Future Trends in Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components in vehicles. They play a vital role in ensuring the proper functioning of various systems such as entertainment and safety features. The landscape of automotive electrical connectors is evolving rapidly, driven by advancements in technology and the shift towards electric vehicles. The market for automotive electrical connectors is projected to expand from USD 7.01 billion in 2024 to USD 8.76 billion by 2029, representing a growth rate of 4.53%. This growth underscores the increasing importance of these connectors in the automotive industry. Looking ahead, future trends indicate that automotive electrical connectors will continue to evolve to address new requirements and challenges in the automotive sector.

Current State of Automotive Electrical Connectors Types

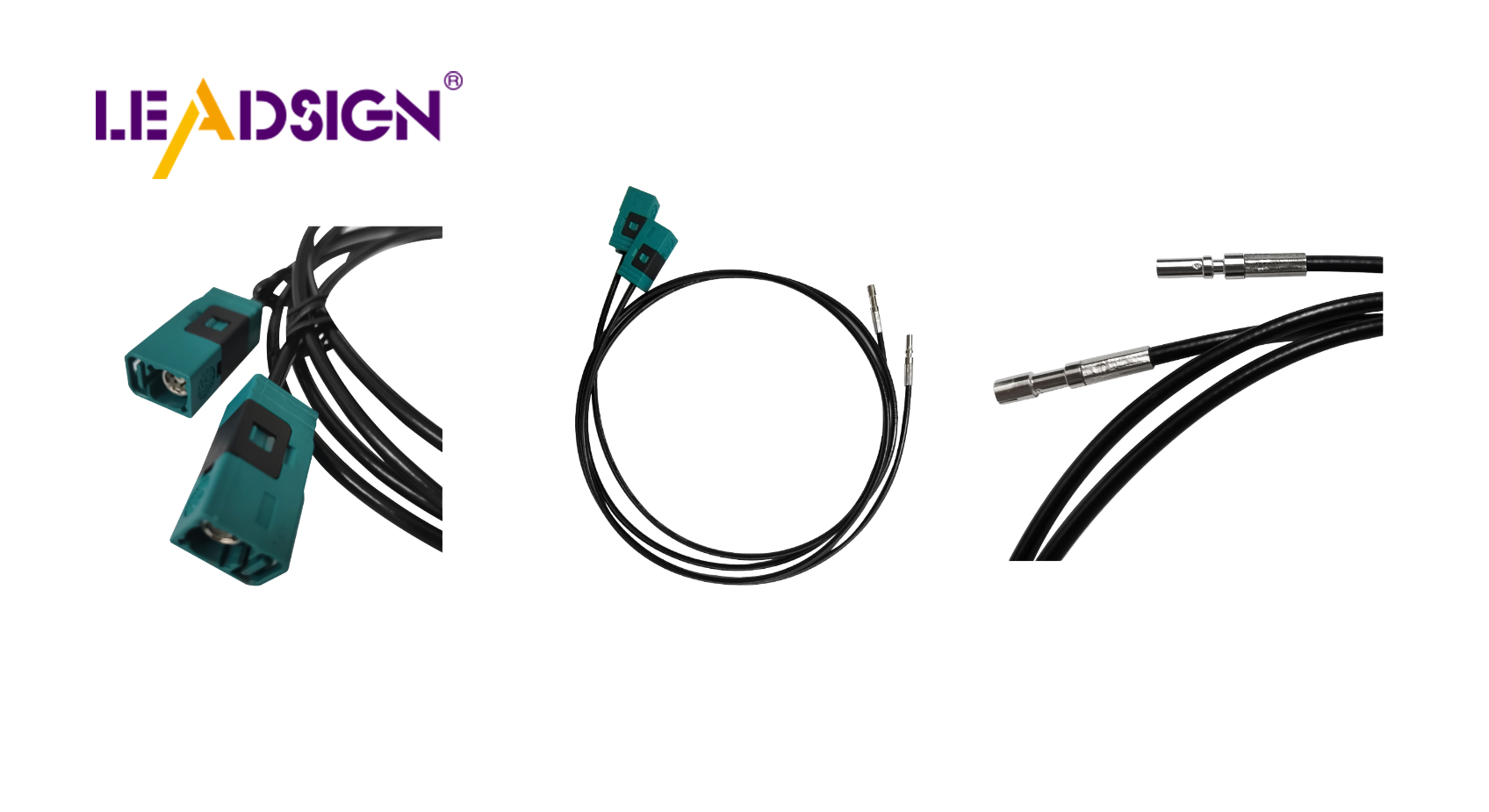

Types of Automotive Electrical Connectors in Use Today

Automotive electrical connectors are important for cars to work well. They help different parts of a car function smoothly. These connectors come in various shapes and sizes, each with its own job.

Traditional Connectors

Traditional connectors have been used in cars for many years. They usually include wire-to-wire and board-to-wire connections. These connectors are simple and dependable. They link ready-made parts or gadgets to the car's wiring system. But, they struggle with the growing complexity of modern vehicles.

