Factors to Consider When Selecting Auto Harness Connectors

Picking good auto harness connectors keeps your car safe. Bad connectors might cause electrical problems or system issues. This can be dangerous. Good connectors stay secure and help avoid accidents. Always choose strong and matching connectors to keep your car working well.

Key Takeaways

Pick connectors that fit your car's power needs to avoid overheating and stay safe.

Use connectors with the correct size and locks to keep connections strong, even in tough situations.

Choose well-known brands and look for quality labels to ensure your connectors last and work well.

Electrical Specifications

Current and Voltage Ratings

When picking connectors, check their current and voltage limits. These limits show how much electricity they can handle safely. Using connectors with low limits can cause overheating or fires. Always match the connector limits to your car's electrical needs. This keeps your car safe and parts undamaged.

Wire Size Compatibility

The wires in your harness must fit the connectors. If wires are too big or small, they might not stay connected. Loose wires can stop power or signals from working. Check the connector details to match your wire size. This keeps the connection strong and reliable.

Connector Resistance and Conductivity

Low resistance and good conductivity are very important. High resistance can lower voltage and hurt your car's systems. Choose connectors made of materials like copper or gold-plated ones. These materials save energy and keep power and signals working well.

Environmental Considerations

Temperature Tolerance

Auto connectors must handle very hot and cold temperatures. High heat can damage connectors and shorten their life. Most connectors work between -60°C and 200°C. Check the temperature range to match your car's needs. Cars in cold areas need freeze-proof connectors. Cars in hot places need heat-resistant ones. This keeps the wiring working and signals clear.

Vibration and Shock Resistance

Cars face bumps and shakes, especially on rough roads. These movements can loosen or break connectors. Pick connectors with strong locks and materials that absorb shocks. Vibrations can wear out the wiring over time. Strong connectors last longer and work better. This is extra important for off-road or high-performance cars.

Ingress Protection (IP) Ratings

IP ratings show how well connectors block dust and water. The first number shows dust protection, and the second shows water resistance. For example, IP67 connectors block all dust and can handle short water dips. Many car parts like lights and cameras need IP67 or better. Choose connectors with the right IP rating for your car. This keeps wires safe from dirt and water, making them last longer.

Mechanical Features

Connector Size and Circuit Density

Modern cars need small and efficient wiring solutions. Smaller connectors with more circuits have many benefits:

Lightweight designs help cars use less fuel.

Easier to install in tight car spaces.

Can do more tasks in small areas.

Support fast data transfer for advanced car systems.

Work with different devices for smooth operation.

When picking a high-density connector, check your car's wiring layout. Small connectors save space but still work well. This is very useful for cars with advanced screens or sensors.

Locking Mechanisms for Secure Connections

Good locks stop wires from coming loose and keep them working. Different locks are made for different car uses. Here's a table of common locking types:

Locking Mechanism | How It Works | Where It's Used |

|---|---|---|

Bayonet Lock | Twist to lock; handles shocks and shakes. | Power or signal wires. |

Latch | Spring holds it tight; works in many places. | Outdoor uses. |

Lever Lock | Clamp clicks in place; strong and sturdy. | Factories and transport. |

Push-Pull Lock | Squeeze to unlock; avoids accidental pulls. | Quick medical setups. |

Screw Lock | Screws in tightly; keeps out dirt and water. | Round or square connectors. |

Snap-in Lock | Easy and fast; not as strong. | Testing tools. |

Pick a lock type based on your car's needs. For example, bayonet locks are great for bumpy rides, while screw locks seal tightly.

Engagement Force and Ease of Use

How hard it is to connect or disconnect wires matters. Low force makes setup easier, especially with tricky wiring. But the connector should still stay secure. Look for connectors that are easy to use but lock tightly. This makes assembly fast and reliable.

Material and Build Quality

Plastic vs. Metal Housings

The housing material of connectors is very important. Plastic and metal are the most common choices. Each has its own advantages for different uses.

Material | Benefits |

|---|---|

Plastic | |

Metal | Best for tough jobs like farm or construction vehicles. |

Plastic housings, like those made of nylon, are tough and resist car fluids. They protect wires from water, dirt, and chemicals. Metal housings, like stainless steel, are stronger and resist rust. They work well in rough places with lots of impacts.

Corrosion Resistance and Weatherproofing

Rust can damage connectors and mess up wiring. Metal housings, especially stainless steel, resist rust well. This makes them great for wet or salty areas. Plastic housings are lighter but don’t handle rust as well.

Weatherproofing is also very important. Many connectors have seals to block water and dirt. These seals help them last longer, especially outside on things like headlights or GPS. Always check for weatherproofing to keep your wires safe from damage.

Durability and Longevity

How strong connectors are affects how long they last. Plastic ones are less strong and can break under heavy hits. Metal ones are tougher and last longer in hard conditions.

Feature | Plastic Shell Connectors | Metal Shell Connectors |

|---|---|---|

Durability | Less strong, may break under heavy hits | Stronger, handles more stress |

Corrosion Resistance | Not great against rust | Resists rust better |

Environmental Adaptability | Not good for rough places | Works well in tough environments |

Pick connectors that fit your car’s needs and environment. Strong materials help your wires work well, even in tough spots.

Application-Specific Needs

Compatibility with Vehicle Type

The right connectors depend on your vehicle type. Cars, trucks, and motorcycles have different wiring needs. Motorcycles need small connectors because space is tight. Trucks need strong connectors for higher power use. Always check if the connectors fit your vehicle's wiring. This ensures they work properly and last longer.

Purpose-Specific Requirements

Vehicles have different needs based on their use. Off-road vehicles deal with mud, water, and bumps. They need connectors with strong locks and water protection. Sports cars need connectors that keep signals clear at high speeds. These connectors also support systems like GPS and screens. Picking the right connectors for your vehicle's purpose makes them last longer and work better.

