Finding the Right Types of Wire Connectors Automotive

Selecting the appropriate automotive electrical connectors types for vehicles is crucial. It plays a significant role in ensuring safety and optimal functionality. Factors such as exposure to harmful gases, moisture, and vibrations can lead to connector damage, including rust and deterioration. Understanding the various types of automotive electrical connectors available is essential. Each type offers unique advantages and varying durability. This knowledge empowers you to make informed decisions, ultimately enhancing the reliability and efficiency of your car's electrical systems.

Understanding Car Wire Connectors

When you work with car wire connectors, there are many choices. Each type has a special job and benefits. Let's look at some common types and how they are used.

Types of Wire Connectors

Butt Connectors

Butt connectors join two wires in a line. You use them to make a wire longer. They connect well and are easy to put on. These connectors fix or extend wires in cars.

Ring Terminals

Ring terminals have a round end that fits over bolts or screws. You use them to attach wires to posts or studs. This connector makes strong connections, good for grounding in cars.

Spade Terminals

Spade terminals, also called fork terminals, have split ends. You can quickly attach and remove them from spots. They are great for places where wires need frequent changes, like fuse boxes in cars.

Bullet Connectors

Bullet connectors have male and female ends that snap together easily. You use them for fast connections. They are often found in car lights for easy setup and removal.

Materials Used in Wire Connectors

The material of a connector affects how it works and lasts:

Copper

Copper is popular because it conducts electricity well. It transfers power efficiently and resists rusting. Copper connectors are used in high-performance car parts.

Aluminum

Aluminum is light and cheap but rusts easier than copper. It's used where less strength is needed in cars.

Brass

Brass mixes copper and zinc for good conductivity and rust resistance. It's used where durability is important, like engine areas.

Insulation Types

Insulation protects the connector from damage:

Nylon

Nylon insulation bends easily and resists wear. It protects against chemicals and water well, good for tough conditions.

PVC

PVC insulation is cheap but protects against water and chemicals too. It's fine for normal car uses without extreme conditions.

Heat Shrink

Heat shrink insulation seals tightly around the wire, protecting against water damage best of all. It's used where reliability matters most in cars.

Knowing these types helps you choose wisely for your car's safety.

Picking the Right Connector for Your Car

Choosing the right wire connectors helps your car work well. Think about a few things to decide best. Let's look at what you need to know.

Checking Electrical Needs

Know your car's electrical needs. Check how much power and voltage the connectors can handle.

Power Rating

Power rating shows how much electricity a connector can take safely. Pick one that meets or beats your car's power needs. A weak connector might overheat and fail.

Voltage Rating

Voltage rating is the highest voltage a connector can handle. Choose one that fits your car's system to avoid problems. Make sure it matches for safety and good performance.

Thinking About Environment

Weather affects how connectors work in cars. Look at temperature and water resistance when picking them.

Temperature Resistance

Hot or cold weather changes can hurt connectors. Get ones that handle your car's temperature range well. High heat resistance keeps them working in tough spots.

Water Resistance

Water can rust and harm connectors. Pick ones that stop water from getting in. This matters if your car faces wet places, keeping connections strong.

Looking at Mechanical Needs

How strong a connector is also matters for cars. Check vibration resistance and toughness for good connections.

Vibration Resistance

Cars shake when moving, which can loosen connectors. Choose ones with high vibration resistance to keep them tight, especially on bumpy roads or fast drives.

Toughness

Toughness shows how long a connector lasts without breaking down. Pick strong materials for longer life, saving time and money on fixes.

By thinking about these things, you pick the right wire connectors for your car, making it run better.

Explore Different Choices

When using car wire connectors, you have options. Each choice has its own benefits. Let's look at these to help you decide.

Soldering vs. Crimping

Picking soldering or crimping affects how well your car wires work. Both ways are good.

Why Soldering is Good

Strong Connection: Soldering makes a strong link between wires. It keeps connections steady against shaking.

Conductivity: Soldering helps electricity flow better. The copper used in soldering improves power movement.

Durability: Soldered links last long in tough conditions. They resist water and temperature changes well.

Why Crimping is Good

Ease of Use: Crimping is easy to do. You can join wires fast without many tools or skills.

Flexibility: Crimped links come apart easily if needed. This helps when fixing or changing parts.

Reliability: Crimping gives steady results every time. It ensures tight fits, preventing loose wires.

Quick Connectors vs. Traditional Connectors

Car wire connectors include quick and traditional types, each for different needs.

Benefits of Quick Connectors

Speed: Quick connectors save time by connecting fast, great for regular checks.

Convenience: These are simple to use with little effort needed.

Versatility: Quick connectors fit many uses in cars.

Benefits of Traditional Connectors

Stability: Traditional ones hold tight even in bad conditions.

Cost-Effectiveness: They are often cheaper, saving money on car fixes.

