Exploring Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles. They ensure efficient electricity flow, which is essential for the proper functioning of car systems. These connectors facilitate the safe transmission of power and signals between components. However, they can fail if pins bend or wires are improperly connected. Understanding the importance of automotive electrical connectors types helps maintain vehicle performance and safety. Selecting the appropriate connectors and maintaining them can reduce the likelihood of issues, ensuring cars operate reliably and efficiently.

Overview of Car Wiring Connectors

What are Wiring Connectors?

Wiring connectors are important in cars. They help connect electrical systems in vehicles. These connectors let power and signals move through the car. They come in different shapes and sizes for various needs, from big jobs to small lights. By linking parts of a car's wiring, they keep connections strong.

Why Are They Important?

Car wiring connectors keep cars working well and safely. They stop circuits from getting hurt by shaking, heat, or rust. These connectors link many circuits while keeping out dirt and water. This is key for systems like speakers and navigation. Without them, car electronics could break down.

Parts of Connectors

Knowing connector parts helps pick the right one for a job. Each part makes sure the connector works well.

Terminals

Terminals are metal parts that touch other connectors to carry electricity. Good terminals make sure electricity flows easily, helping car systems run smoothly.

Housings

Housings hold terminals together and shield them from harm. Made of strong plastic or metal, they handle tough conditions like heat and shaking.

Seals

Seals stop water, dust, and dirt from getting into connectors. Made of rubber or silicone, they protect connections even in hard environments.

Types of Car Electrical Connectors

Car electrical connectors help vehicles work well. Different connectors do different jobs. Knowing these helps pick the right one for cars.

Blade Connectors

Blade connectors are common in cars. They have a flat metal piece that fits into a slot.

Features and Uses

Blade connectors connect safely and easily. They are simple to use and quick to attach or remove. Their design stops them from coming loose, perfect for stable connections.

Common Applications

Blade connectors are used in many car parts like headlights and tail lights. They are strong, good for places with lots of movement.

Pin Connectors

Pin connectors are another key type in cars. They have pins that fit into matching sockets.

Features and Uses

Pin connectors give precise, tight fits. They stop loose connections and handle different currents well.

Common Applications

Pin connectors are found in engine controls and sensors. They keep connections steady even when conditions change.

Butt Connectors

Butt connectors join two wires end-to-end in cars.

Features and Uses

Butt connectors connect wires simply but strongly. Easy to install with few tools needed, they ensure solid connections.

Common Applications

Butt connectors fix or extend wires in harnesses. They keep electricity flowing smoothly.

Ring and Spade Connectors

Features and Uses

Ring and spade connectors are important for cars. They make sure wires connect well. Ring connectors have a round end that fits on bolts. This keeps them tight so they don't come off easily. They are great for important jobs. Spade connectors look like forks. You can attach or remove them without taking out the bolt. Both types let electricity flow well and last long.

Common Applications

Ring and spade connectors are used a lot in cars. Ring connectors go on battery ends, ground spots, and starters. They handle big currents and tough conditions. Spade connectors join wires to switches, relays, and fuses. They are easy to use for quick fixes or setups. Knowing where to use these helps keep car systems working safely.

Picking the Right Connector

Choosing the right connector is very important. It helps car systems work well and last long. Different connectors do different jobs, so knowing what to look for helps you choose wisely.

Things to Think About

Electrical Needs

First, check what electricity the connector needs. Know how much power it will handle. Ring terminals are great for high power because they hold wires tight. This keeps electricity flowing safely. Spade connectors are good for quick changes where wires connect often.

Weather Conditions

Weather affects which connector to pick. Connectors must handle tough weather like heat and rain. Seals keep water and dirt out, so they work in hard places. Engine connectors need to stand up to heat and shaking, while others need waterproofing outside.

Mistakes Not to Make

Wrong Size

A big mistake is picking the wrong size connector. The connector must fit the wire size right or it won't work well. Wrong sizes can make bad connections and cause problems. Always check wire size and pick a snug-fitting connector.

Bad Materials

Using wrong materials can mess up connections. Different materials can react badly together, causing rust or weak links. For example, copper with aluminum can rust fast. Match materials right to avoid these problems and keep connections strong.

Picking car connectors takes careful thought about these things. By knowing electrical needs, weather conditions, and avoiding mistakes like wrong sizes or bad materials, you help car systems stay reliable.

Practical Uses and Methods

How to Install

Crimping the Right Way

Crimping right makes sure wires connect safely in cars. Use the right tool for each connector type. The tool must fit the terminal size to avoid harm. Press evenly when crimping so the wire holds tight. This stops loose connections that could cause problems.

Scientific Research Findings:

Connector Failure Rates Part 1: Different connectors fail at different rates due to insert type, heat, and power flow. Good crimping helps keep connections stable.

Keeping Connections Safe

Safe connections keep car systems working well. After crimping, look closely for any open wires or spaces. A safe connection stops dirt from causing noise or shorts. Connectors with seals block out water and dust.

Scientific Research Findings:

Environmental Sealed Connectors: Well-sealed connectors stop failures and last longer.

Fixing and Checking

Finding Bad Connectors

Finding bad connectors early stops big car problems later. Look for signs like flickering lights, rust, or damage. Check connectors often to catch issues early. Testing near where they connect can find hidden troubles.

