Exploring Automotive Wiring Connector Types

Automotive electrical connectors types are very important today in the automotive industry. They help car systems work well and safely. Connectors join parts so they can talk and work together. Without them, cars would often break down, causing safety problems and expensive fixes. These connectors keep car systems strong and working right. They are made to last in tough conditions. Knowing about them helps keep cars running better for longer.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in cars. They connect different electrical pieces so they can work together. These connectors help signals move smoothly in the car. Without them, the car's electric system might have problems.

Importance in Automotive Systems

In cars, wiring connectors are very important. They make strong links that handle tough conditions like shaking, heat, and wetness. As cars get more safety tools and fun systems, we need better connectors. These help with the many sensors and gadgets in cars to keep them working well.

Basic Components of Connectors

Housing

The housing is like a cover for the connector. It keeps dust, water, and heat away from inside parts. Made from strong stuff like nylon, it helps the connector last long.

Terminals

Terminals are the main part of a connector. They make sure wires connect right to send signals well. Made from materials that carry electricity, they fit tightly to avoid losing connection.

Seals

Seals make connectors stronger by keeping dirt out. They stop water and dust from getting in too. In cars, seals are crucial for keeping connections safe even when it's hard outside.

Types of Automotive Electrical Connectors

Automotive electrical connectors are very important for cars to work well. They come in different shapes and sizes for special jobs in cars. Knowing about them helps pick the right one for each car part.

Blade Connectors

Features and Uses

Blade connectors, or spade connectors, have flat ends. This shape makes them easy to plug in and take out. They fit tightly into slots, making them good for small spaces. Blade connectors are used where there's not much room.

Common Car Uses

In cars, blade connectors are often in lights like headlights. They also link sensors and switches to send signals well. They're easy to use and trusted by many.

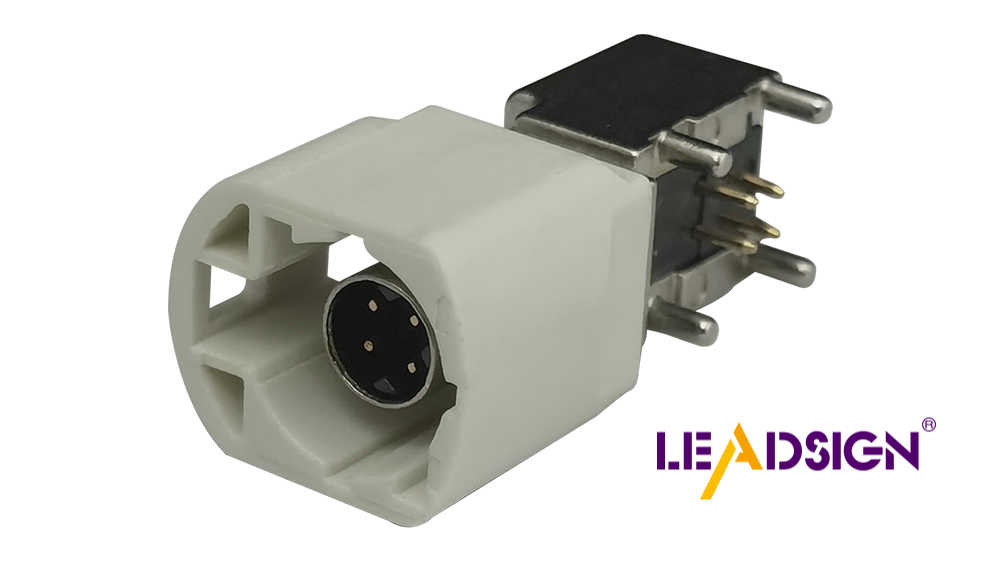

Pin Connectors

Features and Uses

Pin connectors have pins that go into sockets. This keeps connections safe for sending power and data. They can hold many wires, so they're good for complex systems.

Common Car Uses

Pin connectors are found in car electronics like engine controls. They help parts talk to each other so the car runs smoothly. They're key for modern car systems with many connections.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end safely. They're used when fixing or adding wires, keeping them connected even if pulled.

Common Car Uses

In cars, butt connectors are used in wire bundles or repairs. They keep the electric system working by holding connections tight. They're simple but very useful in cars.

Automotive Engineers say connectors are vital for special car solutions. "POF works best with automotive connectors," they say, showing how important they are for new tech like Wi-Fi networks.

Knowing different automotive connector types is key to keeping cars safe and running well.

Specialty Connectors

Waterproof Connectors

Waterproof connectors are very important in cars. They keep connections safe from water. Special seals stop water from getting inside. This keeps parts safe. Automotive Engineers say these connectors help keep cars safe and working well.

"POF works best with automotive connectors," they say, showing how important strong connections are for new car tech.

You find waterproof connectors where it's wet, like near engines and outside lights. They stop rust and short circuits, so cars run well even in bad weather.

High-Temperature Connectors

High-temperature connectors can handle a lot of heat. They're used where it's hot, like by the engine or exhaust. These connectors don't melt easily, keeping connections tight when it's really hot.

In new cars, high-temperature connectors work with many connector types. They help systems that get hot, like powertrains and turbochargers, work well. By staying strong, these connectors make sure the car lasts long and runs smoothly.

Automotive Engineers say special car solutions need tough connectors for things like Wi-Fi in smart cars. Picking the right connector is key for good performance and safety.

Picking the Right Connector

Choosing the right car connectors is very important. It helps cars work well and stay safe. This part talks about what to think about and mistakes to avoid when picking connectors.

Things to Think About

Power Needs

When picking car connectors, know the power needs. Each connector must handle certain voltage and current levels. Engineers check power needs so connectors don't overheat or break. Matching the connector to power stops problems and keeps things working well.

Weather Conditions

Weather affects which car connectors to pick. Connectors should handle tough conditions like heat, wetness, and shaking. Near engines, they need to resist heat; outside, they need waterproofing. Checking these keeps connectors strong over time.

Mistakes Not to Make

Ignoring Fit

A big mistake is ignoring if parts fit together. Wrong connectors can cause bad connections or damage systems. Engineers must check that chosen connectors fit with other parts well. This stops costly fixes and keeps systems working right.

Forgetting Quality Rules

Forgetting quality rules is risky. Good connectors follow industry rules for strength and performance. Bad ones might fail under stress, causing breakdowns. Engineers should choose high-quality ones that meet standards for lasting connections.

Picking the right car connectors means thinking about power needs and weather effects carefully. Avoiding mistakes like wrong fits or low quality ensures strong connections that last long.

Choosing the right car wiring connector is very important. It helps cars work well and stay safe. Connectors keep electric parts connected, which is needed for cars to run smoothly.

Cars now have more sensors and entertainment systems needing good connectors.

As cars get new safety features and become electric, picking the right connectors matters even more. Knowing different types and uses helps car experts make cars last longer and safer to drive.

See Also

Discovering Advantages of Fakra Car Connectors

Fundamentals of HSD Connectors for Auto Sector

Significance of Fakra Car Connectors in Contemporary Autos