Guide to Identifying Vehicle Connectors

Knowing vehicle connectors helps keep your car safe and working. Bad connectors can cause electrical problems and risks to your car. Checking and replacing them often stops these problems. Fixing connector issues makes driving safer and more reliable. This guide makes it easy to solve common connector problems.

Key Takeaways

Regularly check and maintain vehicle connectors to prevent electrical issues and ensure your car runs safely and efficiently.

Use a multimeter to test connectors for voltage and resistance, helping you identify any problems before they escalate.

When replacing connectors, always disconnect the battery first and ensure the new connector matches the old one in shape and pin configuration.

Understanding Vehicle Connectors

What Are Vehicle Connectors?

Vehicle connectors are important parts of your car's electrical system. They join circuits together so electricity can flow and systems work. These connectors help your car run safely and efficiently. Without them, systems like the engine, lights, and music wouldn't work.

Think of connectors as bridges linking electrical parts. They let signals and power move smoothly, keeping your car working right. From starting the engine to playing music, connectors are key to everything running well.

Key Terminology and Components

To understand connectors, you need to know their main parts. Here are some important ones:

Housing: The outside cover that protects the inside parts.

Pins or Terminals: Metal pieces that send electrical signals.

Locking Mechanism: A part that keeps the connection secure.

Seals: Rubber or plastic pieces that block dirt and water.

You might also hear about "male" and "female" connectors. Male ones have pins, and female ones have sockets for the pins.

Categories of Vehicle Connectors (Electrical, Diagnostic, Sensor)

There are three main types of connectors in cars:

Electrical Connectors: These send power and signals for things like lights and batteries.

Diagnostic Connectors: Found in the car's OBD system, they help mechanics find problems.

Sensor Connectors: These link sensors to control units for brakes and airbags.

Each type has a special job, but all are important for safety and performance.

Common Types of Vehicle Connectors

Electrical Connectors

Electrical connectors are key to your car's functions. They move power and signals to keep things running. You can find them in lights, batteries, and other parts.

Here are some common electrical connectors:

Bullet Connectors: Great for quick and easy wire disconnections.

Scotch Locks: Join wires without needing to strip or solder them.

Crimp Connectors: Make strong and dependable wire connections.

Heat Shrink Connectors: Protect wires from weather and outdoor damage.

Weather Pack Connectors: Handle tough conditions like rain and dirt.

Deutsch Connectors: Tough and used in heavy-duty equipment.

Molex Connectors: Flexible and simple for modern car designs.

USB Connectors: Used to connect phones and other devices.

Diagnostic Connectors

Diagnostic connectors help find car problems. They link the OBD system to a scanner. Mechanics use them to check error codes and fix issues. These connectors are usually under the dashboard.

Sensor Connectors

Sensor connectors join sensors to control units. They check systems like brakes, airbags, and engines. For example, brake sensor connectors help ABS work properly. Without them, safety features wouldn’t work right.

