FAKRA Connectors and Their Influence on Custom Cable Harness Performance

FAKRA connectors are important for car signal sending. They are made to handle tough car conditions. FAKRA connectors keep connections steady and reliable for wireless systems. Keeping good signals in custom cables is key. Design rules like ISO20860-1 and USCAR-18 set connector sizes. Good signal sending is needed for GPS and Bluetooth. High-quality FAKRA connectors help custom cables work well.

Understanding FAKRA Connectors

Design and Structure

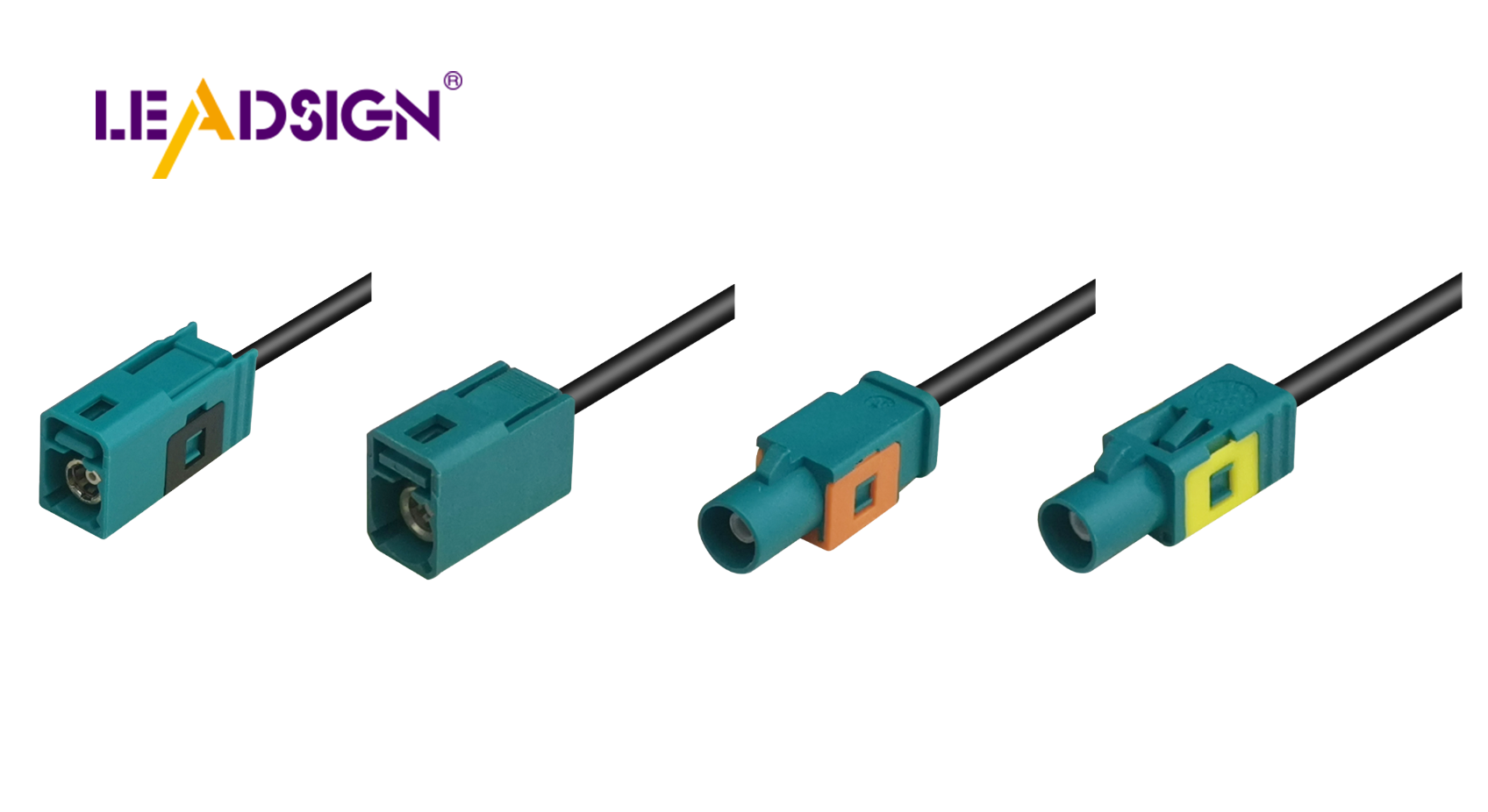

FAKRA connectors are key in cars. They have a special design for good work. Different colors help identify them easily. Each color shows what it’s used for, stopping mix-ups when installing. They also lock in place to stop them from coming loose.