Scientific Research Findings:

Impact of Environmental Conditions on Connector Performance: Dirt inside can cause noise and shorts; regular checks help stop this.

Fixing or Swapping Out

If a connector is bad, fix it or swap it out. For small problems like loose parts, re-crimping might work. But if there's rust or big damage, replace it with a new one that matches exactly.

Scientific Research Findings:

Core Factors for Selecting Automotive Electrical Connectors: Pick connectors made for tough conditions to stay reliable and avoid future issues.

By using these tips and methods, people can keep their car wiring strong and lasting long. Regular care and good setup are key to making electrical connectors last.

Choosing the correct car wiring connector is very important. It helps keep cars working well and safely. Good connectors make sure electricity flows without problems. This lowers the chance of things breaking. Experts say it's key to pick connectors that fit the job and conditions.

"Interviews help see if a shop matches career goals."

Using good methods in car wiring makes systems last longer. Regular checks and smart choices stop common problems. Readers should share their stories or ask questions to learn more. Your thoughts can help everyone understand car wiring connectors better.

See Also

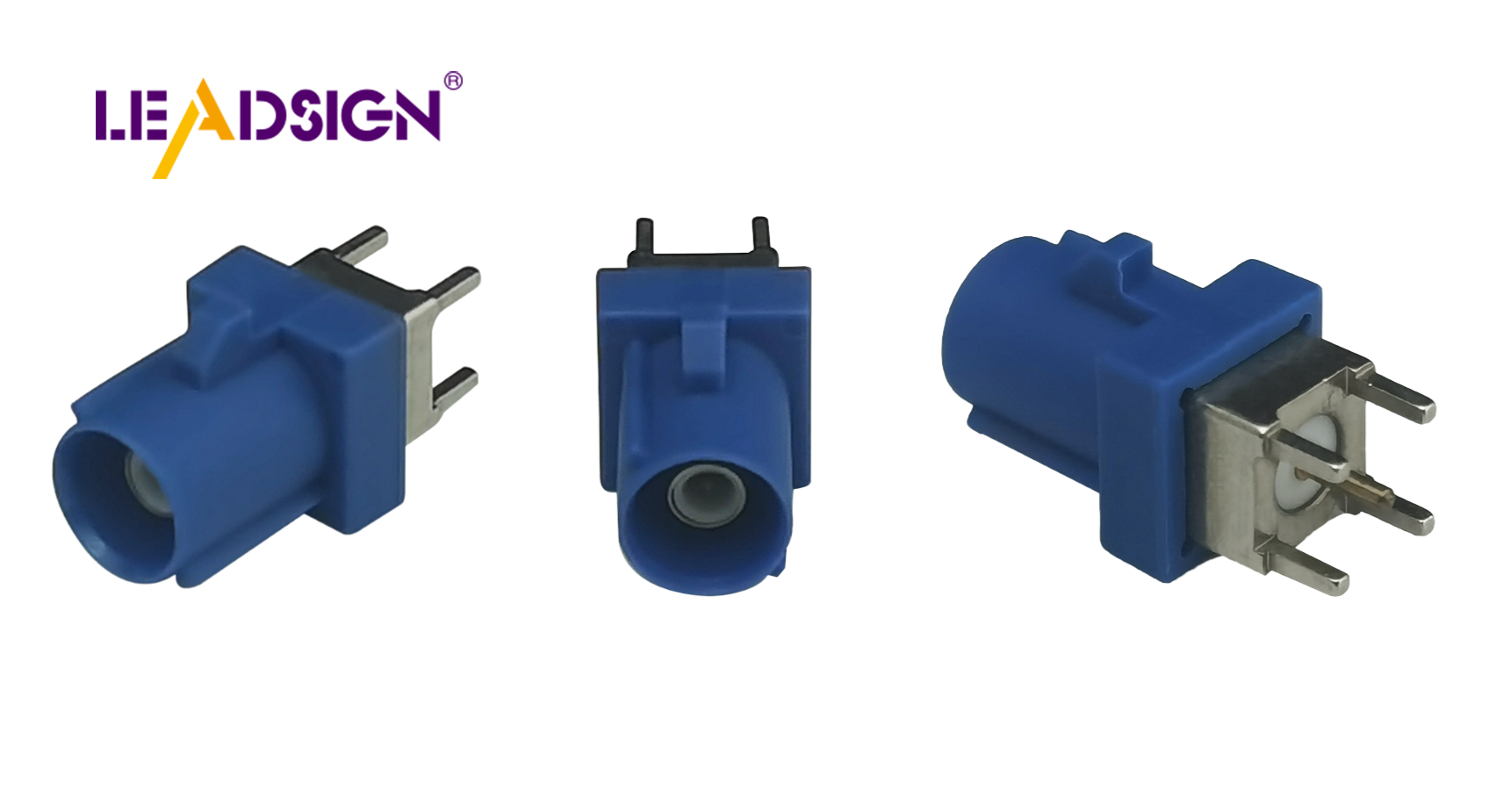

Uncovering Advantages of Fakra Car Connectors

Essential HSD Connectors in Auto Sector

Significance of Fakra Car Connectors in Today's Cars