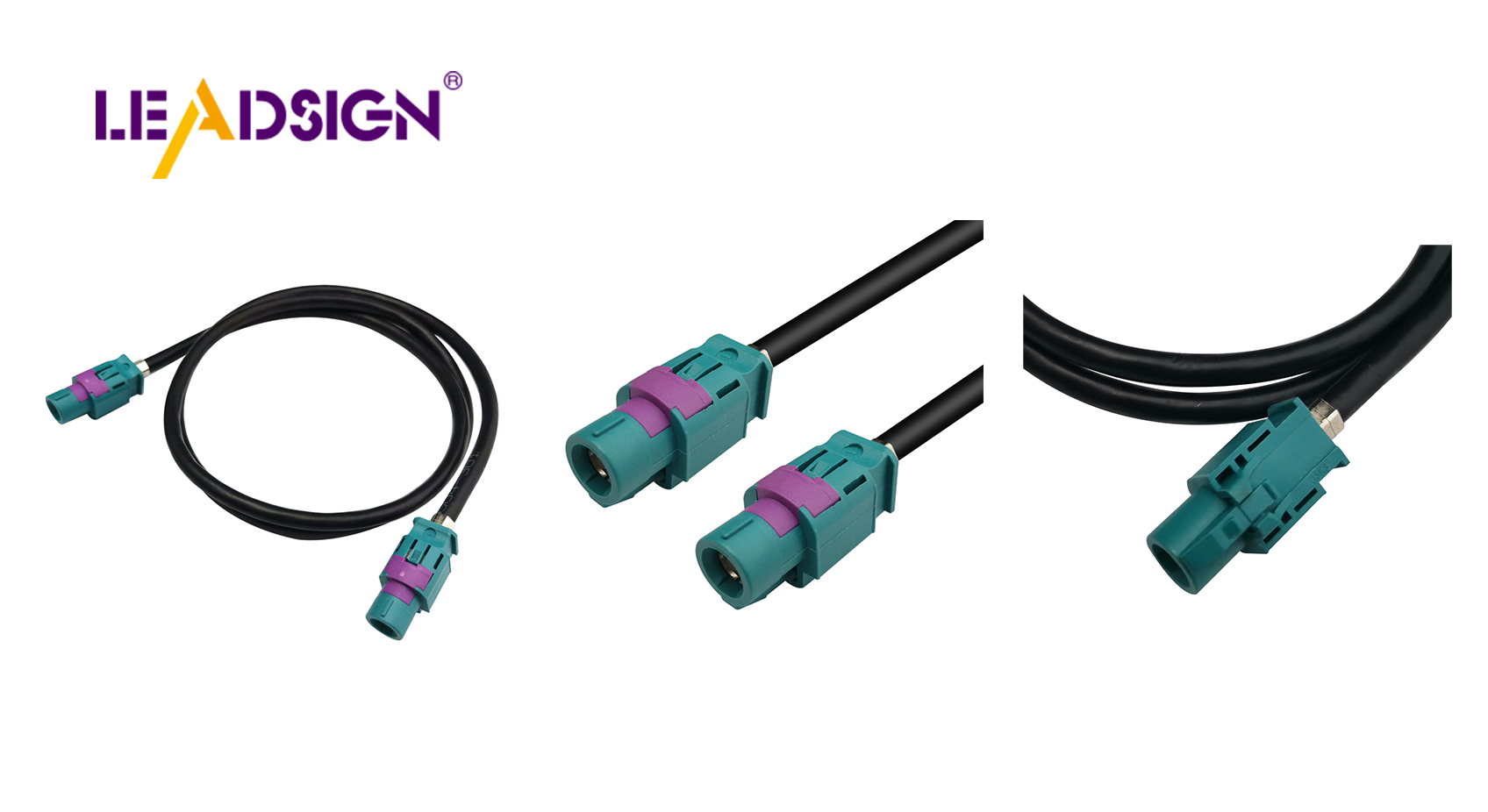

High-Speed Data (HSD) Connectors

High-Speed Data (HSD) connectors are vital for modern cars. They send fast data for cameras, USBs, and screens.

Feature | Description |

|---|---|

Performance | |

Shielding | Fully protected for different wire types |

Compatibility | Works with LVDS, Ethernet, and USB |

Application Range | Fits sealed and unsealed uses |

PCB Header Portfolio | Offers many PCB header options |

Manufacturing | Made with high-tech processes worldwide |

Compliance | Meets standards like IDB 1394, USCAR 2, and RoHS |

These connectors improve data flow and system compatibility. They are crucial for today’s advanced vehicles.

How to Identify Electrical Connectors

Easy Steps to Identify Connectors

Finding electrical connectors in your car is simple. Follow these steps:

Prepare First: Get tools like a multimeter and guidebook. Disconnect the battery for safety.

Check the Connector: Notice its shape, color, and pin layout. These details show its type.

Test It: Use a multimeter to check voltage or resistance. This shows if it works.

Match It: Compare it with a guide or online pictures. This helps find the right replacement.

Tip: Be gentle to avoid breaking pins or covers.

Tools to Help You Identify

Use these tools to easily find the right connector:

Multimeter: Measures voltage and resistance to check if it works.

Guidebook: Pictures and details help you know connector types.

