Exploring Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles, ensuring reliable connections that help the car function properly. As automotive systems become more complex, the demand for advanced connectors increases. There are various types, such as blade, pin, and sealed connectors, each designed for specific needs and locations. These connectors must withstand temperature fluctuations and power variations. Choosing the right type enhances their durability and performance, reducing breakdowns and improving the overall efficiency of the vehicle.

Types of Automotive Wiring Connectors

Car connectors help vehicle systems. Each type has special uses and benefits. Knowing them helps pick the right one for cars.

Blade Connectors

Features and Applications

Blade connectors, or spade connectors, have a flat metal piece that fits into a slot. They are common in cars because they are easy to use and reliable. These connectors link wires to parts like switches. They disconnect quickly, so they’re good for places needing frequent checks.

Advantages and Disadvantages

Blade connectors are secure and simple to install or remove. But they might not work well where there is lots of shaking, as they can loosen. They need exact alignment, which can be hard in tight spots.

Pin Connectors

Features and Applications

Pin connectors have pins that fit into sockets. They connect many wires to one part in car systems. You find them in engine areas needing strong connections.

Advantages and Disadvantages

Pin connectors are very reliable with multiple connections at once. They last long even in tough car conditions but need careful alignment to fit right. Sometimes special tools are needed for putting together or taking apart.

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end straightly. Used when extending or joining different wires, you insert wires into each end then crimp them tight. Often used in fixing or setting up car wiring.

Advantages and Disadvantages

Butt connectors make a simple secure link, great for permanent setups. They're easy without special tools but not for often disconnected spots. Bad crimping can cause weak links affecting the car’s electric system.

Sealed Connectors

Sealed connectors are important in cars. They keep out water, dust, and dirt. These connectors are needed where tough conditions happen.

Features and Applications

Sealed connectors have seals to block dirt. This makes them great for engines and outside parts. They are used in engine systems and power controls. They often lock tight to stay secure.

Advantages and Disadvantages

Sealed connectors have good points. They protect well from weather, keeping connections strong. This cuts down on electric problems in cars. Their strong build works well in shaky places like cars.

But they also have downsides. Their design is tricky to put together compared to others. Special tools might be needed to fit them right. Plus, their protection makes them cost more sometimes.

Materials and How They're Made

Knowing what materials and how they're made helps connectors work well. These connectors need to handle tough conditions like heat and wetness to last long in cars.

Common Materials Used

Metal Types

Car connectors often use metals such as copper, brass, and aluminum. Copper is liked for its great ability to carry electricity and bend easily. Brass, which is copper mixed with zinc, also carries electricity well and doesn’t rust easily. Aluminum isn’t as good at carrying electricity but is light and cheap, so it’s used when weight needs cutting down.

Insulation Materials

Insulation keeps metal parts safe in connectors. Nylon, polypropylene, and thermoplastic elastomers are common insulators. Nylon lasts long and doesn’t wear out fast. Polypropylene stands up well against chemicals. Thermoplastic elastomers mix rubber’s stretchiness with plastic’s toughness for different weather conditions.

Construction Techniques

Crimping

Crimping is a popular way to put car connectors together. It squeezes a metal piece around the wire to hold tight. This makes a strong link that carries electricity well. Crimping is easy and works reliably, so it's used a lot in cars.

Soldering

Soldering melts metal to stick wires together firmly. It makes a lasting connection that carries electricity strongly but needs more skill than crimping does, so it’s not used as much where many need making.

Picking the Right Connector

Choosing the right car connectors is very important. It helps the car's electric system work well and last long. You need to think about a few things when picking.

Things to Think About

Power Needs

First, check what power is needed. Different connectors handle different amounts of electricity. For example, big power systems need strong connectors. Knowing how much power is needed helps pick the right one that won't overheat or break.

Weather Conditions

Weather affects connector choice a lot. Car connectors face heat, wetness, and rust. Sealed ones keep these away for longer use. Makers should use materials that stop shock and shaking too. Tough connectors with extra support stop wires from bending, making them last longer.

Mistakes to Watch Out For

Wrong Size

Picking the wrong size is common. Too small or too big can cause bad links and problems. The connector size must match the wire size for a good fit. Right sizing stops overheating and keeps electricity flowing well.

Bad Installation

Bad installation can mess up connections. Crimping and soldering are used in car wiring often. Crimping squeezes metal around wires for a strong hold but needs to be done right or it weakens links. Soldering melts metal to stick wires together firmly but takes skill.

In short, picking car connectors means knowing what power and weather they will face. Avoid mistakes like wrong sizes and bad installs for best performance and safety in cars.

Choosing the right automotive wiring connector is very important. Each type has special uses and helps in different ways. Picking the right one is key for what you need.

Why It Matters: The right connector makes things last longer. It stops metal from rusting, keeping electric links strong. This choice affects how well and long your car works.

How It Helps: Good connectors make cars work better and last longer. They cut down on repairs and keep cars safe to use.

Knowing these points helps you choose wisely, making cars run better and stay reliable.

See Also

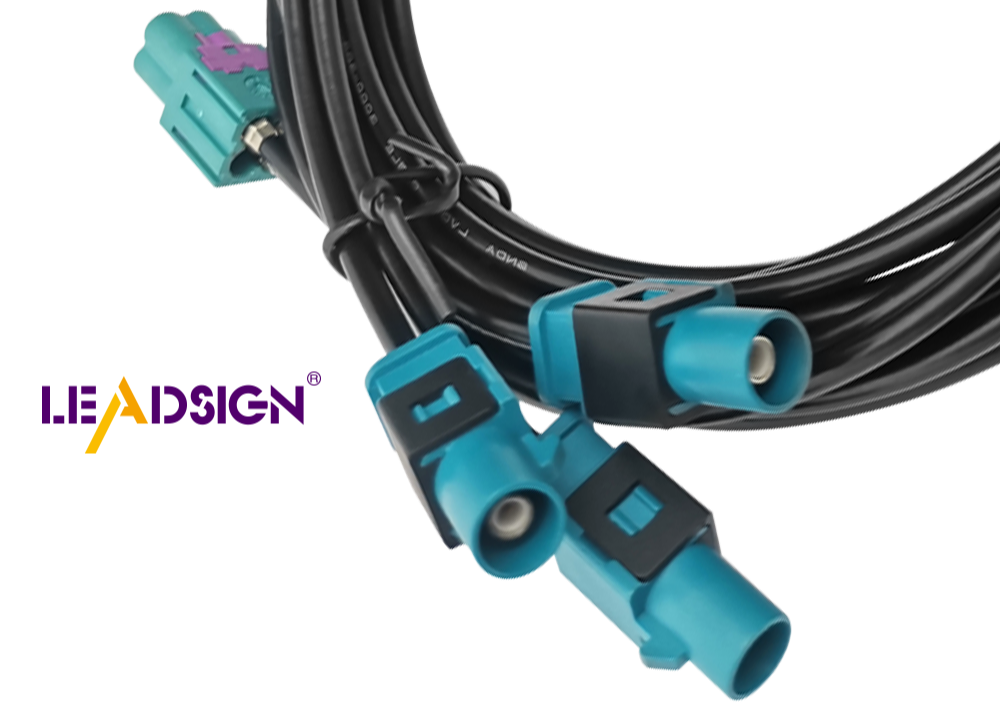

Discovering Advantages of Fakra Car Connectors

Fundamentals of HSD Connectors for Auto Sector

Significance of Fakra Car Connectors in Contemporary Autos