Color Coding and Mechanical Features

Colors make putting FAKRA connectors together easy. Grand-Tek has 13 colors of FAKRA shells. Each color is for something different. The connectors have parts that fit only one way. This stops wrong connections. Colors and these parts make FAKRA connectors very reliable.

Compliance with Industry Standards

FAKRA connectors follow many rules. These include ISO 20860-1 and USCAR-17 standards. Following these rules means they fit with car makers worldwide. They meet tough tests to work well in cars, ensuring they last long even in hard conditions.

Performance Parameters

FAKRA connectors work really well in cars, sending signals smoothly. They handle high-frequency signals, making them good for many uses.

Frequency Range and Impedance

FAKRA connectors work over a wide frequency range, good for GPS, radio, and Bluetooth use. They keep the signal steady by holding impedance levels constant, which helps avoid losing signals.

Temperature and Waterproof Ratings

FAKRA connectors do great in tough spots, working from -40°C to +105°C temperatures so they can be used anywhere in cars without problems from heat or cold. They're waterproof too, keeping water out so they last longer.

Uses of FAKRA Connectors

Cars

Radio and Tech Systems

FAKRA connectors are important in cars. They help with radio and tech systems. These connectors keep signals strong for car communication. They support high-frequency signals, which is needed for clear sound. This makes them great for new cars using 5G and V2X tech. The colored plastic of FAKRA connectors makes them easy to spot and use, lowering mistakes when putting them together.

No-Key Entry and Bluetooth

FAKRA connectors are also key for no-key entry and Bluetooth in cars. These systems need good signal flow to work right. FAKRA connectors meet tough car rules, making sure these systems run smoothly. Their strong build keeps signals steady, perfect for adding no-key entry and Bluetooth in cars. They match with many car parts, boosting system performance.

Tough Places

Fast Industrial Cameras

FAKRA connectors aren't just for cars; they work in tough spots too, like fast industrial cameras. These cameras need solid links to send data well. FAKRA connectors are strong enough for hard conditions, fitting industrial needs. They handle high-frequency signals so camera data is clear and without problems.

Device-to-Device Modules

Device-to-device modules also use FAKRA connectors. These modules let machines talk in different fields, needing strong links. FAKRA connectors give the support needed for smooth talks between devices. They're built to handle tough weather changes and wetness, making them perfect for device modules working in hard places.

Impact on Signal Transmission

Signal Integrity and Impedance Matching

FAKRA connectors help keep signals clear. Engineers use good designs and materials. This stops interference and makes signals better. The connectors match impedance well for strong signals.

Insertion loss can weaken signals. Reducing it keeps signals strong at different frequencies. This is why FAKRA connectors are great for GPS, radio, and Bluetooth. They lock in place to stop signal problems from shaking.

Role in Custom Cable Harness Performance

FAKRA connectors improve cable harness work a lot. They offer flexible designs for easy setup. These connectors fit many setups, helping car systems adapt.

Making FAKRA connectors needs care and quality checks. Makers follow strict rules for reliability. Testing ensures each connector works right in tough places.

Automation in FAKRA Connector Assembly

New Assembly Technology

Semi-automatic and Fully Automatic Systems

New tech has changed how FAKRA connectors are made. Factories use semi-automatic and fully automatic systems now. Semi-automatic systems help workers by doing repeat tasks. This cuts mistakes and keeps things steady. Fully automatic systems do all the work without people. They make sure connectors are made fast and right.

Benefits of Automation in Production

Automation helps a lot in making FAKRA connectors. Machines make more connectors faster, meeting big orders easily. Quality gets better too because machines don’t mess up like people can. It also saves money by needing fewer workers but making more stuff. Using machines to build connectors helps companies grow by working better and smarter.

"Don’t let old ways slow you down. Use our new Connector Assembly Line for better work, quality, and savings that help your business grow.

FAKRA connectors make car signals better. They keep connections steady and reliable. These connectors meet high-frequency needs. Good design and testing help them work well. FAKRA connectors are key for wireless and self-driving cars. In the future, they will need to handle faster data and less delay. Their role in car tech will grow, helping with new communication and control systems.

See Also

Exploring the Significance of Fakra Connectors in Auto Sector

Discovering the Advantages of Fakra Auto Connectors

The Significance of FAKRA Z Connectors in Auto Uses