Future Directions in Best Automotive Wire Design

The design of automotive wiring is crucial for modern vehicles, particularly in supporting electric cars and advanced smart driving systems. As vehicles become increasingly complex, the demand for lighter and more efficient wiring solutions grows. The automotive industry faces challenges such as achieving eco-friendliness and requiring intricate wiring configurations. Innovations like the HSD PCB Connector enhance connectivity and improve energy efficiency. The integration of smart materials, including those with shape memory or self-repair capabilities, extends the lifespan of wires. These advancements represent the best automotive wire design, benefiting both current and future automotive technologies.

New Trends in Car Wire Design

Lighter Wires in Cars

Why Use Light Wires?

Car makers now use lighter wires. This helps cars use less fuel and go faster. It also means fewer emissions, which is better for the planet. Light wires make cars quicker and easier to handle, especially electric ones.

New Materials for Wires

Scientists are making new wire materials. These are light but still conduct electricity well. They use special mixes that last long and can handle tough weather. Some wires can even fix themselves if they break.

Smart Wire Systems

Connecting with IoT

Cars now have smart wires that connect with the Internet of Things (IoT). This lets car parts talk to each other easily. It helps keep cars safe by spotting problems early.

Better Car Communication

Smart wires help cars communicate better. They work with systems like ADAS and entertainment features needing fast data transfer. Special connectors ensure everything works smoothly, making driving safer and more fun.

