Are Fakra connectors waterproof?

LEADSIGN electronics offers FAKRA PCB Connectors, which are essential in various industries for secure data transmission. The importance of waterproofing in these connectors cannot be overstated, as it ensures durability and functionality in challenging environments. These connectors are particularly beneficial for automotive, mobile communication, and electronic devices, maintaining stable connections even under adverse conditions. LEADSIGN electronics provides a range of FAKRA PCB Connectors with cable options (straight, right angle) and standardized housings (single, double, triple, quad) to suit diverse applications. FAKRA connectors enhance the performance of modern technology.

Understanding Fakra Connectors

Definition and Purpose

What are Fakra connectors?

Fakra connectors are special Fakra connectors are special. They are used in cars. They help send signals reliably. Fakra connectors have a unique design. This design stops wrong connections. They meet industry rules.

Common uses in automotive and other industries

Car makers use Fakra connectors a lot. They help with GPS systems. They improve radio connections. Fakra connectors work with infotainment systems. They allow mobile communication. They're important for RF Bluetooth tasks. Fakra connectors are used in car sensors.

Design and Construction

Materials used in Fakra connectors

Fakra connectors use strong materials. Often, they have tough plastics. Metal parts are also included. This makes them last long and work well. They resist weather effects and tough conditions, keeping signals clear.

Structural features contributing to durability

Fakra connectors have strong designs. They include locks for safety connections. The housings have colors for easy spotting. Waterproof seals keep out water, ensuring reliable performance.

Waterproof Abilities of Fakra Connectors

Design Features for Keeping Water Out

Sealing Methods

Fakra connectors have special seals. Rubber rings make them tight. These rings stop water from getting in. O-rings help seal better. They ensure a snug fit. Fakra connectors stay safe in wet places.

IP Ratings and Why They Matter

Fakra connectors often get IP ratings. An IP67 rating blocks dust completely. It means they can be underwater safely. Some have an IP69K rating too. This means they resist strong water sprays. IP ratings show how waterproof they are.

Testing and Rules

Rules for Waterproof Testing

Rules make sure tests are reliable. Tests follow set steps. These steps mimic tough conditions. Standards include dunking tests. Other tests use strong water sprays too. Following rules ensures good performance.

How Fakra Connectors Are Tested for Water Safety

Fakra connectors face tough tests. Engineers put them in water tanks. Pressure checks mimic real-life situations. Strong sprays test their strength too. Engineers check how well they work after testing them, showing they're waterproof as expected.

Uses and Limits

Common Uses

Car Uses

Fakra connectors are key in cars. They help connect radio antennas. Fakra connectors make GPS work well. They improve car TV systems too. Fakra connectors allow phone calls in cars. They help with Bluetooth and Wi-Fi tasks. Fakra connectors let car keys work without touching them. They aid in heating systems for cars. Fakra connectors boost sensors to detect things.

Other Industries Using Fakra Connectors

Fakra connectors are used outside of cars too. Phone companies depend on them for good links. Factories use them in machines that work by themselves. Hospitals need them for accurate data sharing. Planes use them for safe connections. The military relies on them for communication.

Limits and Things to Think About

Environment Impacting Performance

Weather can change how Fakra connectors work. Very hot or cold places might be a problem. Humidity can test their waterproof skills. Dust might mess up connections, and shaking can weaken them over time.

Possible Problems in Certain Situations

Some places show where Fakra connectors fall short. Saltwater can wear them down if exposed too long. Sunlight may harm their materials over time, while chemicals could damage them inside out, and hard hits might break them physically, so regular checks keep them working well.

