type has a special job, making sure connections are safe and strong. For example, wire nuts are used at home, but crimp connectors are common in cars because they last longer.

How do they function in automotive systems?

In car systems, wire connectors are very important. They help send power and signals everywhere in the car. This includes lights and the engine control unit. Good connections stop problems like loose wires or open circuits that can cause issues. Big vehicles need strong wiring harnesses for tough conditions. These must handle shaking, temperature changes, and wetness while staying strong.

Importance in Automotive Applications

Ensuring electrical connectivity

Wire connectors keep electricity flowing in cars. They make sure power moves smoothly through circuits. Without them, car parts wouldn't work right. Different connectors like ethernet connectors and DTL connectors have specific uses. Ethernet might be for infotainment; DTL could be for engine systems.

Enhancing safety and reliability

Safety is crucial in cars. Wire connectors make things safer by keeping connections secure to avoid failures. A good connection keeps everything working well, lowering accident risks from electrical problems. Modern ones often have smart designs to stop disconnections and block out moisture or dust, which helps keep car systems safe and reliable.

Historical Changes in Wire Connectors

First Designs

Early shapes and materials

Wire connectors have changed a lot over time. At first, they were simple and made from copper and brass. These early ones joined wires tightly but were big and not fancy like today’s. Even though basic, they started the path for new ideas.

Changes in car industry

Cars got more complex, so wire connectors had to improve too. Early car connectors were like home wiring ones. But as cars improved, better connectors were needed. Standards like QC/T417.1 helped make strong connectors for cars. These rules made sure they could handle car shakes and heat changes.

New Ideas Today

Better materials and tech

Today’s wire connectors use better stuff and technology. Makers use plastics and metals that are light yet strong. They resist things like water and heat well now. Tech improvements mean better electricity flow and strength too. Some have solid solder points for less wear, lasting longer.

Effect on car design

New wire connectors change how cars are built now. Cars need good connections for their electric systems to work right. Modern ones meet tough needs of the car world, like Rosenberger FAKRA* types do this well with GPS or safety sensors added in cars today.

Types of Wire Connectors in Cars

Crimp Connectors

Types and uses

Crimp connectors are popular for cars. They squeeze the connector onto the wire to hold it tight. This makes a strong link that handles shakes and tough conditions. There are different kinds like butt connectors, ring terminals, and spade terminals. Each has a job, like joining wires or linking to a block.

Advantages and disadvantages

Crimp connectors have good points. They make strong links needed in cars. No soldering is needed, so they’re fast to put on. But you need special tools to do it right. If done wrong, the link can be weak and cause problems. So, follow rules and use the right tools.

Solder Connectors

Types and uses

Solder connectors join wires by melting metal around them for a lasting bond. They're used where strong links matter most. You can find them as solder sleeves or solder cups. They work best where there’s little shaking, keeping connections long-lasting.

Advantages and disadvantages

Solder connectors make very strong links that don’t loosen easily. They're great for important car systems but need skill to use heat without harm. Once done, they’re hard to undo, making fixes tricky.

Push-In Connectors

Types and uses

Push-in connectors let you connect wires easily without tools. Just push the wire in; a spring holds it tight. They come in types for one or more wires at once. These are handy when quick connections are needed.

Advantages and disadvantages

Push-in connectors save time during setup with their easy design. They keep wires snug but might not last in shaky places as springs weaken over time. Also, they may not fit big wires, limiting their use.

