Exploring FAKRA Connectors in Industrial Settings

FAKRA RF Connector is important in factories. These connectors make sure connections are safe and strong. Car makers first used FAKRA connectors. Engineers made these connectors to fit certain needs. Color codes and special shapes stop wrong matches. FAKRA connectors work well with high frequencies and last long. Factories gain from these good features. FAKRA connectors improve communication tools and make equipment reliable. Industries use FAKRA connectors for smooth work.

Understanding FAKRA Connectors

Design and Mechanism

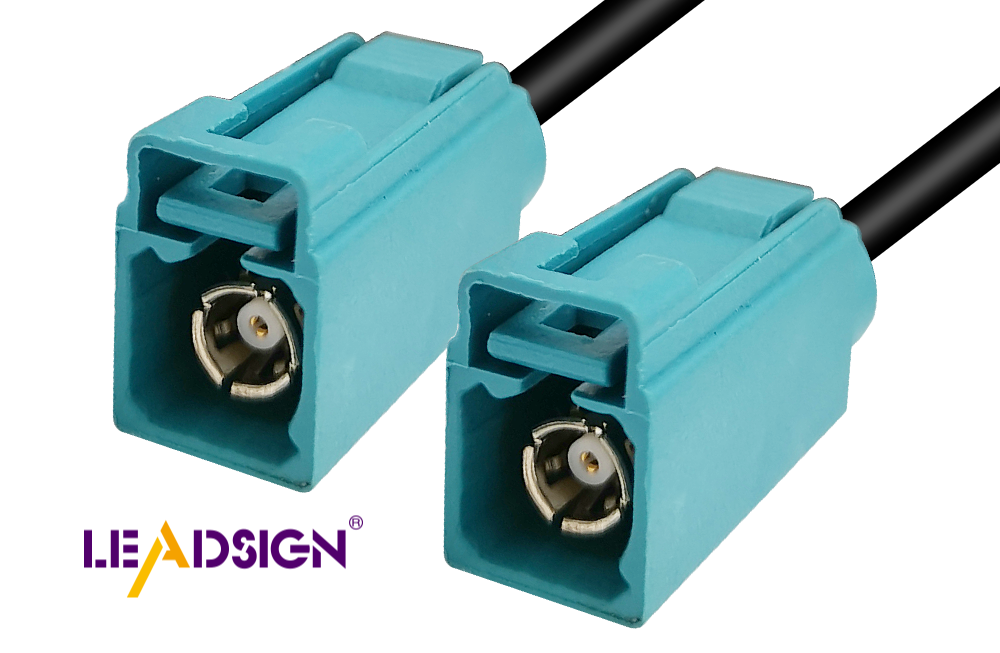

Plug and Jack Design

Engineers make FAKRA connectors carefully. The plug fits tightly with the jack. Each connector has its own shape. This stops wrong connections. Strong materials make it last long. It works well with high frequencies. Factories like this strong connection.

Color-Coding and Key-Coding System

FAKRA connectors use colors to show their job. Each color means something different. This makes setup easy. Workers can spot them quickly. Keys add extra safety by stopping mistakes. Industries trust this for smooth work.

Performance Specifications

Frequency Range and Impedance

FAKRA connectors work over many frequencies. Engineers design them to work best. They match industry rules to cut signal loss. Factories need steady signals for tasks. These connectors help in many jobs.

Temperature and Voltage Ratings

FAKRA connectors handle hot and cold places well. Engineers test them in tough spots. Voltage ratings keep things safe from high power levels, too. Factories trust their strong build for hard work.

Types and Generations of FAKRA Connectors

Different Kinds and Setups

Ways to Attach and Connect

FAKRA connectors have many ways to attach. Engineers pick panel, bulkhead, or PCB mounts. Each mount keeps connections safe for different uses. You can crimp, solder, or screw contacts. These choices make sure they work well in different places. Factories like these flexible options.

Straight and Bent Designs

FAKRA connectors come in straight or bent shapes. Straight ones connect directly for simple setups. Bent ones save space where it's tight. Engineers choose based on space needs. These designs help fit in factories.

Changes Over Time

From GEN 1.0 to GEN 4.0

FAKRA technology has changed over time with four versions. GEN 1.0 had basic car features first. GEN 2.0 got tougher and handled more frequencies better. GEN 3.0 made signals clearer with less noise. GEN 4.0 is fast for sending lots of data quickly now.

Uses for Each Version

Each FAKRA version is good for certain jobs. GEN 1.0 helps with simple GPS systems in cars first off the bat! GEN 2.0 works well with car radios and safety tools too! GEN 3.0 fits high-speed cameras and smart devices best! Finally, GEN 4.o connects machines together super fast!

Uses of FAKRA Connectors

Car Uses

GPS and Telematics

FAKRA connectors are key in car systems. They help send data from the GPS to the control unit. These connectors handle high signals well, making tracking better. Car makers use them for smooth communication inside cars.

Fun and Safety Systems

FAKRA connectors help with car fun and safety tools. They keep audio and video connections steady. Their strong build keeps signals flowing for cameras and screens. Engineers like them because they last long and meet rules.

Factory and Other Uses

Outdoor Routers and Smart Devices

FAKRA connectors work in outdoor routers and smart gadgets. They give safe links even in tough weather. Engineers pick them for good performance outside. Colors make setup easy, stopping wrong matches.

Fast Cameras and Machine Links

FAKRA connectors are vital for fast cameras and machine links. They send high data needed for clear pictures. Factories trust their strong design to cut signal loss, ensuring top work in hard jobs.

Advantages and Custom Solutions

Benefits of Using FAKRA Connectors

Easy to Use and Trustworthy

FAKRA connectors are simple to install. Their design stops setup mistakes. Engineers like how they fit securely. They are built strong to last long. Industries trust FAKRA connectors for being reliable.

Following Industry Rules

FAKRA connectors meet strict industry rules. This makes them work well in many places. Makers trust these connectors because they follow standards. Using FAKRA means easy fitting into systems. Industries get quality and safety with them.

Custom and Waterproof Solutions

High-Frequency and Water-Resistant Choices

FAKRA connectors handle high-frequency tasks well. Engineers pick them for great signal sending. They are waterproof, so they work in tough spots. Outdoor setups need their strong build. Industries like FAKRA's flexibility for special needs.

Automated Assembly Process

FAKRA connectors make assembly easier. Automation cuts human mistakes down a lot. Makers get better results with machines doing the work. The exactness of FAKRA helps make things right every time. Industries see more work done faster with this system.

FAKRA connectors are very useful in factories. They make sure connections are strong and last long. Factories like how exact and tough FAKRA connectors are. In the future, these connectors will be even more important. Cars will use them for easy communication. Factories will keep using FAKRA connectors to work better. Their ability to change will help new ideas in many areas.

See Also

Discovering the Advantages of Fakra Auto Connectors

The Significance of Fakra Plugs in Auto Sector

Uncovering the Flexibility of Fakra Connectors Across Sectors

An In-Depth Manual for Fakra Connectors: Benefits, Uses, and Setup Advice