Exploring Automotive Wiring Connector Types

Automotive electrical connectors types are essential for ensuring optimal vehicle performance. These connectors maintain robust electrical connections, allowing cars to operate smoothly. Without them, significant electrical issues could arise. Approximately 45% of connector problems stem from poor electrical contact. To prevent these issues, various types of automotive electrical connectors are designed for specific functions, ensuring vehicles remain reliable and safe.

Understanding Automotive Electrical Connectors

Definition and Purpose

What are wiring connectors?

Automotive electrical connectors are key parts of a car's wiring. They link different circuits, helping the car run well. These connectors come in many shapes and sizes for different car needs. They can be used for big machines or small lights in cars. Their design makes them easy to install quickly and securely, ensuring they work well and are important for the car's function.

Why are they essential in automotive systems?

Wiring connectors are crucial because they keep connections secure between circuits. Without them, cars would have big electrical problems that affect how they work. They stop interference that can mess up the car’s performance, making them necessary for fixing or building cars. Knowing about connector types helps keep a car’s electrical system working well.

Basic Components of Connectors

Pins and sockets

Pins and sockets are the main parts of any connector. They connect wires electrically. Pins, usually metal, fit into matching sockets to make a strong link. This setup lets electricity flow smoothly without stopping. The quality of pins and sockets affects how reliable the connection is, so they’re important in automotive connectors.

Housing and seals

The housing and seals protect connector parts from outside stuff like water or dust. Housing holds pins and sockets together firmly. Seals stop things like moisture from getting inside, which could cause rust or failure. Car connectors face tough conditions like heat or shaking, so strong housing and good seals ensure they last long.

Types of Car Wiring Connectors

Car wiring connectors are important for cars to work well. They come in different shapes and sizes for different car parts. Knowing about them helps pick the right one.

Blade Connectors

What they are and where used

Blade connectors look like flat blades. They make strong links in car wires. They're easy to use and quick to connect or disconnect. You find them in fuse boxes because they handle a lot of electricity well. Their shape keeps electricity flowing smoothly.

Who makes them

Many companies make good blade connectors. TE Connectivity and Molex are examples. They make strong and reliable connectors that meet car needs.

Ring and Spade Connectors

What they are and where used

Ring and spade connectors hold on tight. Rings fit over bolts, making strong links. Spades look like forks, so they're easy to put on or take off. They're used in battery spots because they need strong connections.

How to install them

To put these on, crimp the connector onto the wire tightly. This stops it from getting loose later on. Use the right tool so you don't break anything. Heat shrink tubing can protect it more.

Butt Connectors

What they are and where used

Butt connectors join two wires together end-to-end safely. They're round and keep wires connected well. People use them when fixing or changing car wires because they're easy to put on.

How to install them

To use butt connectors, strip wire ends first, then push into the connector. Crimp it tight with a tool for a good connection. Cover with heat shrink tubing for extra safety from water or dirt.

Knowing about these car wiring connectors is key for keeping a car's electric parts working right. Each type has special uses that help cars run better and safer by picking the right one.

Picking the Right Connector

Choosing the right automotive electrical connectors is important. It helps cars work well and stay safe. Good connectors keep things connected, from simple wires to safety features.

Things to Think About

Electrical needs

Think about what the car's system needs. Different parts need different power levels. High-power systems need strong connectors that don't overheat. Experts in automotive electrical connectors say using good ones stops problems like shorts or fires. Make sure the connector fits the system's power needs for it to last.

Weather conditions

Weather affects which connector you pick too. Cars face hot and cold places. Connectors should handle these without breaking down. Sealed ones are best where there's water or dust, stopping rust. Experts in high-voltage connector failures say they must survive tough weather without breaking.

Mistakes to Avoid

Wrong size

Picking the wrong size is a common mistake. Too small can't handle power and might overheat. Too big won't fit right and can be loose. Right size means it fits well and works best. Automotive experts say match size with wire thickness and use.

Bad installation

Bad installation can make connectors fail too. Bad crimping or sealing makes weak links that get loose later on. This causes electric problems or full failures. Using right tools and ways when installing is key for good connections. Car electrical connector specialists suggest training well to avoid mistakes.

Picking the right automotive electrical connectors means thinking about power and weather factors carefully. Avoiding mistakes like wrong sizes or bad installs keeps a car's electric parts working long and well.

Choosing the right car wiring connector is very important. It helps keep cars safe and working well. Good connectors make strong connections, stopping problems before they start. New connector technology has cool features. Some have liquid cooling for super-fast charging. Others have modular designs for different car needs. These changes show how important good connectors are, especially as more electric cars come around. As tech gets better, knowing and picking the right connectors will stay key to car safety and performance.

See Also

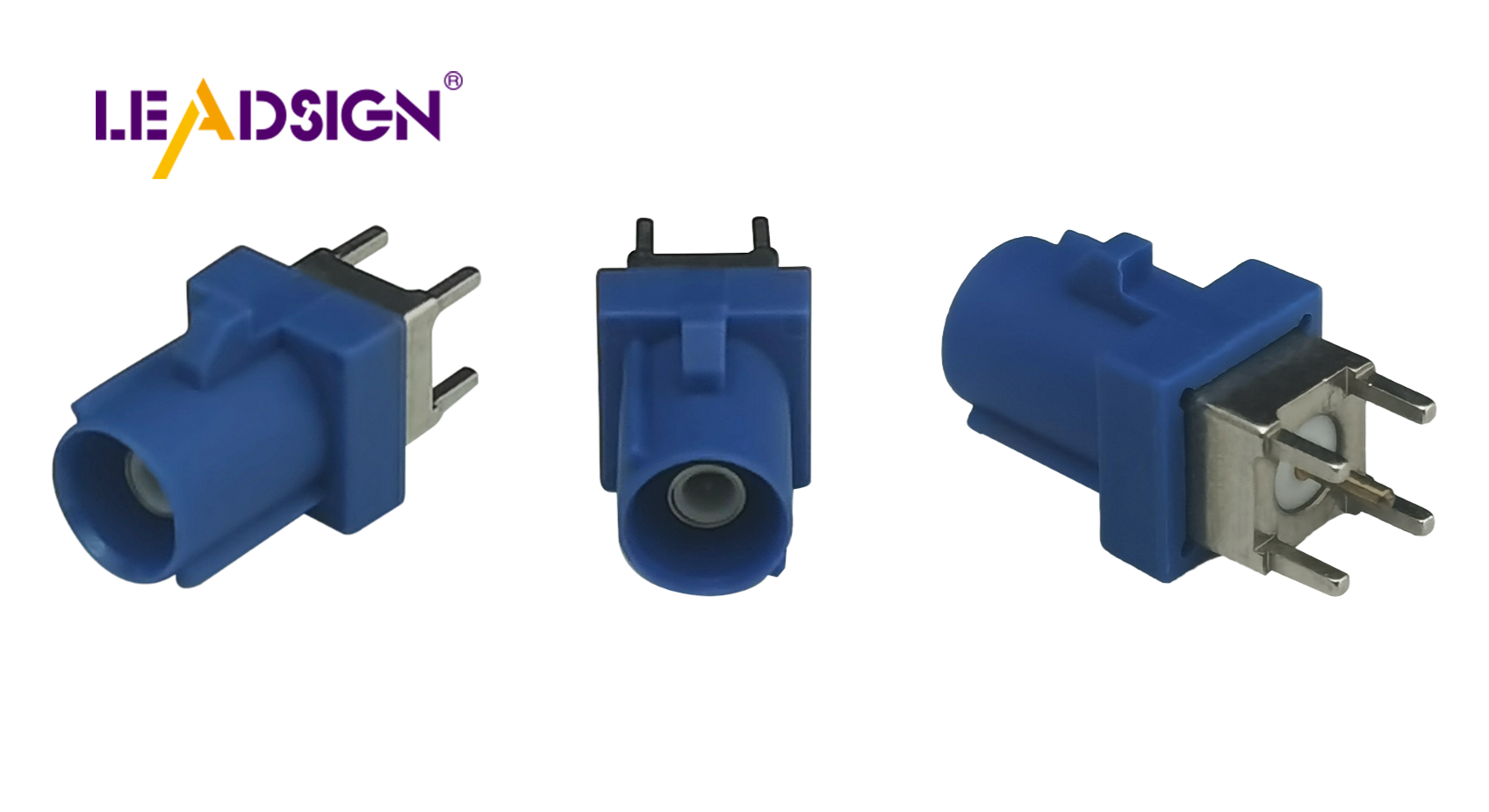

Discovering Advantages of Fakra Car Connectors

Essential Information on HSD Connectors for Cars

Significance of Fakra Car Connectors in Contemporary Automobiles