LEADSIGN Electronics and Fakra PCB Connectors

Product Offerings

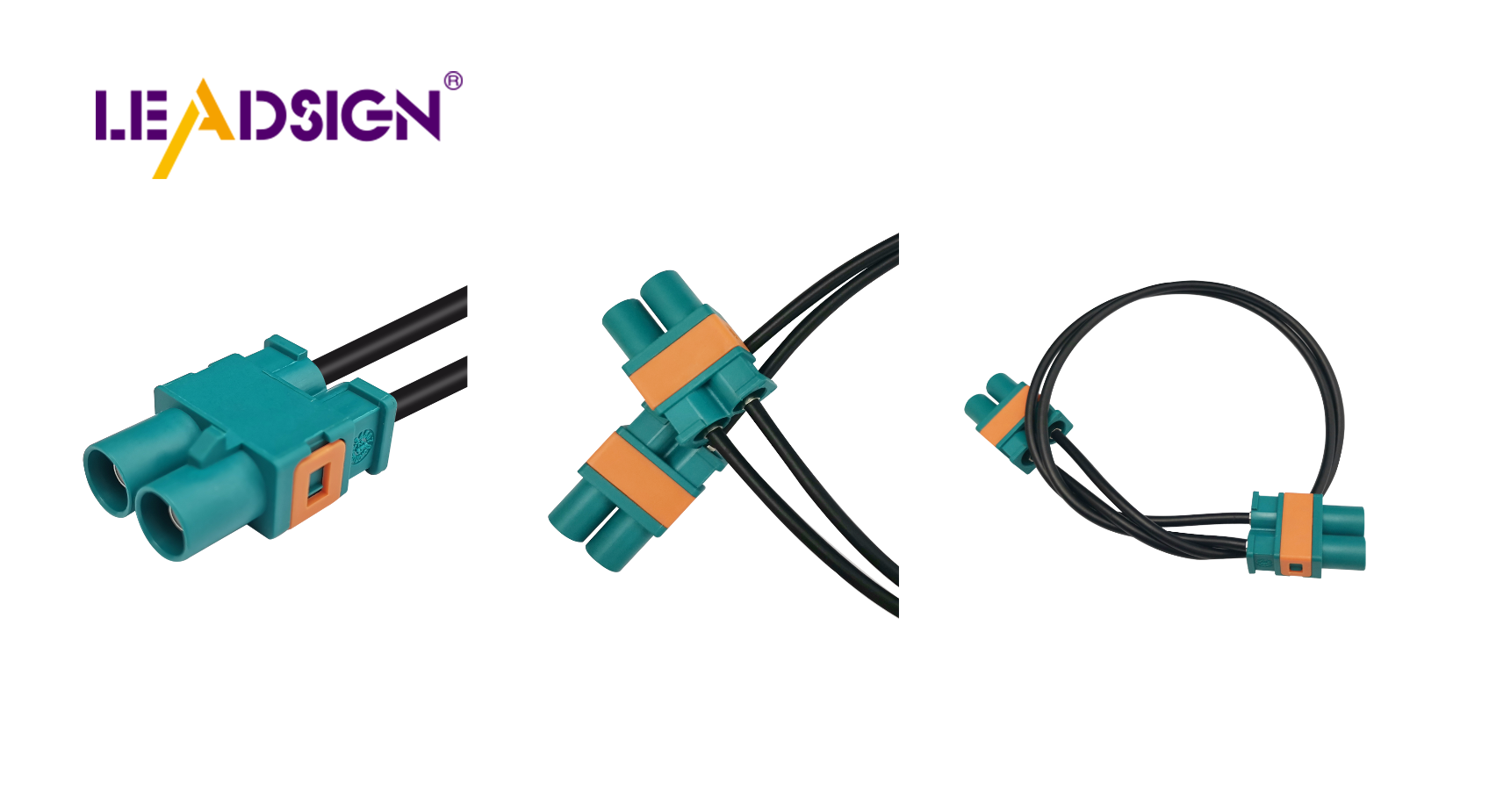

Cable connectors (straight, right angle)

LEADSIGN makes top FAKRA PCB Connector Cable connectors. They come in straight and right-angle types. These designs help send signals well in cars. Straight ones give a direct signal path. Right-angle ones fit in small spaces. Both keep strong links in different situations.

Standardized housings (single, double, triple, quad)

The company has standard housings for FAKRA PCB Connectors. Choices are single, double, triple, and quad housings. Each fits certain setups. Single is for simple uses. Double supports two connections. Triple and quad manage complex systems. These housings make connections safe and tidy.

Customized Solutions

Tailored designs for specific needs

LEADSIGN electronics offers custom solutions. Designs match special customer needs. Custom work helps fit with current systems better. Engineers talk with clients to know their needs well. This teamwork leads to exact and useful solutions. Custom designs boost how things work.

Integration with existing systems

Fitting into current systems is important here. LEADSIGN electronics makes sure everything fits smoothly together. Engineers check present setups for best fitting-in ways. This plan cuts down problems when setting up new parts. Joined systems improve how everything works together well.

Fakra connectors are very good at keeping water out. Engineers make them with seals and IP ratings to stop water. They work well in cars and tough places. These waterproof parts help Fakra connectors do well in wet spots. Fakra connectors are a strong choice for waterproof needs. Use Fakra connectors for projects needing safe and strong links in hard conditions.

See Also

An In-Depth Look at FAKRA Male Connectors

Deciphering FAKRA Connectors: An Extensive Overview

The Significance of FAKRA Connectors in Auto Industry