A Complete Guide to Types of Wire Connectors Automotive Enthusiasts Should Know

Wire connectors are crucial components in automotive systems. They play a vital role in ensuring proper electrical connections within vehicles. Understanding the various auto wire connector types is essential for maintaining the functionality and safety of your car. This informative guide educates automotive enthusiasts on the different types of auto wire connectors available. Familiarizing yourself with these types empowers you to make informed decisions when repairing your vehicle. Enhancing your knowledge of auto wire connector types enables you to enhance the performance of your car's electrical components and avoid potential issues.

Understanding Wire Connectors

What are Wire Connectors?

Definition and basic function

Wire connectors join wires in electrical systems. They keep connections stable and secure. This helps electricity flow, which is important for cars to work right. Without them, car circuits would not work, causing problems.

Importance in automotive systems

In cars, wire connectors are very important. They help power reach lights, sensors, and gadgets. Using the right ones stops failures and makes your car reliable. Some resist corrosion to keep working well over time.

Common Materials Used

Copper

Copper is often used for wire connectors because it conducts electricity well. It reduces energy loss and is found in many car parts. Copper also resists rust, making it last long.

Aluminum

Aluminum is another option for wire connectors. It's light and cheap but can rust more than copper. To fix this, makers use aluminum with copper or coat it with tin to stop rusting.

Plastic and Insulation Materials

Plastic protects wire connectors from water and dirt. Many have plastic covers to stop short circuits and stay safe. Insulation keeps connections strong by stopping contact with other metals.

Scientific Research Findings: Making wire connectors involves steps like getting materials, preparing them, putting them together, checking quality, and packing them. These steps make sure they work well in cars.

Understanding Auto Wire Connector Types

Butt Connectors

Features and uses

Butt connectors join two wires end-to-end. They make sure signals pass well. You see them in car repairs for wire extensions or swaps. Their design is simple, good for beginners. Butt connectors join two wires.

Installation process

To install, use a wire stripper and crimper. Strip the wire ends first. Put them in the connector and crimp tightly. This stops disconnection.

Ring and Spade Terminals

Differences between ring and spade

Ring terminals have round ends to bolt securely. Spade terminals have forked ends, easy to connect or disconnect. Each type has different uses. Ring terminals have round ends.

Applications in automotive systems

In cars, ring terminals are great for permanent connections like grounding wires. Spade terminals are good when you need frequent disconnections, like in fuse boxes.

Quick Disconnects

Advantages and disadvantages

Quick disconnects are handy. You can connect or disconnect without tools easily. But they might not be as secure as other types, so choose wisely.

Common uses in vehicles

You find quick disconnects where maintenance happens often, like battery spots. They help with fast changes during repairs.

Product Insight: Companies like Molex and TE Connectivity offer many connectors, including quick disconnects, for different car needs. Their products keep your car's electrical systems reliable.

Bullet Connectors

Design and Function

Bullet connectors are easy to use. They have a male and female end that fit tightly. This makes connecting and disconnecting wires simple. The bullet shape keeps them from coming apart by accident. You can find different sizes for various wire thicknesses.

Product Insight: Companies like Molex LLC and TE Connectivity make many bullet connectors. They offer reliable options for cars, keeping systems safe.

Common Uses

In cars, bullet connectors are used where parts change often. You'll see them in lights, connecting headlights or taillights to wires. They're also in audio systems for speakers. Their flexibility makes them popular with car fans who like their ease.

Did You Know?: JST Mfg. Co., Ltd. and Hirose Electric Co. Ltd. make strong connectors, including bullets, for tough car conditions.

Knowing about bullet connectors helps you choose the right ones for your car's electrical needs, improving performance and safety.

Picking the Best Connector

Choosing the right connector is important. It helps your car work well and stay safe. Here’s how to choose wisely.

Things to Think About

Wire Size Match

Make sure the connector fits the wire size. This keeps connections strong and electricity flowing well. Wrong sizes can cause bad connections and problems. Always check details to get the right fit.

Environment Factors

Think about where you’ll use the connector. Water, heat, or chemicals can change how it works. Pick connectors that handle these conditions. Copper ones resist rust, while aluminum is light and cheap. Bimetallic connectors are tough for rough places.

