Exploring Automotive Wiring Connector Types

Automotive electrical connectors are crucial for vehicles, ensuring secure wire connections and preventing issues that could impact performance. There are various automotive electrical connectors types, each designed for specific functions, highlighting their significance. Modern vehicles incorporate a wide range of these connectors, tailored for distinct tasks. Understanding these connector types is essential for automotive professionals, aiding them in effectively repairing and maintaining vehicles to ensure safety and optimal performance on the road.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They link circuits to keep connections stable. These connectors help electricity move between car parts like lights, sensors, and controls. Without them, the electrical system would often break down, causing problems.

Why are they crucial in automotive systems?

Car systems need wiring connectors to work well. They stop electrical noise that can mess up the car's functions. By making sure connections are strong, these connectors help all electronic parts work together. This is important for safety features, fun systems, and engine control, making them vital in today's cars.

Historical Development

Evolution of Connector Technology

Connector technology has grown with car design changes. As cars got more electronics, better connectors were needed. At first, simple ones worked for easy tasks. But new things like GPS and control units needed better connectors. This shows how complex car wiring has become.

Key Milestones in Automotive Connectors

There have been big steps in connector development. The start of OEM automotive electrical wiring connectors was a big leap forward. Made from strong stuff, they last in tough places and resist rusting. Another step was making connectors for fast data transfer, needed for modern entertainment and driver-help systems (ADAS). These changes have made cars safer and better performing, showing how important connectors are in car tech.

Types of Automotive Wiring Connectors

Blade Connectors

Characteristics and Uses

Blade connectors, also called spade connectors, are common in cars. They have a flat shape that fits into slots. This makes the connection strong and steady. Made from brass or copper, they conduct electricity well and resist rust. Their simple design makes them useful in many car parts.

Common Applications in Vehicles

In cars, blade connectors are used in wiring harnesses and fuse boxes. They connect lights like headlights and taillights. They are also used in control modules. These connectors are easy to use and handle medium power loads well.