Special Connectors

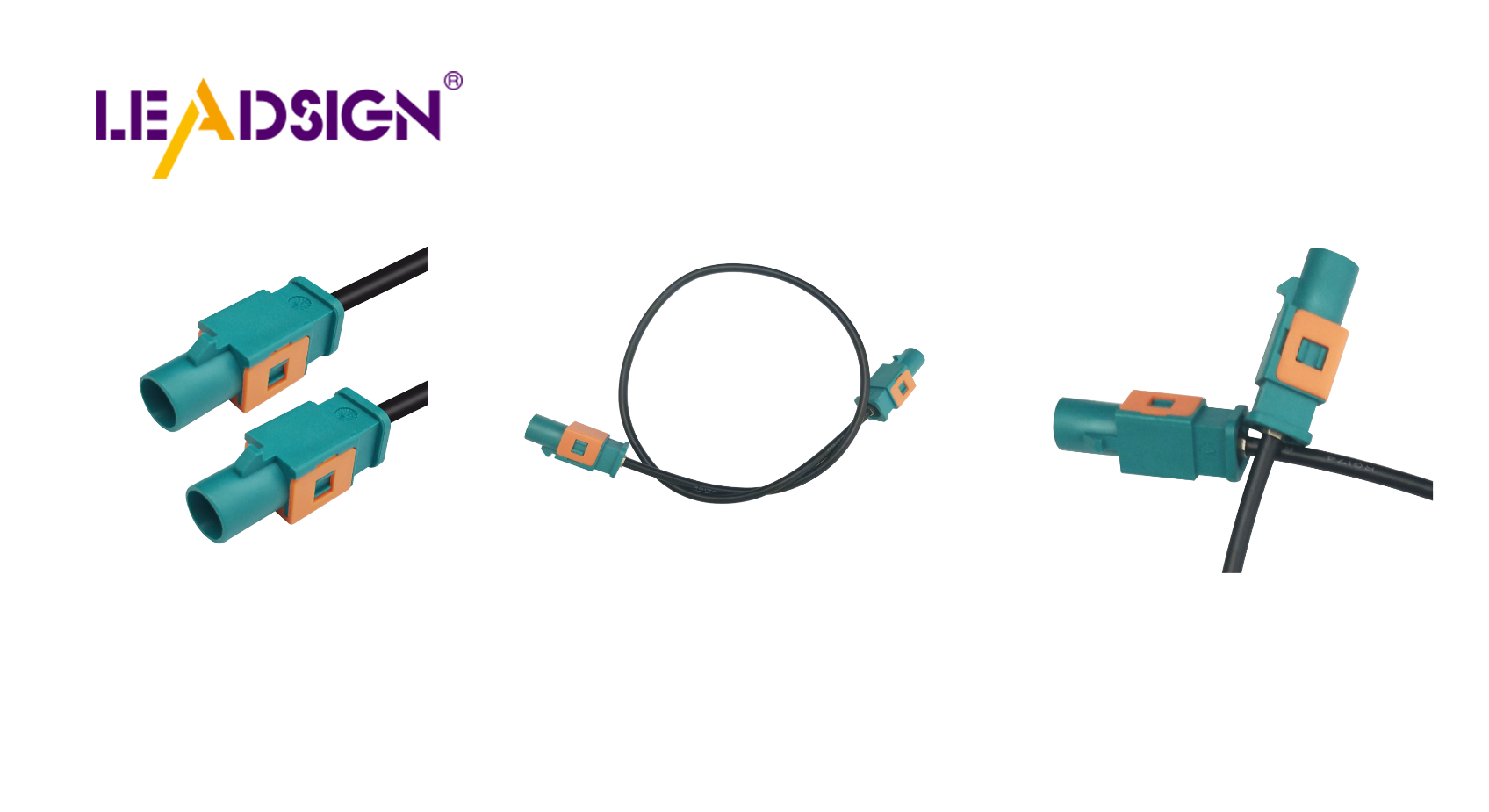

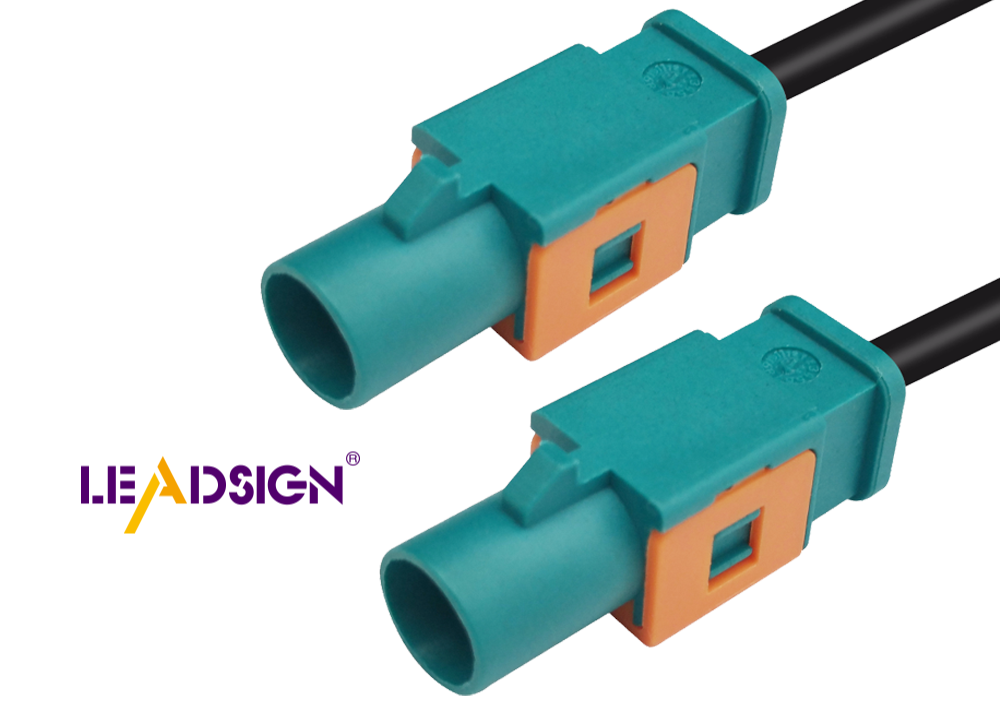

FAKRA Connectors

FAKRA connectors are special wire connectors for cars. They handle tough car needs. These connectors make sure high-frequency signals work well, which is important in new cars. FAKRA connectors have a smart system to stop wrong use, making them safe and reliable. They have two locks to keep connections strong even in hard situations.

FAKRA connectors come in different types like cable, PCB, and panel connectors. Each type has its own job, giving options for car use. They work with frequencies from DC to 6 GHz and data rates up to 8 Gbps. This makes them good for fast data systems in cars.

Uses in Car Systems Like GPS and Radio

FAKRA connectors are used a lot in car systems like GPS and radio. They are the main link for high-frequency jobs, keeping connections smooth. In GPS, they help with accurate directions by keeping a steady link between the antenna and navigation system. This is key for real-time location info.

In radios, FAKRA connectors give clear sound by linking the antenna to the audio system. This lets people enjoy radio without breaks even with weak signals around. Also, they support other uses like infotainment and Bluetooth RF applications because of their strong build.

FAKRA connectors are also crucial for car safety systems. They connect sensors that check and react to things around the car, keeping it safe. These connectors can handle extreme heat and shaking while staying strong. By giving secure links, FAKRA connectors help keep car systems working safely.

Installation Techniques

Tools Needed

Important tools for installation

To install wire connectors in cars, you need certain tools. These tools help make sure connections are safe and work well. The main tools are:

Wire Strippers: These take off the plastic cover from wires without hurting the metal inside.

Crimping Tools: Used with crimp connectors, they press the connector onto the wire tightly.

Soldering Iron: Needed for solder connectors, it melts solder to join wires strongly.

Heat Gun: Often used with heat shrink connectors to seal out water.

Multimeter: This checks if electricity flows right and measures voltage.

Safety tips

Being safe is very important when installing wire connectors. Follow these safety tips:

Wear Protective Gear: Use gloves and goggles to stay safe from shocks and flying bits.

