Exploring Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles, facilitating communication between various car components. This enhances both performance and safety. The market for automotive wiring is valued at USD 49.73 billion in 2023, highlighting the significance of these connectors. Understanding the different automotive electrical connectors types is essential for automotive work. These connectors handle intricate wiring systems, with up to 700 connectors and over 3,000 wires in a single vehicle. Selecting the appropriate connector type is vital for each specific application.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They link circuits, letting power and signals flow smoothly. These connectors help car parts talk to each other, making the car work better. Without them, the many wires in a car would be hard to manage and could cause problems.

Why are they essential in automotive systems?

Cars need wiring connectors for many reasons. First, they make sure electronic parts connect safely and reliably. This is important for keeping the car working well and safe. Second, connectors make it easy to put together or take apart parts for fixing. Finally, they organize the complex wiring with up to 700 connectors and over 3,000 wires in cars today.

General Characteristics

Material Composition

The materials used for wiring connectors affect how well they work and last. Most are made from strong materials like nylon or plastic that resist heat, chemicals, and stress. This helps them survive tough conditions in cars.

Design and Structure

The shape and build of wiring connectors matter a lot. They come in different sizes for specific uses in cars. Designs include locks to stop them from coming loose by accident and seals to keep out water or dirt. This smart design keeps connections stable even when conditions are tough.

Types of Car Wiring Connectors

Knowing different car connectors is important for car work. Each type has a special job and features for certain uses.

Blade Connectors

Features and Uses

Blade connectors, also called spade connectors, are flat metal pieces that fit into slots. They make connecting and disconnecting wires easy. These connectors are simple and reliable. Made from brass or copper, they conduct electricity well and last long. Blade connectors are best when you need to unplug often.

Common Applications

Blade connectors are used a lot in cars. They are found in car radios, lights, and low-power parts. Their design makes them easy to put in or take out, so they’re great for temporary setups or parts needing regular checks.

Pin Connectors

Features and Uses

Pin connectors have a pin and socket for strong connections. They handle more power than blade ones. Pins made from brass or steel stay strong and resist rusting. Pin connectors are used where stronger links are needed.

Common Applications

In cars, pin connectors go in engine systems, sensors, and key parts. They hold tight under shaking or stress, good for tough spots. Pin connectors fit well where space is small because they use space smartly.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end safely with insulation. Made from nylon or PVC, they bend easily and resist heat or chemicals. Butt connectors work well for lasting connections that must be secure.

Common Applications

Butt connectors help in car wire bundles and fixes. They're handy in tight spots or when making wires longer. Their design keeps connections strong over time, perfect where toughness matters.

Crimp Connectors

Features and Uses

Crimp connectors are important in car electrical systems. They hold wires tightly by squeezing a metal piece around them. This makes a strong link that doesn't shake or rust. Crimp connectors are often made from copper or aluminum, which carry electricity well. They are easy to put in without needing to melt anything, so they’re used a lot in cars.

Common Applications

In cars, crimp connectors are used because they work well and are simple to use. You can find them in battery wires, starter motors, and alternators. These connectors are great for places needing strong links with lots of power. They can handle tough weather, making them good for engines and hard-to-reach spots.

Sealed Connectors

Features and Uses

Sealed connectors keep car wires safe from water, dust, and dirt. They have rubber or silicone seals that stop bad stuff from getting inside. This keeps them working well for a long time and stops electric problems. Sealed connectors are usually made from strong plastic that handles heat and rough conditions.

Common Applications

Sealed connectors matter where car parts face the weather. They're found in engine controls, gear systems, and lights. These keep connections safe where water or dirt might get in. Their tough build is perfect for off-road cars where protection is key.

Installation and Maintenance

How to Install

Tools You Need

To put in car wiring connectors, you need special tools. Here’s a list of what you need:

Wire Strippers: These tools take off the plastic cover from wires without breaking them.

Crimping Tool: This tool is key for crimp connectors. It squeezes the connector onto the wire tightly.

Screwdrivers: Different screwdrivers might be needed based on how the connector looks.

Heat Gun: For heat shrink connectors, this gun shrinks tubes around connections for extra safety.

Multimeter: This checks if the electrical link works right.

Steps to Follow

Get Wires Ready: Use wire strippers to take off about 1/4 inch of cover from each wire end.

Pick the Connector: Choose the right connector type for your job and wire size.

Put Wire In: Push the bare wire into the connector fully for a good link.

Crimp It Down: Use a crimping tool to press down on the connector hard for a strong hold.

Check It Out: Look at it closely to see if it’s tight and use a multimeter to check electricity flow.

Use Heat Shrink (if needed): If using heat shrink, slide it over and use a heat gun to fit it snugly.

Tips for Taking Care

Check Often

Checking car wiring connectors often keeps them working well. Here are some tips:

Look Over Them: See if there’s wear, rust, or damage on wires or connectors.

Test Tightness: Make sure all parts are tight so they don’t fail electrically.

Protect From Weather: Look for breaks in seals that could let water or dirt in.

Fixing Common Problems

Car wiring connectors can have problems sometimes. Here are some issues and fixes:

Rusty Parts: Clean rusty parts with cleaner or replace bad ones.

Loose Parts: Tighten loose parts or change broken ones for safety.

Broken Wires: Fix or swap broken wires using butt connectors for safe repairs.

Weather Damage: Swap out damaged parts from weather with sealed ones for better protection.

By doing these steps, car wiring connectors will keep working well, making sure car electric systems stay reliable and strong.