Pin Connectors

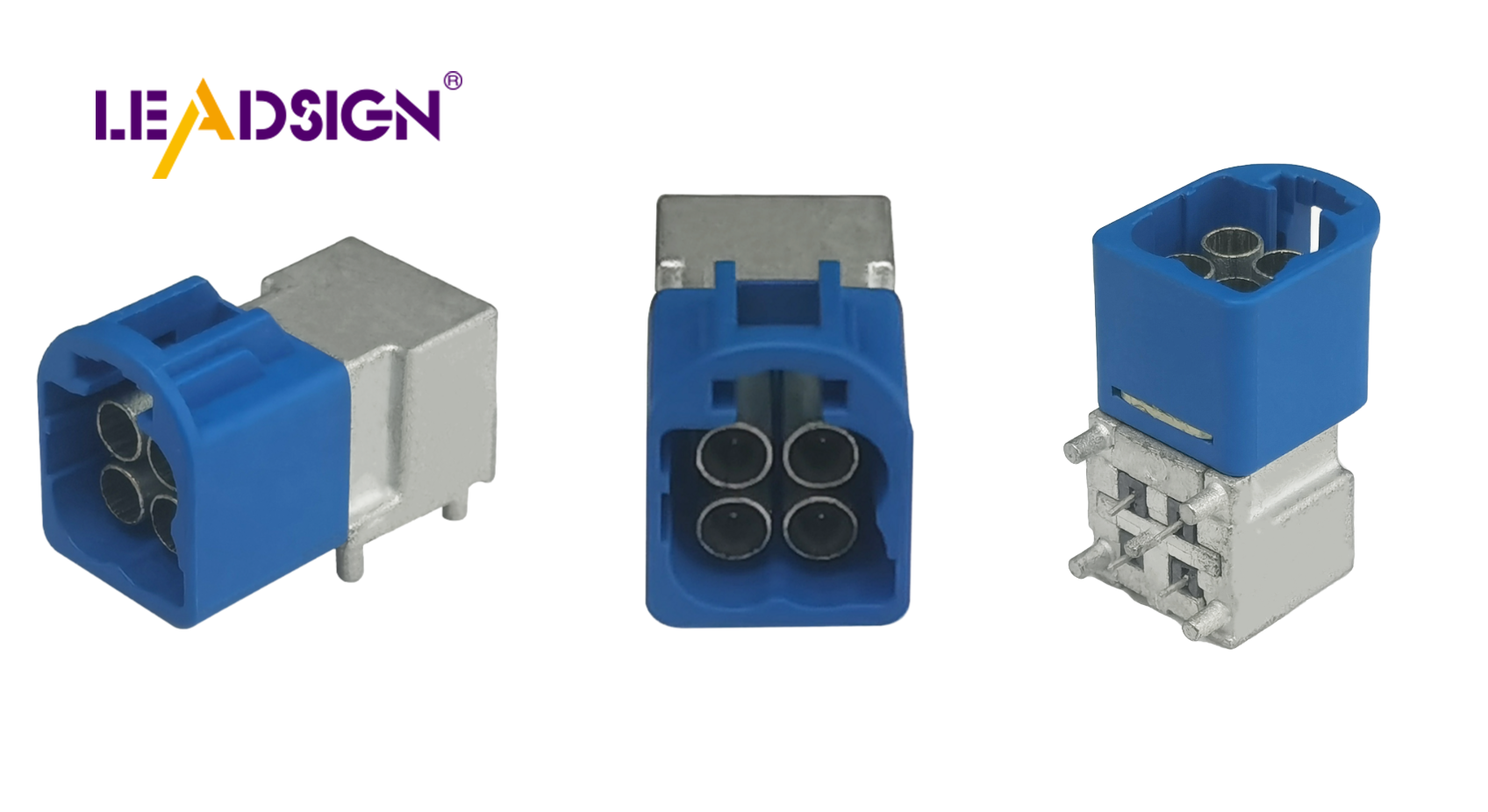

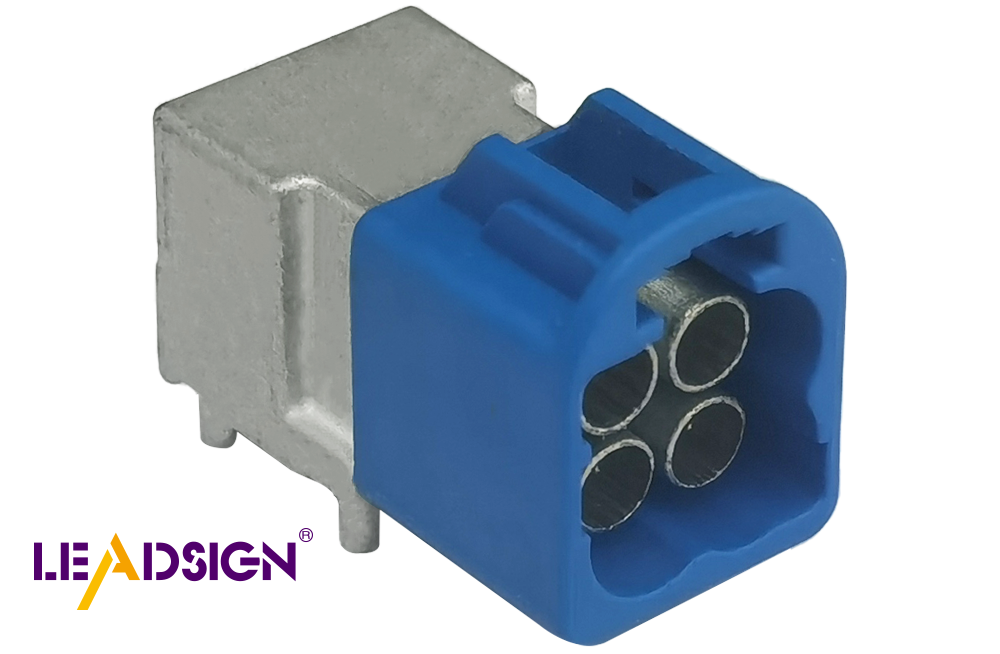

Design and Functionality

Pin connectors have pins that fit into sockets. This lets them connect many wires at once. They save space by fitting lots of wires in a small area. Pin connectors keep connections tight even with movement or vibrations.

Typical Use Cases

Pin connectors are found in engine control units (ECUs) and important systems. They are used for sensors where good data flow is key. These connectors manage complex wire setups well.

Other Automotive Electrical Connector Types

Crimp Connectors: Characteristics and Uses

Crimp connectors make strong bonds by squeezing onto wires tightly. Different types include ring terminals and butt connectors for various uses.

Common Applications in Vehicles

Cars use crimp connectors for battery links and grounding tasks. They handle high power levels and tough conditions well.

Weatherproof Connectors: Characteristics and Uses

Weatherproof connectors protect against water, dust, and temperature changes with seals that block moisture.

Common Applications in Vehicles

These are crucial where weather affects parts like engines or outside lights. Used also in off-road vehicles, they keep connections safe.

Characteristics and Selection Criteria

Material and Durability

Importance of Material Choice

Car connectors depend on the materials they are made from. The material choice affects how well they work. Material Selection for Automotive Connectors shows that plastics and metals are often used. These materials help connectors survive tough car conditions. Plastics bend easily and resist damage, while metals conduct electricity well.

Durability Considerations

Durability is key when picking car connectors. They need to last in tough places and keep working over time. Connector Durability Testing Standards stress high heat, cold, salt spray, and rust resistance. These make sure connectors stay reliable even in bad weather. For example, Deutsch connectors are strong and weatherproof, great for heavy jobs.

Electrical Performance

Conductivity and Resistance

Connectors' electrical performance depends on good electricity flow. High conductivity means low resistance, important for signals and power flow. Connector Terminal Wear and Corrosion warns that wear can raise resistance, causing signal problems or fires in high-power uses. So, choosing self-cleaning contacts is crucial.

Impact on Vehicle Performance

Connectors affect how cars work. Bad electrical performance can cause system failures. Good connectors ensure all parts work well together, helping the car run safely and efficiently by keeping low resistance.

Environmental Resistance

Resistance to Temperature and Moisture

Car connectors must handle temperature changes and moisture well. Protection Features of Automotive Electrical Connectors show these protect against heat and wetness with seals that block water out.

Longevity in Harsh Conditions

Long-lasting connectors are needed for vehicle reliability in harsh places. Environmental Considerations for Circular Connectors highlight matching them to specific needs ensures long life.

Common Problems and Fixes

Connector Breakdowns

Why They Break

Car connectors can break for many reasons. Mating force is a big problem. Too much force when connecting can harm the connector. Water and rust are also big dangers. If connectors get wet, they might rust and stop working well. Shaking or moving a lot can wear them out too. These problems can mess up electricity flow, causing systems to fail.

How to Stop Them Breaking

Stopping connector problems needs some steps. Using special grease helps reduce mating force and keeps water away. Checking them often finds early damage signs. Sealing them right stops water from getting in. Picking the right connectors for their job makes them last longer. Tests like shaking tests make sure they work before leaving the factory.

Fixing Methods

Finding Bad Connectors

To find bad connectors, look closely at them. Check for rust or broken parts you can see. Use a tool called a multimeter to test if electricity flows through it right. High numbers mean trouble. Listen for weird noises like crackling; it means loose connections. If something isn’t working, it might be because of a bad connector.

How to Fix or Change Them

Fixing connectors means cleaning and tightening them up. Use cleaner spray to get rid of rust. Tighten any loose parts so they fit well again. If fixing doesn’t help, change the connector with one just like it to keep things working right. Follow steps carefully when installing new ones to avoid more issues later on. Regular checks and changes keep car systems running well.

Picking the right car wiring connector is very important. It helps cars work well and stay safe. Good connectors make systems strong and stop problems. As technology gets better, connectors change to fit new cars. They last longer and work better now. Car experts need to know about these changes to fix cars right. Learning more about car wiring helps them choose wisely. This keeps car electric parts working for a long time without trouble.

See Also

Discovering Advantages of Fakra Auto Connectors

Fundamentals of HSD Connectors for Auto Sector

Significance of Fakra Auto Connectors in Contemporary Cars