Disconnect Power: Always unplug the car battery before starting to avoid shocks.

Work in a Fresh Air Place: Soldering makes smoke, so have good air flow.

Follow Maker Instructions: Each connector type has its own steps. Following them keeps connections strong.

Step-by-Step Guide

Getting wires ready

Getting wires ready is key for success. Do these steps:

Cut the Wire: Trim the wire to the needed length with cutters.

Strip the Insulation: Take off about 1/4 inch of cover from each wire end using strippers.

Twist the Strands: For stranded wires, twist them together to stop fraying.

Connecting and securing

After preparing wires, connect and secure them like this:

Pick the Connector: Choose crimp, solder, or push-in based on what you need.

Attach the Connector:

For crimp connectors, put stripped wire in and use a tool to crimp it tight.

For solder connectors, place wire in and melt solder with an iron until it bonds well.

For push-in connectors, just push wire in until it clicks into place.

Secure Connection: Use a heat gun to shrink any tubing over connection for extra protection against wetness and shaking.

Test Connection: Use a multimeter to check if connection is secure and working right.

By following these steps with correct tools, installers can make sure car wire connectors are put on safely and correctly. Good installation process boosts how well car's electrical system works, making it safer too.

Common Issues and Maintenance

Troubleshooting Problems

Finding common problems

Car wire connectors can have issues that affect them. Loose connections happen if not installed right or with time. Rust is another problem, especially where it's wet or salty. This makes electricity flow poorly and can break the connection. Also, too much heat can harm connectors from high current or bad insulation.

Fixing problems

To fix these, find what's wrong first. For loose wires, make sure they are crimped or soldered well. Use tools like crimpers or solder irons for a tight fit. To stop rust, check connectors often and clean them with good cleaners. Use grease to keep water out. If too hot, check the power load matches the connector's limits. Replace bad ones with strong brands like Neutrik for better use.

Maintenance Tips

Regular checks and care

Regular care helps connectors last longer in cars. Check often for wear, rust, or damage signs. Look for color changes or melting as it shows overheating. Make sure all wires stay tight and safe. Early fixes stop bigger problems later.

Making connectors last longer

To keep wire connectors working long, store them well in dry places away from heat and cold. When putting them in cars, follow maker rules for best use. Good solder points and crimping help make strong links that last long. Doing this keeps car systems working safely.

Q&A Section

Common Questions

Reader Questions on Wire Connectors

What problems do car wire connectors face?

Car wire connectors can have loose connections and open circuits. These happen because contact parts in wiring harnesses move. Weather, like rain and heat, can also hurt these connectors. Installing them right and checking often helps fix these issues.

How to keep wire connectors working well in tough places?

To keep them working, use connectors that are sealed well. This stops loose connections from happening a lot. Storing them right and having strong solder points also helps them last longer in hard conditions.

Which wire connectors are best for high-frequency uses in cars?

For things like GPS and radio, FAKRA connectors are best. They give safe connections even when it's tough for cars. Their design stops wrong use and keeps everything secure.

Expert Tips on Care and Choice

How to make wire connectors last longer?

Check them often for wear or rust signs. Make sure all wires stay tight and safe. Clean with the right stuff and use grease to stop water getting in.

How to pick the right connector for a car job?

Think about what you need it for first. Crimp ones are good where there's shaking; solder ones fit stable spots better. Look at what they're made of, how hot they can get, and their frequency limits.

By answering these questions, readers learn how to care for and choose the best wire connectors for their cars, making systems safer.

Wire connectors are important in cars. They help electricity flow safely, which is needed for cars to work well. Different kinds, like crimp and solder connectors, have special uses. Knowing about them helps people pick the right one, making cars safer and more reliable. Using this knowledge means car systems can work better and last longer.

See Also

Exploring Ford Fakra Connectors in Depth

Essential HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses