Guide to Choosing Automotive Wiring Connector Types

Selecting the appropriate wire connectors automotive type is crucial for maintaining the safety and efficiency of your vehicle's electrical system. Automotive wiring systems are intricate and require precise connections to function correctly. There are various types of connectors, each designed for a specific purpose. Using the right connector reduces electrical resistance, enhancing the longevity and performance of your car components. Moisture and corrosion can damage connectors, so it's essential to choose wisely to ensure reliability.

Understanding Wire Connectors Automotive Type

Picking the right wire connectors automotive type is key for your car's electrical safety and efficiency. Let's look at different connector types, materials, and ratings to help you choose wisely.

Types of Wire Connectors Automotive Type

Blade Connectors: Blade connectors are common in cars. They are flat and slide into a slot. These connectors are secure and easy to use.

Ring Connectors: Ring connectors are round and fit over screws or bolts. Use them for grounding or connecting wires securely in shaky places.

Butt Connectors: Butt connectors join two wires end-to-end by crimping them together. They fix or extend wires well.

Bullet Connectors: Bullet connectors have male and female parts that snap together quickly, useful for easy disconnection in cars.

Connector Materials

Metal Connectors: Metal connectors made from copper or brass conduct electricity well and handle heat but can rust if wet.

Plastic Connectors: Plastic connectors resist rust and are light, good where moisture is an issue, though they don't conduct as well as metal.

Connector Sizes and Ratings

Current Rating: This tells how much current a connector can carry safely. Pick one that matches the system to avoid fires.

Voltage Rating: This shows the highest voltage a connector can handle without breaking down under load.

"Wear on terminals raises resistance between connectors, causing signal loss in low power data ones or heat in high power ones."

Knowing about wire connectors automotive type helps you pick the best parts for your car’s wiring system by considering type, material, and ratings for reliable connections.

Important Things to Think About When Picking Connectors

When choosing wire connectors automotive type, think about key things for best performance. These include the environment, electrical needs, and how they will be used. Knowing these helps you pick the right ones for your car.

Environmental Factors

Heat Resistance

Heat resistance is important when picking wire connectors automotive type. Hot temperatures can make connectors break, which can be dangerous. Choose connectors that handle the heat from your car's system well. Scientific Research Findings: Thicker electroplating helps spread heat better in connectors. This means thicker layers can improve heat resistance, keeping them working in hot conditions.

Water and Rust Resistance

Water and rust can harm wire connectors automotive type badly. If wet, they might rust and cause problems like short circuits. To stop this, pick ones with coatings or materials that fight rust. Scientific Research Findings: Water can damage terminal surfaces and cause shorts. Using connector greases stops water problems, making connections last longer.

Electrical Needs

Conducting Electricity

Conducting electricity well is crucial for wire connectors automotive type. You need them to carry electricity efficiently to keep your car's system running smoothly. Metal ones like copper or brass conduct electricity very well, ensuring they manage loads without overheating.

Protection Layer

Protection keeps wire connectors automotive type safe from shorts and outside factors. Good protection makes sure they stay safe and work right. Look for high-quality protection materials that meet your car’s needs to avoid shorts and keep connections strong.

Physical Needs

Strength

Strength matters when picking wire connectors automotive type. They must handle your car’s tough conditions like shaking or hits without breaking down over time.

Easy to Use

Easy use is also key for wire connectors automotive type. You want ones simple to put on or take off for quick fixes or checks. User-friendly designs like snap-together types make it easy to manage wiring without trouble.

Thinking about these important things helps you choose the right wire connectors automotive type for your vehicle, keeping its electrical system safe and reliable.

Application-Specific Considerations

When picking car wire connectors, think about where they'll be used. Different parts of your car need different connectors for best safety and work.

Automotive Applications

Engine Compartment

In the engine area, it's hot and shaky. You need strong connectors that handle heat and movement. Check out standards like USCAR-2 by experts to pick the right ones. These rules help make sure connectors work well in tough engine spots.

Interior Wiring

Inside the car, connectors should be easy to use and look nice. They must be simple to put in or take out for quick fixes. Plastic ones are good here because they are light and don't rust.

Specialized Applications

High-Performance Vehicles

Fast cars need special connectors for more power. Choose ones with low resistance and strong build. Gold or silver-plated ones conduct electricity well, even when things get intense.

Electric Vehicles

Electric cars have special needs for wire connectors. They need to handle high voltage safely and fit in small spaces. The HFM system is good because it saves space, perfect for tight electric car areas.

By thinking about these details, you can pick the best wire connectors for your car's needs, keeping it safe and working well.

When picking car wire connectors, keep these points in mind. First, think about where they will be used and what power is needed. Pick connectors that fit places like the engine or inside the car. This helps them handle heat, water, and shaking. Second, focus on safety and how well they work. Choose good materials for better power flow and protection. Lastly, make sure your picks help your car last longer and work better. Knowing these things helps you choose wisely to keep your car's wires safe and working well.

See Also

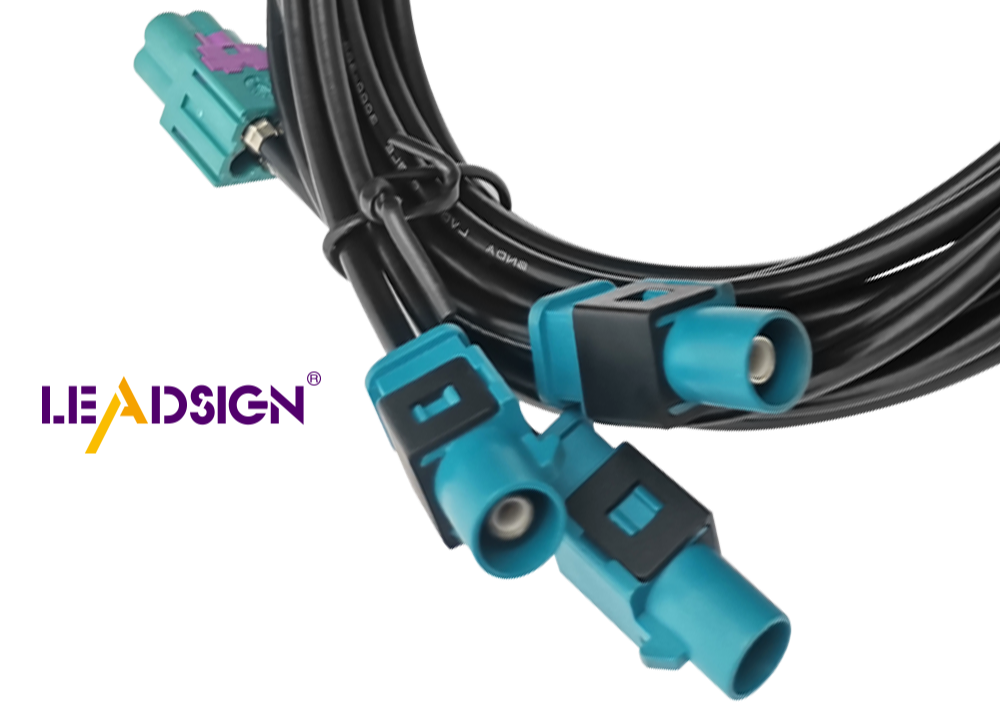

Navigating Ford Fakra Connector Essentials

Essential HSD Connector Insights for Auto Sector

Significance of Modern Vehicle Fakra Connectors