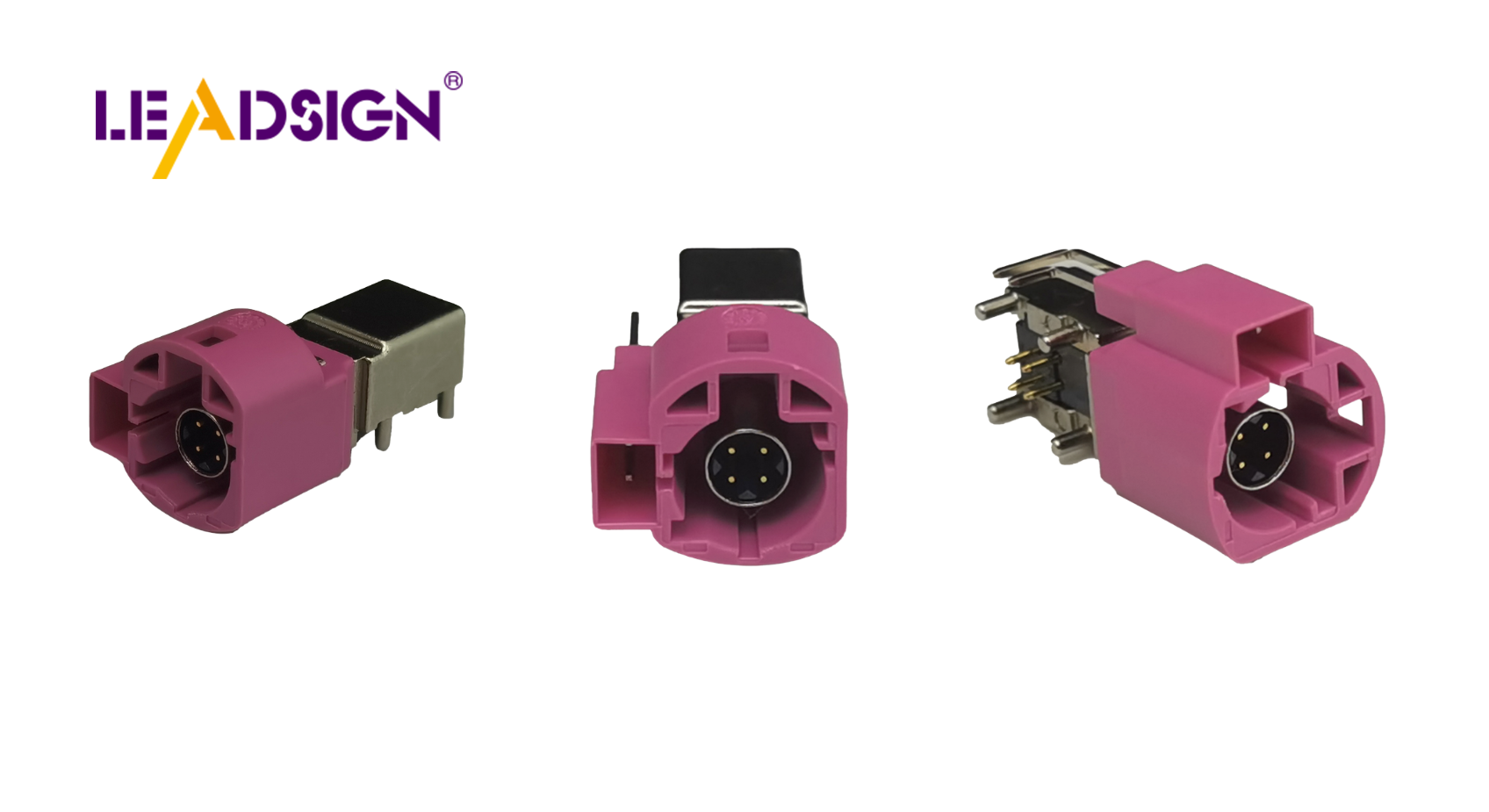

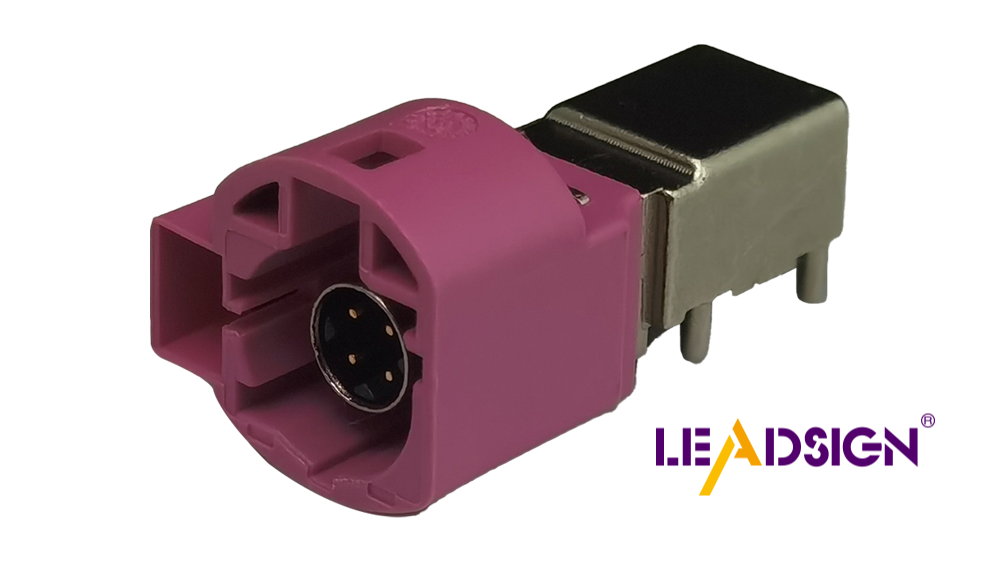

Technological Advancements in HSD PCB Connector

The HSD PCB Connector is a big step forward for car wires. It helps connect things better and work more efficiently. As cars change, they need faster data and strong wires. The HSD PCB Connector does this by giving good connections for many car uses.

High-Voltage Wiring for Electric Vehicles

Safety Considerations

Electric cars need high-voltage wires to work well. Safety is very important here. The HSD PCB Connector has smart safety parts to stop electrical dangers. It has main and extra locks to keep connections safe. This stops accidental unplugs that could be risky. Also, its design stops wrong plugs, making it safer.

Efficiency Improvements

Good wiring helps electric cars run better. The HSD PCB Connector saves energy during use. Its crimp tech keeps cables tight, even when stressed. This means less energy waste, helping cars go farther and perform better. Using these connectors makes cars more efficient and attractive to buyers.

Advanced Insulation Techniques

Thermal Management

Managing heat is key in car wiring systems. The HSD PCB Connector uses special insulation to handle heat well. This stops overheating which can harm parts or slow them down. Keeping the right temperature helps the system work well, even when it's tough outside.

Durability Enhancements

Strong materials make car wires last longer. The HSD PCB Connector uses tough stuff for long-lasting use. These materials stand up to bad weather like heat and shaking roads. This strength means fewer fixes needed, saving money for owners over time.

Market Predictions and Future Outlook

Growth in Electric and Autonomous Vehicles

Impact on Wire Design

Electric and self-driving cars change how wires are made. More of these cars need complex wire setups. Electric cars use high-power systems, needing strong wires. Self-driving cars have smart tech that needs special wiring. Smart materials like those that remember shapes or fix themselves help wires work better. These materials keep wires safe in heat and shaking, making sure they stay connected.

Industry Demand Forecasts

Car makers expect more need for better wires. As more electric and mixed cars come out, complex wiring is needed more. Making wires with machines makes them better and cheaper. This helps meet the exact needs of new cars. The market for car wires will grow a lot because of new tech and car designs.

Regulatory and Environmental Considerations

Compliance with New Standards

Rules make sure car wires are safe and work well. Makers must follow these rules to be allowed to sell their products. High-power electric car systems need good safety steps like strong insulation. The HSD PCB Connector shows it follows these rules by having locks to stop unplugging by accident.

Sustainability Initiatives

Being green is key in future wire design for cars. Using eco-friendly stuff helps cut down on harm to nature when making wires. Light materials help save fuel and cut pollution, which fits with world goals to be greener. Using recyclable parts in wires also helps save the planet.

The future of car wires depends on new trends and tech. Light materials and fast data are needed for self-driving cars. Special wire setups help electric cars handle high voltage safely. Being eco-friendly is important too, with makers using green ways and stuff. These changes make cars better and fit with world green goals. Car companies must use these ideas to stay ahead and help the planet's future.

See Also

Maximizing Automotive Data Transfer: Cutting-Edge Connectors and Cables

Improving Data Transfer: The Significance of High-Velocity Automotive Connectors

The Significance of Fakra Connectors in Automotive Manufacturing

The Benefits of HFM Connectors in Automotive Manufacturing

Transforming Automotive Linkage: The Benefits of HFM Connectors