Practical Uses and Common Questions

Real-Life Uses

Car Systems Using Connectors

Car connectors are important in many car parts. They help parts talk to each other, making cars work better and safer. For example, engine connectors send signals to control fuel and spark timing. In entertainment systems, connectors join audio and video parts for music and maps. Connectors also help safety systems like airbags work fast in emergencies.

Stories from Experience

Some stories show why picking the right car connectors matters. One car maker had many electric problems because they used wrong connectors. By changing to sealed ones, they stopped water problems and made cars more reliable. Another story is about a race team that used better connectors for stronger signals. This helped their engines run better during races. These stories show how choosing good connectors helps in different situations.

Common Questions

How do you pick the right connector?

To pick the right car connector, think about some things first. Know where you will use it and how tough the place is. Sealed ones are good for wet or dusty places. Check what power it needs to handle too, like how much current or voltage it can take. The material matters; strong stuff like nylon resists heat well. Lastly, see if it's easy to put in or fix since some need special tools.

What shows a connector is bad?

Knowing when a connector is bad can stop bigger problems in cars. Signs include connections that only sometimes work right or rust on them from water damage. Loose or broken ones might not connect well, causing failures. Strange sounds or issues with connected parts can mean connector trouble too. Checking often helps find these signs early so cars stay working well.

Choosing the right car wire connector is very important. It helps cars work well and stay safe. Each connector has a special job. Picking the right one stops electric problems and makes systems work better.

People today want smart technology in their cars. They like staying connected, having fun, and being comfy inside.

By using this knowledge, people can handle the need for cool tech in cars. Trying new ideas like 3D printing can make connectors even better for what cars need now.

See Also

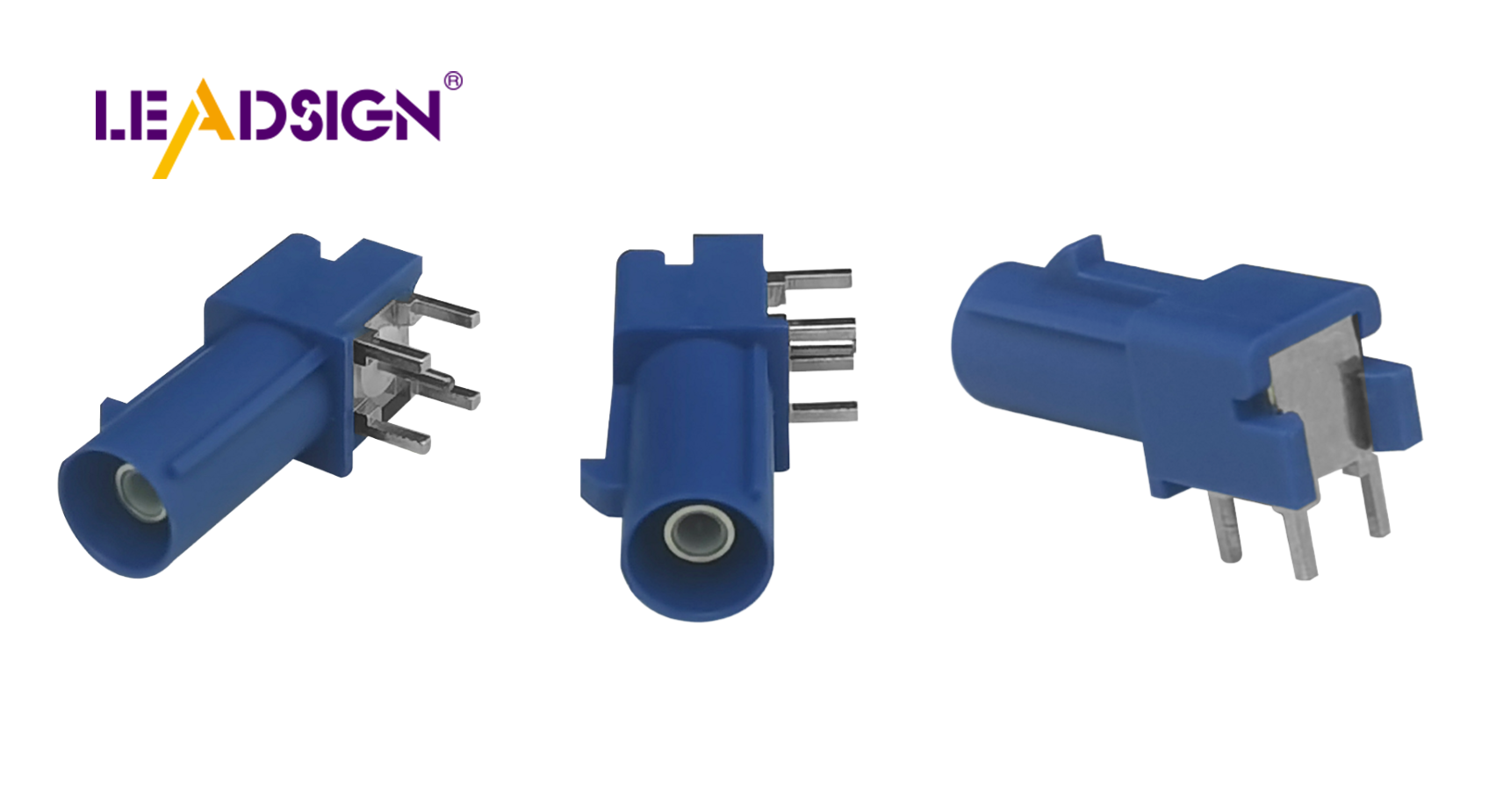

Discovering Advantages of Fakra Car Connectors

Essential Info on HSD Connectors for Auto Sector

Significance of Fakra Car Connectors in Today's Vehicles