Modern Connectors

Modern connectors have changed to fit new car technologies. They have features like being smaller and handling heat better. For example, Molex DuraClik Connectors show this change with their strong PBT housings that hold terminals securely. These connectors can handle tough car environments, working well even when it's hot or shaky. Modern ones also include power adapters for easy access to a car's electric system.

Challenges Faced by Current Connector Types

Even though automotive electrical connectors have improved a lot, they still face some problems that need fixing as technology advances.

Durability Issues

Durability is a big worry for automotive connectors. Cars work in tough places, which means lots of shaking, rusting, and extreme heat can affect them. Connectors must survive these conditions to keep working well. Companies like TE make connectors that meet these tough needs, especially for hybrid and electric cars.

Compatibility Concerns

Compatibility is another issue for current connector types. As cars get more complicated, we need connectors that fit with different systems easily. Various automotive electrical connector types should connect wires, circuit boards, chips, and batteries together smoothly for modern vehicles to run properly.

New Trends in Connector Technology

Making Connectors Smaller

Making automotive electrical connectors smaller is becoming popular. Tiny connectors have many benefits, making them a top choice for new cars.

Advantages of Tiny Connectors

Space Saving: Small connectors take up less room, fitting more parts in tight spaces. This is important where space is limited.

Less Weight: Light connectors help make cars weigh less, improving fuel use and performance.

Better Looks: Small connectors allow sleek designs, making car insides look nicer.

Tech Helping Make Connectors Smaller

New technology helps make automotive electrical connectors smaller. Better materials and ways to make them mean these tiny connectors are strong too. For example, mini rugged connectors are key in air travel, offering light but tough parts for electric engines. They handle rough conditions while working well, perfect for today's cars.

More Smart Connectors Used

Smart connectors are another big trend in automotive electrical connector types. These have cool features that improve how they work in cars.

Features of Smart Connectors

User-Recognition Systems: Smart ones know users, ensuring safe and personal connections.

Self-Diagnosis Capabilities: They find problems and warn users, saving time and money on fixes.

Better Data Transfer: Smart ones move data fast, needed for new entertainment and safety setups.

Uses in Modern Cars

Smart connectors are used in many car systems. They are key in driver help systems (ADAS), allowing sensors to talk with control units easily. In entertainment systems, smart ones send high-quality sound and video, making the experience better for users. Plus, they help connect cars with the Internet of Things (IoT), letting vehicles link with other devices and networks.

Electric cars have changed car connectors a lot. As more people use electric cars, we need special connectors. These must handle more power and heat well.

Electric cars use higher voltages than regular cars. This means they need strong connectors for safe energy transfer. Electric car connectors are made tough to handle high power safely.

Heat is a big deal for electric car connectors. Charging and using electric cars makes lots of heat. Good heat control keeps them working well and lasting longer.

Electric cars have led to new connector ideas. These make charging faster and easier.

Fast charging is important now. It lets electric cars charge quickly with powerful connectors, unlike old ones that can't do this fast.

Wireless charging is a cool new idea too. It charges without touching, using invisible fields to move energy from the charger to the car. This makes it easy and helps connectors last longer by reducing wear.

Future Directions and Innovations

IoT and Connectivity in Cars

IoT technology is changing how car connectors work. These connectors help cars talk to each other easily.

Connectors' Job in Smart Cars

Connectors let different car parts work together. They make sure data moves smoothly from sensors to control units, making cars better. For example, they help driver assistance systems get real-time sensor data for safety. As cars connect more, we need strong connectors to keep up.

Fast Data Transfer

Modern car connectors must move data quickly for connected vehicles. With new entertainment systems and self-driving tech, they handle lots of data fast. This need has led to better connectors that send information quickly and correctly inside the car.

Eco-friendly Car Connectors

As cars go green, eco-friendly connectors are more important. Makers look for ways to cut down on waste using sustainable materials.

Recyclable Materials Use

Using recyclable stuff in making connectors helps sustainability. By choosing materials that recycle easily, makers cut waste and support a circular economy. This helps the planet and matches the goal of lowering carbon footprints.

Energy-saving Designs

Energy-saving connector designs help make cars greener. They lessen energy loss when sending data, helping cars run better. By saving energy with these designs, makers boost electric and hybrid car performance, aiding eco-friendly transport goals.

In short, future car wiring connectors will mix with IoT tech and go green. As cars get smarter and greener, connectors will change too, pushing new ideas in the auto world.

The future of car wiring connectors has some important changes coming. Makers are working on making them smaller, adding smart tech, and using eco-friendly designs. These changes help meet the needs of electric and self-driving cars.

"New connector ideas come from what electric and self-driving cars need."

As cars get more complicated, they will need better connectors for many sensors and systems to talk to each other. This change in connector tech makes cars work better and helps the move towards greener and more connected transport solutions.

See Also

Enhancing Automotive Connectivity with Fakra Connectors in Modern Cars

Maximizing Automotive Data Transfer: Cutting-Edge Connectors and Cables

Transforming Auto Connectivity: Benefits of High-Frequency Modular Connectors

Understanding High-Speed Data Connectors in Auto Manufacturing