Compatibility: Traditional types fit many car systems and parts.

Knowing these helps pick the best way for your car's needs, whether it's soldering, crimping, quick or traditional connectors, each affects your car's electric system performance and trustworthiness.

Choosing the right wire connectors for your car is important. They keep you safe and help the car work better. Here's a quick summary:

Key Points: Know different connector types, materials, and insulation. Check electrical, environmental, and mechanical needs.

Importance: Good connectors stop system failures and save on repairs. They make your car more reliable and efficient.

"Having the right electrical connectors can make for a reliable system operation."

Think about everything before choosing. Your choice affects how your car works and feels. Make smart choices for safer and better driving.

See Also

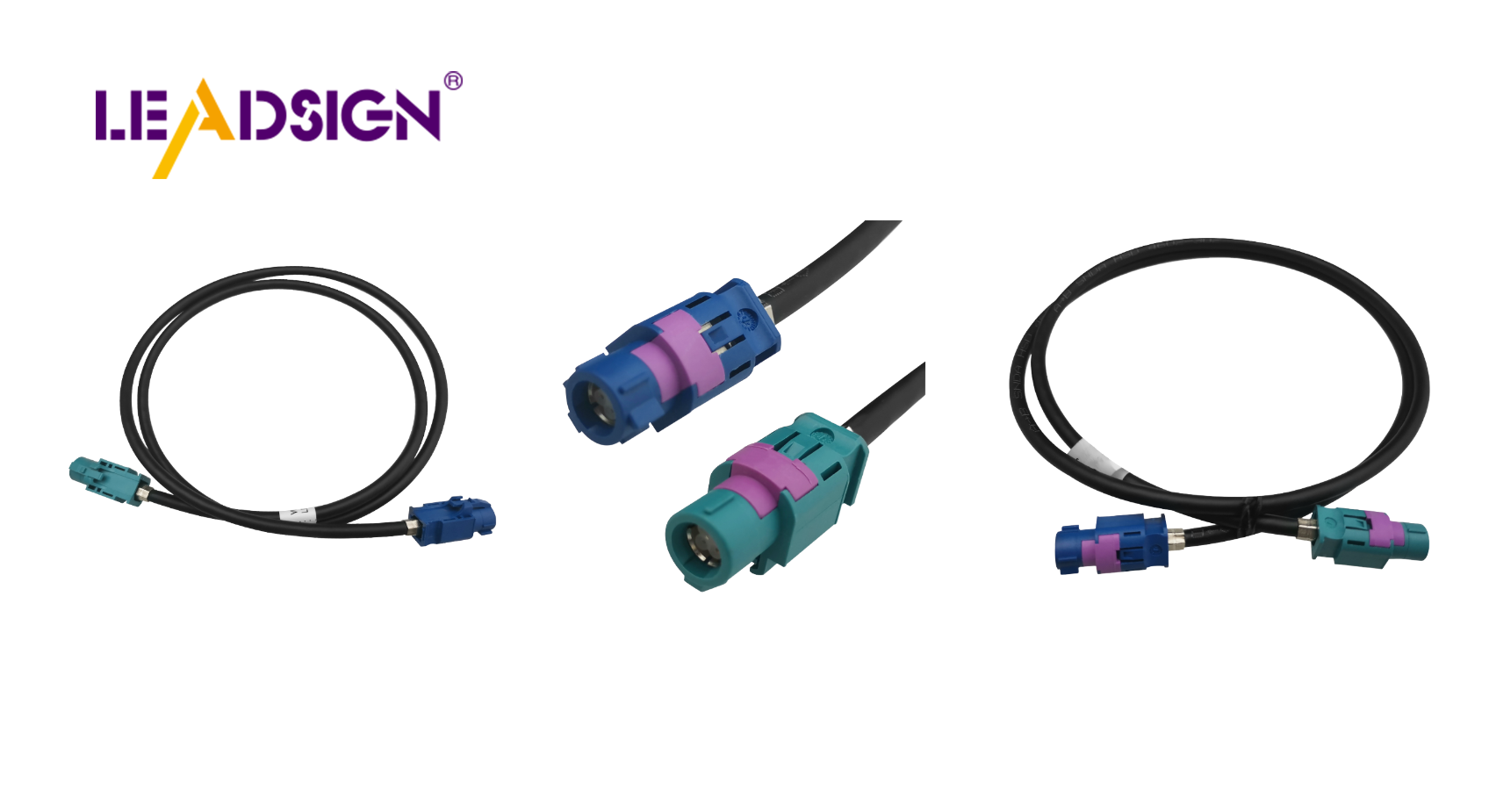

Benefits of HFM Connectors for Automotive Sector

Significance of Fakra Connectors in Auto Sector

Vital Role of FAKRA Connectors in Auto Uses