Examples of Automotive Connector Systems

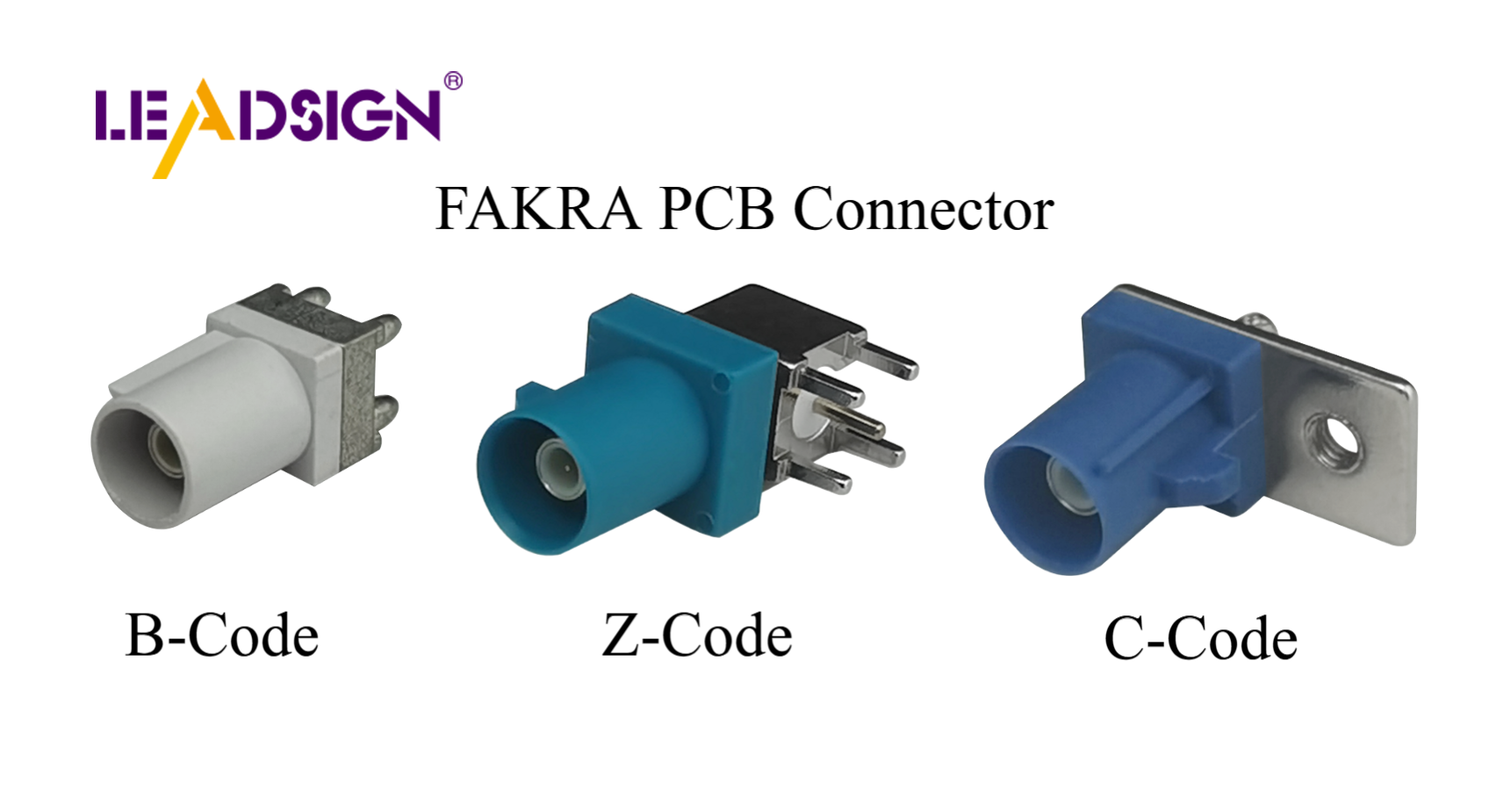

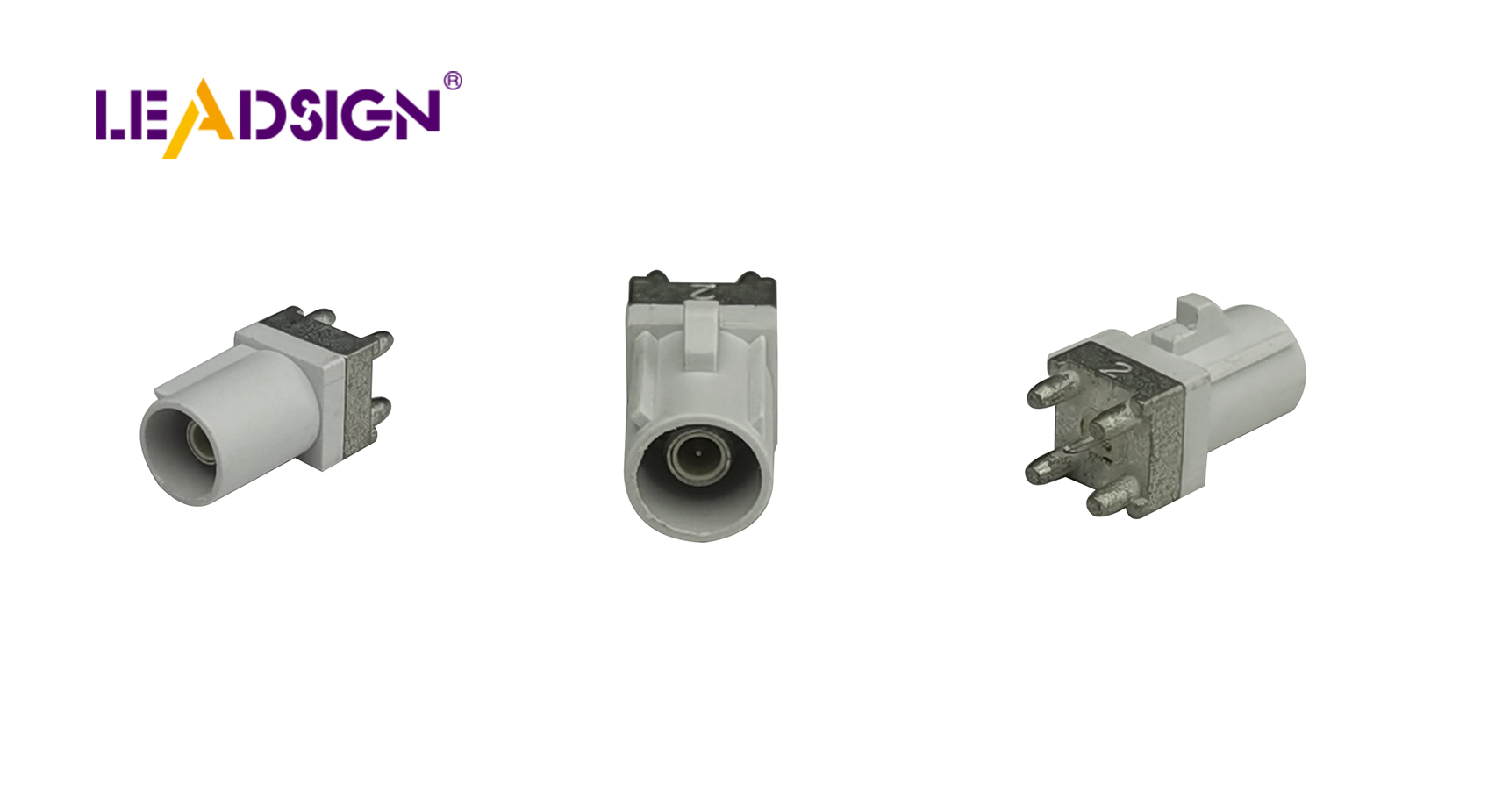

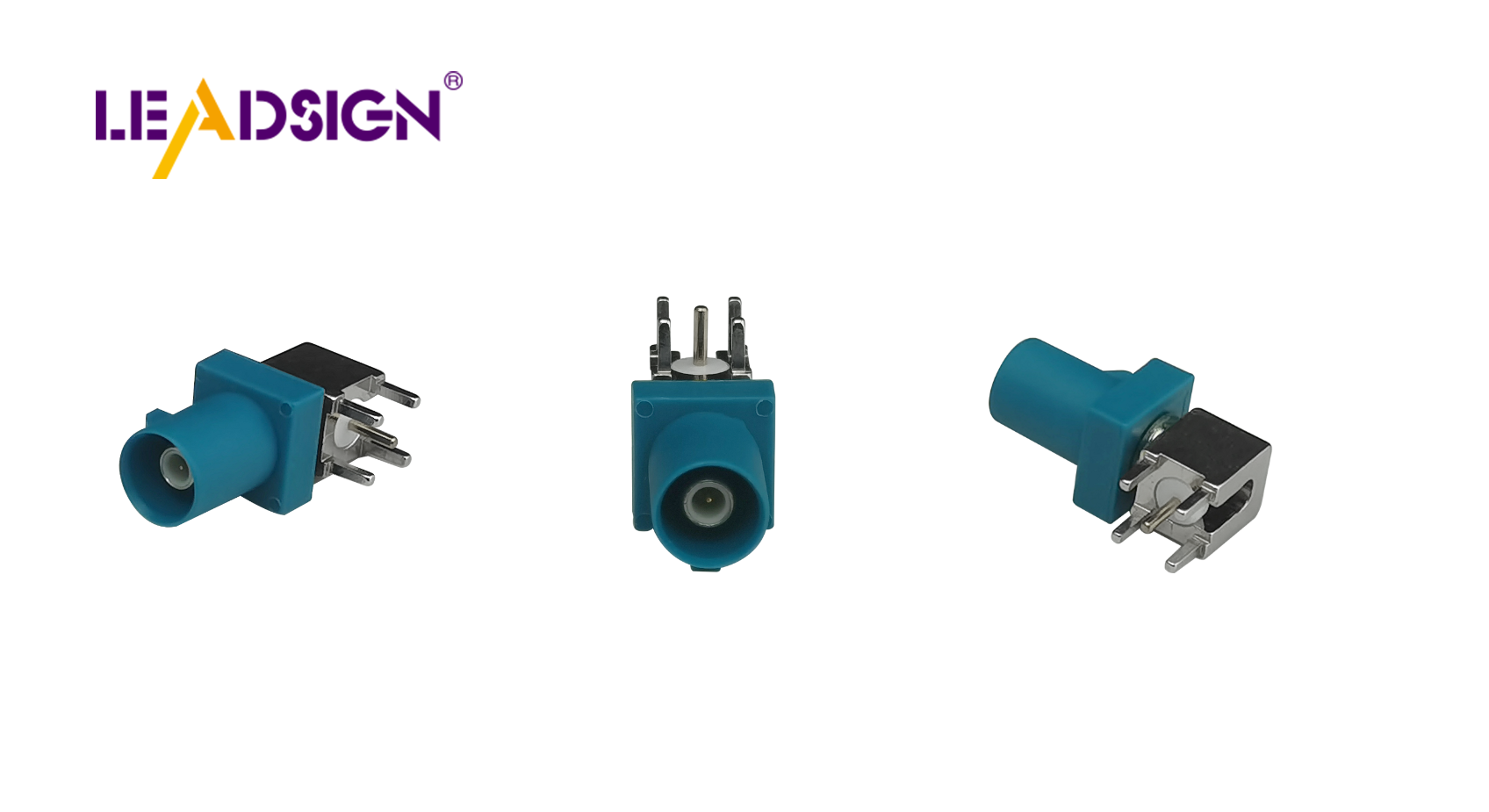

Some connectors are made for specific uses. For example:

Connector Type | Application | Description |

|---|---|---|

GPS, Antennas, Audio Systems | Help send signals smoothly between different systems. |

Other examples include USB and Type-C connectors. These are used for charging phones and transferring data in cars. They work well with mobile devices and transfer data quickly. FAKRA connectors are great for GPS and infotainment. They are weatherproof and handle high-frequency signals. Choosing the right connectors improves your car's features and keeps them reliable.

Supplier and Brand Recommendations

Why Trusted Brands Matter

Picking connectors from trusted brands keeps your car safe. These brands make high-quality products by following strict rules. They also test their products to avoid electrical problems. Brands like Molex, TE Connectivity, and Delphi Automotive are known for being strong and reliable.

Brand | Key Features |

|---|---|

Molex | Strong and reliable, trusted by car experts. |

TE Connectivity | Works in tough conditions, easy to install, many sizes. |