Brand Picks

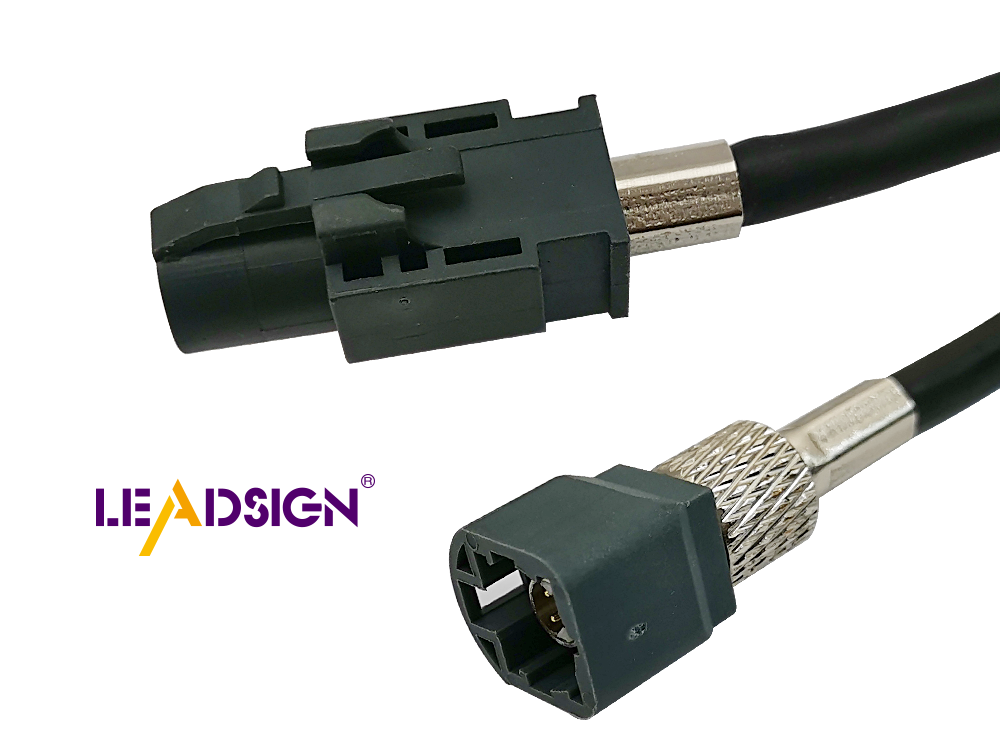

LEADSIGN

LEADSIGN makes good connectors like HSD Connector. They’re great for car electronics and send data fast. They lock well for safety and work with USB and Ethernet.

Delphi

Delphi is a reliable brand too. They have many strong connectors for different needs in cars.

Picking the right connector means knowing what you need and thinking about wire size and environment. Choosing brands like LEADSIGN and Delphi gives you quality for your car’s electric parts.

Installation and Maintenance

Installing and caring for wire connectors keeps your car's electrical system working well. Here's how to do it.

Installation Tips

Tools Needed

Gather these tools:

Wire stripper

Heat gun (for heat shrink)

Screwdriver (if needed)

Having them ready makes work easier.

Step-by-Step Guide

Strip the Wire: Use a wire stripper to take off about half an inch of insulation. This shows the metal for a good link.

Insert into Connector: Put the stripped ends into the connector snugly. This stops loose connections.

Crimp Securely: Use a crimping tool to press tightly around the wire. This is key for a strong connection.

Apply Heat (if needed): For heat shrink, use a heat gun to shrink tubing around it. This protects from water and dirt.

Check the Connection: Gently pull wires to make sure they are tight. A firm hold stops future problems.

Maintenance Practices

Regular care keeps connectors in great shape, ensuring they work well.

Regular Inspection

Check connectors often for wear or damage. Finding issues early helps fix them before they get worse.

Cleaning and Replacement

Use a soft brush to clean dirt away. If you see rust, replace it quickly. Using good materials like copper helps stop rust, making them last longer.

Expert Insight: Knowing how wire connectors are made helps find ways to improve, saving time and money. Regular care is important in this process.

By following these tips, your car's electrical system stays reliable and efficient.

Finding and Buying

Getting the right place to buy wire connectors is key. It ensures you get good products for your car. Here’s where to look and what to think about when buying.

Where to Buy

Online Shops

Shopping online is easy and has many choices of wire connectors. Websites like Amazon, eBay, and special car parts stores have lots of options. You can check prices, read reviews, and see product details. This helps you choose wisely. Online sites often give discounts, making it cheaper to find good deals.

Local Car Stores

Going to local car stores lets you see items up close. You can ask staff for help and advice. This personal touch is helpful if you're unsure about which connector you need. Local stores might also install them or offer extra help, making buying easier.

Cost Factors

Budget Options

When buying wire connectors, think about your budget. Many cheap options are good quality without costing too much. Brands like Delphi have reliable connectors at fair prices. Look for sales or bulk deals to save money while getting what you need.

High-Quality Choices

For top-quality connectors, brands like LEADSIGN have advanced features. These often use better materials and last longer. Spending more on these can be worth it for important uses where reliability matters most. They may cost more first but last longer and work better.

Interview Insight: Someone with wire harness experience said using quality connectors is vital. They noted that good ones stop future problems and keep systems stable.

By thinking about where to buy and costs, you make smart buys for wire connectors. Whether choosing budget or premium types, ensuring they fit your needs keeps your car's electrical system strong.

FAQs

Common Questions

How to pick the right connector?

To choose a connector, think about a few things. First, look at the material. Copper is common because it carries electricity well. Brass is strong, and plastic keeps it safe from short circuits. Next, check the wire size. The connector should fit the wire snugly for good flow.

Also, consider the environment where you'll use it. If it's wet or hot, pick connectors that don't rust easily like bimetallic ones. They work well in tough spots. Lastly, know your application needs. Different connectors do different jobs, so know what your car's system needs.

What shows a bad connector?

Finding a bad connector early can stop big problems in your car's electrical system. Watch for these signs:

Flickering Lights: If lights blink or gadgets act weirdly, the connector might be loose or rusty.

Visible Cracks: Check for breaks or rust on the connector as they can stop electricity flow.

Feels Hot: A hot connector may mean a weak link causing heat and resistance.

Burnt Smell: A burnt smell near it means overheating or shorting out; fix it fast.

Color Changes: Darkening colors show overheating or rusting.

Check connectors often to spot these issues early on. Clean them and swap damaged ones to keep your car's electric parts working well.

Picking the right wire connectors is important for your car's safety. Knowing different types helps you make smart choices. Learn about these connectors to improve your car's electrical parts. Good connectors make sure connections are strong, lowering the chance of problems. Spend time learning to keep your car working well.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive: A Beginner's Guide

Significance of Fakra Connectors in Today's Automobiles

Crucial Role of FAKRA Connectors in Auto Industry

In-Depth Look at Fakra Connectors: Benefits, Uses, and Setup Advice