Look Closely: Check size, shape, and color. Count pins to narrow choices.

Note: A flashlight helps you see better in tight spots.

Key Features to Notice (Shape, Color, Pins)

When finding connectors, focus on these main things:

Shape: They can be square, round, flat, or rectangular.

Color: Colors often show what type the connector is.

Pins: Count and check how pins are arranged. This ensures it fits.

Reminder: Some connectors only fit one way to avoid mistakes.

By using these steps and tools, you can easily find and identify electrical connectors in your car.

Replacing Vehicle Connectors

Tools Needed for Replacement

You need the right tools to replace connectors easily. Here’s what to have:

Multimeter: Checks if electricity flows correctly.

Wire Cutters: Cuts wires to the needed size.

Crimping Tools: Helps attach wires to the connector.

Soldering Gear: Makes wire connections stronger.

Magnifying Glass: Helps see small parts clearly.

Contact Cleaner: Cleans dirt and rust from connectors.

Having these tools ready makes the job faster and easier.

Step-by-Step Guide to Replacing Connectors

Follow these steps to replace connectors safely:

Gather Tools: Get tools like a multimeter, wire cutters, and crimpers.

Disconnect Battery: Remove the battery’s negative terminal to stay safe.

Take Out Old Connector: Press or unscrew to remove the broken connector.

Check New Connector: Compare it with the old one to ensure it matches.

Attach Wires: Use crimpers to secure wires, then solder for strength.

Reconnect Battery: Put the battery back and test the new connector.

Tip: Use a multimeter to confirm the connection works.

Safety Tips During Replacement

Stay safe while working on connectors by following these tips:

Disconnect the battery to avoid shocks or accidents.

Wear gloves and safety glasses to protect yourself.

Work in a clean, bright area to avoid mistakes.

Stop if you see sparks, smoke, or smell burning.

By being careful, you can replace connectors safely and easily.

Tips and Best Practices

Maintenance Tips for Longevity

Taking care of connectors helps them last longer. Follow these tips:

Seal them to keep out dirt and water.

Use tape or tubing to cover exposed connectors.

Check wires to avoid wrong connections or broken lights.

After tough weather, check for water or loose wires.

Secure connectors to stop damage from bumps or debris.

These steps save money and keep your car working well.

Troubleshooting Common Connector Issues

Connectors can have problems over time. Here’s how to fix them:

Rust, cracks, or melted parts can stop them from working. Replace bad connectors quickly.

Heat, cold, or water can weaken them. Seal them to protect.

Vibrations can loosen or damage connectors. Tighten them to fix this.

Flickering lights or dashboard issues may mean connector trouble. Check and repair them.

Small damage can be fixed, but big problems need new connectors.

Regular checks and quick fixes keep connectors working.

When to Seek Professional Help

Sometimes, you need an expert for connector problems. Look for these signs:

Lights flicker or sensors stop working. This shows weak connections.

Cracks, rust, or bent pins mean it’s time to replace them.

Loose connectors that don’t fit right need expert help.

Bad smells or heat near connectors could mean serious issues.

If you see these signs, get help fast. A professional can fix the problem and keep your car safe.

This guide helps you understand how to manage connectors well. Check them often for rust or broken pieces. Use a multimeter to see if they work. Always disconnect the battery before replacing connectors. After replacing, test the system to make sure it works.

Taking care of connectors keeps your car working better. Clean them and use grease to stop rust. Seal open ones to keep out dirt. Check wires after bad weather to avoid problems. By doing these steps, your car stays safe and reliable.

Use these tips now to keep your car running great.

FAQ

What are common problems with vehicle connectors?

Loose wires, rust, and broken pins happen often. Checking and cleaning them regularly can stop these problems.

How do you pick the right connector for your car?

Make sure the connector's shape and pins match your car's system. Use the car manual or ask an expert for help.

Should you fix or replace a broken connector?

You can fix small issues like loose pins. Replace connectors if they are rusty, cracked, or melted to keep your car safe.

See Also

Understanding Ford Fakra Connectors For Your Needs

An In-Depth Look At HSD Connectors Explained

Detailed Insights Into Fakra Male Connectors