Delphi Automotive | Sealed for safety, resists rust and shaking, handles heat. |

Using these brands helps your car's connectors work well in all conditions.

Standards and Certifications to Look For

Standards and certifications show that connectors are safe and good quality. Look for labels like IATF 16949 and ISO 9001 for quality checks. Other standards like ISO 14001 and ISO 45001 focus on safety and the environment.

VDA (For German car makers)

Certification/Standard | What It Means |

|---|---|

IATF 16949 | Checks quality for car parts |

ISO 9001 | Ensures good quality management |

ISO 14001 | Protects the environment |

ISO 45001 | Keeps workers safe |

Following these standards makes sure your connectors are safe and last long.

Where to Buy Good Connectors

Buying from trusted suppliers has many benefits. Good suppliers deliver on time and keep quality high. They also help save money by managing stock well.

Benefit | Why It’s Important |

|---|---|

Strong Partnerships | Good suppliers and buyers work together to succeed. |

Always in Stock | Reliable suppliers have parts ready, even during shortages. |

Saves Money | Buying in bulk keeps costs low and manageable. |

Quality and Fast Delivery | Trusted suppliers always provide good products on time. |

Choosing reliable suppliers avoids delays and ensures your connectors meet your car's needs.

Picking the right auto harness connectors keeps your car safe. Good connectors stop electrical problems and system failures. Always check if connectors match your car's power, environment, and use. Buying from trusted brands and following standards ensures they last. Avoid errors like reusing old connectors or using wrong wire sizes.

Choosing quality and the right fit helps your car work well and stay safe.

FAQ

What do auto harness connectors do?

Auto harness connectors join electrical parts in cars. They help power and signals move properly between things like lights, sensors, and screens.

How can I pick the right connector for my car?

Choose connectors that fit your car's power, environment, and use. Look at details like voltage, heat limits, and locks to ensure they match.

Is it okay to reuse old connectors?

Using old connectors can be unsafe. Damage can lead to bad connections or failures. Always pick new, good-quality connectors for safety and better performance.

See Also

Why FAKRA Connectors Are Crucial for Automotive Use

Understanding the Advantages of Fakra Connectors in Cars

Enhancing Automotive Performance with HFM Connector Technology

Significance of FAKRA Connectors in Automotive Manufacturing